Design Life-Cycle

assess.design.(don't)consume

Anna Minard

Professor Cogdell

Design 40A: Energy, Materials, and Design

19 November 2016

Apple Earbuds: Materials

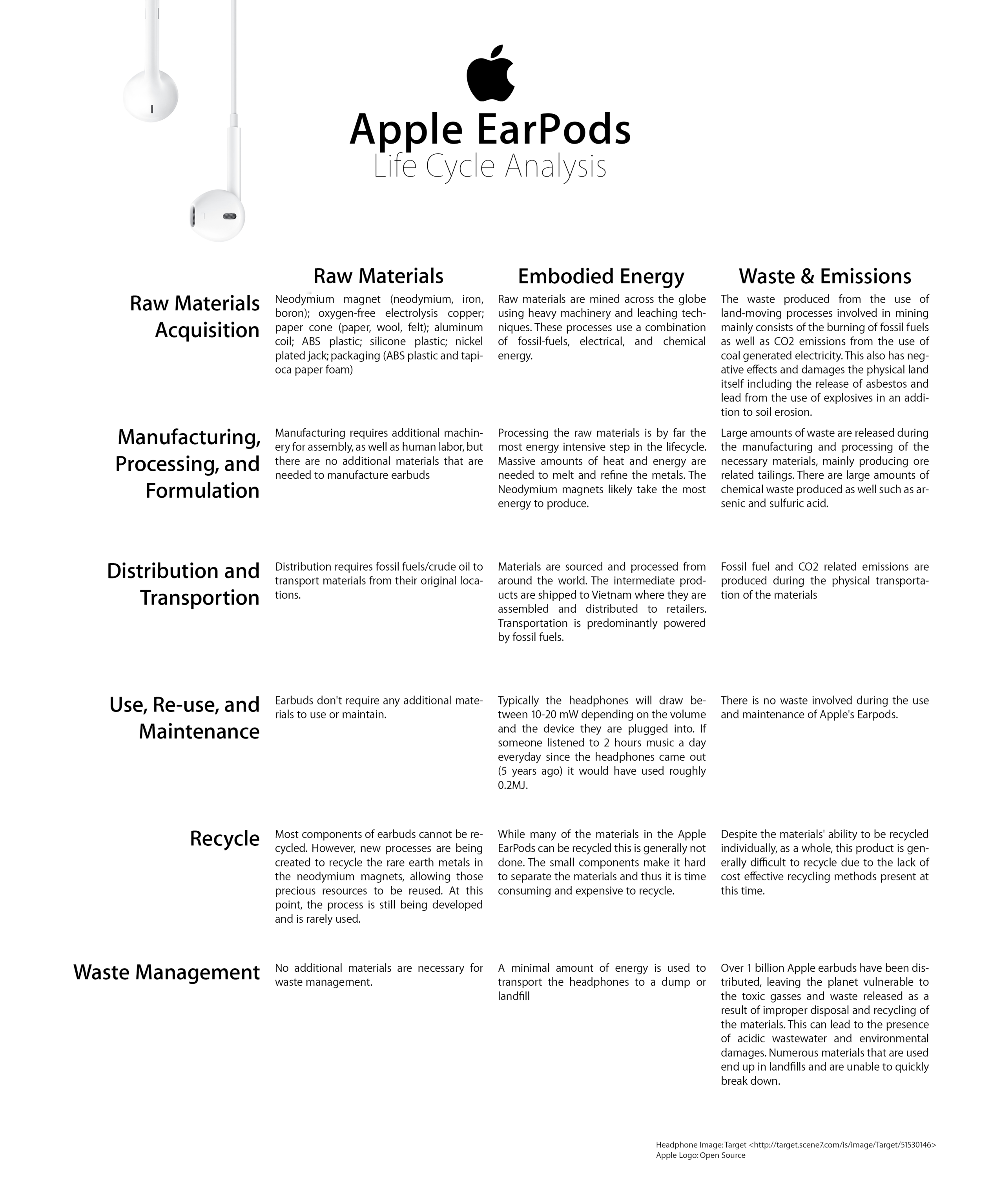

Apple earbuds are not something that people give much regard to—many people recognize them as just an additional product included in their new iPhone box, something more to keep track of, lose, or replace. The generic earbud and the new Apple-specific EarPods are all generally made of the same materials—plastics and rubber—but Apple products differentiate themselves by having a reputation of being excellently designed, with sleek profiles and a minimalist attitude. Apple’s website claim’s that their new EarPods are “ Wireless. Effortless. Magical.” However, after looking at the life cycle of Apple earbuds, it’s clear to see that their materials do more than a minimal amount of damage to the environment, and are not effortless to produce. Overall however, Apple is modifying their materials and manufacturing processes to be more environmentally conscious than before, despite the fact that their earbuds are largely regarded as disposable.

When we break down Apple’s earbuds into the individual materials, we can see that many of their resources are not as environmentally friendly as Apple would like them to be. The input plug for the earbuds (where to earbuds connect to whatever device they are used with) is essentially identical to other earbuds on the market. These jacks are most likely nickel plated with a copper core, making them resistant to corrosion while still being aesthetically pleasing. The nickel for jacks is typically found as elemental nickel in the Earth’s crust, and through the process of electroplating, it is turned into usable plating (Effectrode). The primary downfall of using nickel, however, is that there is often no substitute for it without compromising performance or increasing production costs (Nickel Metal—The Facts). The jack is connected to the earpiece with wires—oxygen-free electrolysis copper wire. This kind of wire is ideal for earbuds because of its high conductivity. Copper is found in the earth, most commonly in Arizona, New Mexico, and Utah (Mineral Commodity Summaries 2016), and is processed in an electrically charged solution of copper sulfate and sulfuric acid. This causes the copper to have an extremely low oxygen level, which has been linked to better sound quality (“Oxygen Free Copper and Its Applications”). The outermost layer of the earbud cord, which is made up of a rubber material, covers the wire. While we were unable to determine the exact type of rubber used in the cord, after comparing it to other earbud brands, we determined that it was most likely a silicone rubber, which allows for protection of the wire without inhibiting conductivity or maneuverability. Silicone rubber is made up of raw silicon, in a chain formation with oxygen (What is Silicone Made of?). The oxygen-free copper wire, surrounded by silicone rubber, lead up to the main component of the earbuds—the earpieces. These are made up of more oxygen-free wire, neodymium magnets, and a paper cone, encased in more plastic. With the help of a report designed for the Plastics division of the American Chemistry Council (10-1), we decided that the most likely plastic was ABS (Acrylonitrile-butadiene-styrene). This form of plastic is a made up of several polymers—acrylonitrile, butadiene, and styrene—and forms a rigid shape that is both light weight and easily molded in the manufacturing process. Inside the ABS plastic shell sits a neodymium magnet, which is the strongest permanent commercial magnet available. This kind of magnet is used because their strength allows for smaller, lighter-weight magnets. The neodymium magnet is an alloy of neodymium, iron, and boron, and is processed in China with a rapid solidification process (How Neodymium Magnets Are Made). Neodymium magnets, however, have a number of rare earth metals within them, making them difficult to recycle. The paper cone, used to project the sound, is actually made up of paper in combination with wool and felt, making it stiff and lightweight. The products are mixed into a pulp, and pressed into shape (Speaker Cones: Best Performance?). The wool in the paper cone is sheep wool, which needs to be sheared from the sheep, sorted into grades, cleaned and scoured, then spun and woven (How Wool is Made). The felt is most likely also wool that has been processed slightly differently, but I was unable to find any specific information regarding the exact process related to earbuds. Overall, the earbuds have no incorporated adhesives; they are comprised of closely fitting parts.

Apple has made changes to its packaging over the years to make it more environmentally conscious. Previously, earbuds were packaged in recycled paper to ensure that the wiring maintained its shape, and then encased in plastic (most likely more ABS plastic) to protect the earbuds. However, in later packaging iterations, Apple has been (most-likely) using renewable tapioca paper foam, which dissolves in water, allowing the user to dispose of the packaging without sending it to a landfill (Apple Uses Magic Dissolving Packaging for Earpods). Apple has not confirmed the exact material used in the packaging, but the environment section of their website claims that they are “switching to greener materials to create safer products and manufacturing processes. [They’re] “protecting working forests and making sure they are managed sustainably”, so it is a safe assumption that they are exploring new, more renewable resources for their packaging.

In terms of manufacturing, there are no additional materials required, other than some specified machinery to perform specialized tasks that human hands cannot complete. The copper wiring is wound into spindles by machines, and is joined to the rubber cable on yet another machine. At one particular factory in China, human employees measure and cut the cables to size. The copper coils and magnets are inserted in the plastic shell with another machine, but human hands attach the earbud caps (US Digital Media, How Earbuds are Made). Overall, the processing is a mixture of human labor and machinery work, but no additional raw materials are involved in the manufacturing.

To transport the earbuds from the factory in China requires the use of fossil fuels. While I was unable to find specifics about what method of transportation gets the earbuds overseas (whether they travel by land, sea, air, or a combo), it can be assumed that any method of transport requires fuel—oil is the number one fuel source for transportation (Fossil Fuels). This oil is pumped from underground reservoirs as crude oil, and is processed in oil refineries to create fuel oil and gasoline.

To use the earbuds also requires no additional material resources, since you simply plug them into any electronic device to use them. They require no additional energy to use, and you can use them many times before they deteriorate. Recycling of earbuds poses a challenge, however, because the earbuds are composed of so many different parts (How to Recycle Headphones). The plastic outer shell is extremely difficult to recycle, but some cities allow earbuds as part of their e-waste recycling program and there are also a few online recycling resources that are catered specifically to headphones and earbuds, like Thinksound. Scientists are currently working on a way to recycle at least part of the neodymium magnets by separating the neodymium and dysprosium with specialized ligand that binds to neodymium (Researchers…Magnets). This method can be done in as little as five minutes, but is not being widely applied yet. Earbuds can be recycled into other products, as well, if you’re willing to get crafty! Googling “earbud recycling” yields many results of DIY earbud repurposing. However, most of the non-recyclable components of the earbud end up in a landfill.

Overall, earbuds are still considered widely disposable. Most material consumption takes place with the actual physical components of the earbud, with few additional material resources coming into play throughout the life cycle of the earbuds. Other earbud/headphone companies like SkullCandy and Beats use similar materials, and none of Apple’s competitors have found more environmentally conscious materials that can be recycled or reused. Earbuds are made of materials that are not easily recyclable—like silicone rubber, magnets, and plastic—and their affordable price means that they are an easy product to simply throw away. Apple’s earbuds specifically are no more environmentally friendly than any other earbud brand, but with small changes to packaging over the years, and additional recycling resources coming into the market, it’s clear that Apple is recognizing and attempting to limit the long-term impact earbuds have. Simply acknowledging that earbuds are not being recycled in efficient ways—and that the materials that are being used in them are not sustainable in the long-term—means that companies will be forced to change their materials, hopefully making the cheap, disposable earbud into a more durable, environmentally conscious device.

Works Cited

Bennett, Sophia. "How To Recycle Headphone." Recycle Nation. N.p., 10 Sept. 2014. Web.

"Chapter 10." Solid and LIquid SIlicone Rubber: Material and Processing Guidelines. N.p.: WACKER Chemical Manufacturers, n.d. 10-1-0-3. Print.

Dorsey, Inc. Piccirilli. "Fossil Fuels." Fossil Fuels | EESI. Environmental and Energy Study Institute, n.d. Web. 30 Nov. 2016.

"Environment." Apple. N.p., n.d. Web. 30 Nov. 2016.

How Earbuds Are Made. Dir. US Digital Media. YouTube.com. N.p., 13 Jan. 2013. Web. 21 Nov. 2016.

"How Neodymium Magnets Are Made." K&J Magnetics Blog. N.p., n.d. Web. 30 Nov. 2016.

"How Wool Is Made." How Wool Is Made - Material, Manufacture, Making, History, Used, Processing, Parts, Components, Structure. N.p., n.d. Web. 30 Nov. 2016.

Inc, Msash. "Oxygen Free Copper and Its Applications." Custom Cable Oxygen Free Copper and Its Applications Comments. N.p., n.d. Web. 30 Nov. 2016.

Milton, Jim. "Speaker Cone Material: Best Performance?" HomeTheaterHifi.com. N.p., 03 Nov. 2015. Web. 30 Nov. 2016.

"Nickel Metal - The Facts." Nickel Metal - The Facts. N.p., n.d. Web. 30 Nov. 2016.

Stone, Maddie. "Researchers Devise a Simple Method For Recycling Rare Earth Magnets." Gizmodo. N.p., 21 June 2015. Web. 30 Nov. 2016.

Taylor, Phil. "Jack Plugs – The Gold, the Brass and the Cheap." Effectrode. Effectrode, 29 July 2014. Web. 30 Nov. 2016.

Thinksound. "Recycling. Rewarded." Thinksound. N.p., n.d. Web. 30 Nov. 2016.

Truta, Filip. "Apple Uses Magic Dissolving Packaging for EarPods." Softpedia. N.p., 11 Oct. 2012. Web. 30 Nov. 2016.

United States. Geological Survey. Copper. N.p.: Mineral Commodity Summary, 2016. Jan. 2016. Web. Nov. 2016.

"What Is Silicone Made Of?" Shin-Etsu SIlicone. N.p., n.d. Web.

Benjamin Hough

Christina Cogdell

Des 40A

December 1, 2016

Embodied Energy of the Apple EarPods

By themselves, headphones are not all that impressive. There is some plastic, some wires, and two speakers. It is Apple’s incredible attention to detail and design that has made these small white headphones the iconic product they are today. The Apple EarPods are easily recognizable and be found in nearly in country around the world. Part of what makes them so recognizable (other than the design) is the sheer number of the headphones in existence. To date, Apple has sold over 1 billion iPhones each of which has come with a pair of headphones and this does not even include the headphones sold individually (Costello). At this scale the resources and energy going to produce become meaningful. By examining the embodied energy involved in the life cycle of the Apple EarPods we can see that Apple is trying to use more eco-friendly materials but not at the cost of performance.

I. Overview of all the materials in the product

The Apple EarPods are a surprisingly simple product in terms of its components. They contain a copper wire to carry the current to the speaker driver. The driver contains a copper coil, a Neodymium permanent magnet, a paper cone, and an aluminum frame to hold everything in place. The current in the coil creates a magnetic field that interacts with a magnet and causes the cone to vibrate and produce sound waves. To complete the product, there is a plastic housing around the speakers, rubber wire insulation, and a headphone jack at the end (Hartt).

II. Energy of acquisition and processing of metal components.

The concentration of copper in mines has steadily decreased as the richest deposits are used up. This means that more energy must be expended to obtain the same amount of copper in the past. Between 125 and 210 tons of material must be mined per one ton of refined copper produced (Ayres et al. 15). There are two main sources of copper, sulphidic ores and oxidic ores from which 90% and 10% of the copper is produced respectively. The sulphidic ores have large amounts of chemical energy stored in the molecular bonds which can be utilized during smelting. If the sulphur content is high enough then no additional fuel may be needed. “Instead, smelting and fire refining is fuelled by the energy provided by the sulphur within the ore” (Copper Life Cycle Analysis ). Not needing additional fuels does not mean smelting copper is energy efficient. Sulphur as an energy source is non-renewable and is used up in the process. To achieve a higher purity of copper needed for electronics and especially for audio electronics electrolytic refining is used. This requires electrical and chemical energy from the acids involved (Ayres et al. 21).

The next metals to be assessed are the three involved in the Neodymium magnets: Iron, Boron, and of course Neodymium. Magnets are a critical component in any speaker. In the Apple EarPods, Neodymium magnets are used because their mass to strength ratio is extremely high compared to ferrite magnets, allowing for smaller, lightweight EarPods. Using ferrite magnets would require less energy to produce but headphones would be a bit bulkier. Approximately 80% of the world’s Neodymium magnets are produced in China (Benecki 12 ). Mining and refining Neodymium is an energy intensive process since most supplies are found in low concentrations it requires complex extraction and purification methods (Broehm 13). Electricity and fossil fuels are used at all stages of processing Neodymium. It is estimated that 75% of China’s electricity is generated by coal and the rest is from hydro (Koltun and Tharumarajah). The raw materials are mixed in a vacuum induction furnace which are power hungry, operating at 6 kW to 530 kW (“Vacuum Induction Melting”). After it cools the metal is ground up into powder pressed into a die, sintered, machined into its final shape and then magnetized (“How Neodymium”). All of these steps primarily use electricity which again is mostly generated from coal.

The last major metal material in the headphones is Aluminum. Like any metal, it must be mined and in the case of Aluminum, bauxite is the ore that is mined. The “[e]nergy consumption in the mining process is either in the form of fossil fuel combustion such as diesel, gasoline, natural gas and coal, or in electricity use. Approximately 150 MJ, or 0.14 MMBtu, of primary energy is used to produce one dry metric ton of bauxite” (“Aluminum: The Element” 20). Once mined the bauxite is refined into an intermediate product called alumina. Alumina refinement requires energy from a lot of the same sources as for mining just substantially more of. “Approximately 14,200 MJ, or 13.5 MMBtu, of primary energy is used to produce one metric ton of metallurgical alumina” (“Aluminum: The Element” 22). The final stage is to convert the alumina to aluminum through electrolysis, approximately “47 MJ goes into the molten electrolysis of 1 Kg of the metal” (“Aluminum Life Cycle”). These stages are for new Aluminum however and Aluminum easily recycled which saves about 95% of the energy used by the previous stages (“Recycling of aluminium”). Apple states that it uses as much recycled material as possible and in 2015 Apple recycled 4.5 billion pounds of Aluminum from all its products (“Environmental Responsibility” 17). Where it can Apple is doing a good job of saving energy.

III. Energy of acquisition and processing of plastic components

The exact type of plastic used for the Apple EarPods could not be found. Acrylonitrile butadiene styrene (ABS) is commonly used by other headphones so it is our best guess for what Apple makes theirs out of. ABS is a plastic derived from crude oil and natural gas. Detailed energy breakdowns were available for ABS plastic and it is known that 56% of the embodied energy comes from natural gas, 32% from petroleum 8% coal and 2% nuclear. Most of the energy goes into the material itself (50%), with the rest going to the process (48%) and transportation (2%) (Franklin Associates 110-114).

IV. Embodied Energy of the Packaging

With the packaging, it is clear that Apple is trying to use more sustainable materials. Starting with the fifth generation iPod Touch headphones a portion of the packaging is biodegradable. A “renewable tapioca paper foam material” is used to protect and secure the headphones in the packaging (“Apple”). No resources about the energy needed to produce tapioca paper foam could be found, however, several mentioned a lower carbon footprint than packaging using plastic or paper pulp and lower carbon footprint generally correlates to lower energy use (“Sustainability”).

V. Energy of distribution

Where Apple sources its raw materials could not be found. Looking at the top producers of the raw materials gives a good idea about the amount of transportation needed to create the EarPods. The top producers of copper are Chile and China. Aluminum primarily comes from China, Russia, and Canada. Neodymium is from China with some from the U.S. (U.S. “Mineral Commodity”). All the secondary materials must be shipped to Vietnam where they are assembled and packaged (Ha). From there the headphones are shipped across the globe to Apple’s distributor. Much of the transportation is done by cargo ships, trucks, and trains which are all powered by fossil fuels.

VI. Energy of Use

The Apple EarPods consume very little power during their daily use. Typically the headphones will draw between 10-20 mW depending on the volume and the device they are plugged into (Rockwell). If someone listened to 2 hours music a day every day since the headphones came out (5 years ago) it would have used roughly 0.2MJ. As a comparison, this about ⅙ the energy needed to brew 1 liter of beer according to WolframAlpha. It should be noted however that this energy comes from the battery of the device which is typically a tertiary energy source meaning most of the energy is lost when converting from coal to electricity to chemical and back to electricity.

VII. Recycle and Waste

While many of the materials in the Apple EarPods can be recycled this is generally not done. The small components make it hard to separate the different materials and thus it is time consuming and expensive to recycle.

VIII. Conclusion

Apple is leading the way when it comes to creating more eco-friendly products, especially in the tech field. Apple’s use of recycled products is a huge energy saver and it is great to see Apple influencing other companies to follow suit. However when it comes down to the performance demanded by consumers and the competition from other products Apple is not willing to compromise certain material choices as was seen with the Neodymium magnets.

Works Cited

"Aluminium Life Cycle." Aluminium Design. N.p., n.d. Web. 20 Oct. 2016.

"Aluminum: The Element of Sustainability." (n.d.): n. pag. The Aluminum Association, Sept. 2011. Web. 10 Nov. 2016.

"Apple and the Environment." Apple. N.p., n.d. Web. 28 Nov. 2016. <https://web.archive.org/web/20121011004829/http://www.apple.com/environment/>.

Ayres, Robert U., Leslie W. Ayres, and Ingrid Rade. The Life Cycle of Copper, Its Co-Products and By-Products. Tech. no. 24. N.p.: n.p., n.d. IIED. Web. 15 Nov. 2016.

Benecki, Walter T. "The Permanent Magnet Market." (2013): 12. Web.

"Copper Life Cycle Analysis for Products." European Copper Institute. N.p., n.d. Web. 15 Nov. 2016.

Costello, Sam. "How Many IPhones Have Been Sold Worldwide?" Lifewire. N.p., 3 Nov. 2016. Web. 30 Nov. 2016.

Environmental Responsibility Report 2016. Rep. Apple Inc, Sept. 2016. Web.

Franklin Associates. Cradle-To-Gate Life Cycle Inventory of Nine Plastic Resins and Four Polyurethane Precursors. Rep. N.p.: n.p., n.d. American Chemistry. Aug. 2011. Web.

Ha, Peter. "Purported Redesigned Apple Earbuds Leaked In Vietnam." TechCrunch. N.p., 2 Sept. 2012. Web. 10 Oct. 2016.

Hartt, Brett. "Apple EarPods Teardown." IFIXIT. N.p., 18 Sept. 2012. Web. 26 Oct. 2016.

"How Neodymium Magnets Are Made." K&J Magnetics. N.p., n.d. Web. 26 Oct. 2016.

Koltun, Paul, and Ambavalar Tharumarajah. "Life Cycle Impact of Rare Earth Elements." Life Cycle Impact of Rare Earth Elements. Hindawi, 4 May 2014. Web. 12 Nov. 2016.

"Recycling of Aluminium." Hydro. N.p., 21 Jan. 2013. Web. 01 Dec. 2016.

Rockwell, Ken. "IPhone 5 Audio Quality Measurements." Ken Rockwell. N.p., Jan. 2013. Web. 25 Oct. 2016.

"Sustainability." Paperfoam Biobased Packaging. N.p., n.d. Web. 28 Nov. 2016. <http://www.paperfoam.com/sustainability/>.

United States. Department of the Interior. Mineral Commodity Summaries 2016. Reston: Geological Survey, 2016. Web.

"Vacuum Induction Melting and Casting Furnaces." (n.d.): 8. ALD Vacuum Technologies. Web.

Joseph Adorante

Des 40A

Apple Earpods Life Cycle: Waste

Apple Earpods are the white in-ear headphones that can be seen in many different environments all over the world. They come with all iPhones and are therefore are mass produced as well as widely distributed. Their production as well as existence has been widely impactful regarding their popular use among those listening to music or talking on their iPhone or apple device. The existence of this product has also been felt regarding its environmental impact which can be seen during its life cycle. The life cycle of a product focuses on the environmental impact that it has from stages as early as the physical extraction of materials to the very end such as the product ending up in a landfill or even in the ocean. Apple appears to be environmentally conscious, doing yearly reports on energy use and claiming to be pushing towards using only renewable energy (“Renew And Recycling”). They seem to be recognizing the large scale impact that they could be having due to the increasing popularity and mass production of their products. Despite such efforts, through researching the waste produced during the life cycle of Apple’s Earpods, it can be noted that this product does in fact produce large quantities of damaging waste while still taking a step forward to cut down on its negative environmental impact during its overall life cycle.

The first step towards making Apple Earpods is the acquisition and transportation of materials. Regarding the issue of waste in terms of Apple’s earpods, this stage produces mostly fossil fuel related emissions while having negative effects on physical land as well. A main ingredient in this product is the neodymium magnet that is found within each earpod, acting as the key component of the speaker which releases sound (“Materials Used In Apple Headphones”). These magnets are composed of neodymium, iron, boron, aluminum, niobium, and dysprosium. Neodymium is found in LREE related minerals such as carbonates and bastnäsite (“How Neodymium Magnets Are Made"). These can be from Australia, Brazil, U.S., China, India, Malaysia, South Africa, Sri Lanka, and Thailand. Where the element is from depends on the LREE related mineral. Once they are mined using chemical or physical extraction processes, these minerals are then transported by means of fossil fuels, to then be processed and refined (“How Neodymium Magnets are Made”). Another ingredient in the neodymium magnet is Iron. Iron is found within the Earth’s crust and is both mined and processed in China, Brazil Australia, India, and Russia. Mining is quite damaging to the Earth due to land displacement and is generally powered by fossil fuels as well (“Iron”). Another ingredient found in the magnets is Boron. Boron is generally present in evaporite minerals. Turkey is currently the leading producer of Boron, followed by Chile, Argentina, and Russia (“Boron Production Top Countries 2010-2015 |Statistic”). Boron is mined in order to later be physically processed and refined. Following Boron is Bauxite, which is what Aluminum is extracted from. Aluminum is also a key component in earpods due to the use of an aluminum coil. Bauxite is physically acquired through methods such as mining and drilling. This is done either with excavators and scrapers or with explosives (“Ever Wonder How Aluminum Is Made?”). It is then carried by heavy machinery to be processed and refined. About .25% of global production of aluminum is from Australia. Australia, China, and Brazil are the top Bauxite producing nations, for it is generally found in the sub-tropics (“Largest Bauxite Producing Country 2015 | Statista"). The next ingredient is Niobium which is naturally occurring in Pyrochlore. Pyrochlore is generally mined in Canada, Brazil, Nigeria, Australia, and a few countries in central Africa as well (“Niobium Processing”). This is done by open-pit mining. Following this, the pyrochlore is then cut in segments to be transported. Underground mining methods can be used as well. Dysprosium, the final ingredient for the neodymium magnet is known be naturally occurring in numerous sources. Those sources include xenotime and monazite as well as placer deposits, uranium ores, and weather clay deposits (“Dysprosium, REE Handbook”). Dysprosium is found within the Earth’s crust. It is obtained through the act of mining in heavy-minerals sands by surface placer methods. It is mined using floating dredges which separates the heavy materials from lighter materials. Ores are separated with large moving equipments such as scrapers, loaders, bulldozers, and water jet techniques. The mining can be done in South Africa and the United States as well as Kazakhstan and China (“Dysprosium, REE Handbook”). Another material that helps make up these earpods is oxygen-free electrolysis copper wire. This helps make up the wires that bring signs from the device to the sound producing part of the earpods. These wires are mainly composed of copper. Copper is extracted out of the ground through the use of open-pit mining which is done by drilling as well as with explosives. Not only does this create land displacement and the negative effects associated with that, but dynamite explosions release lead and asbestos into the air and surrounding environment (“Copper”). Drilling is powered by fossil fuels, contributing to the waste that is created by the physical movement and displacement of rocks and minerals involved in the process of mining. Copper is generally produced in the U.S. and Chile but is made is Canada, Russia, and China as well (“Copper”). The transportation from one location to the location of processing and manufacturing is powered by fossil fuels. Nickel is another material that is needed for the manufacturing of this product, for it used to make the jack that is inserted into an audio input so that the earpods can be used. Like copper, nickel is extracted from the ground through the physical act of mining. Nickel is mined in two different ways depending what type of ore it is found in. The mining techniques for sulfide include underground techniques. Mining of laterites is an earth-moving process, using large shovels, front-end loaders to extract the nickel rich material and discard large boulders and waste material (“Nickel Processing”). The ore is then transported to a smelter. This produces even more fossil fuel emissions. Mining can negatively effect land such as by soil erosion (“Nickel Processing”). A paper cone is used for the actual projection of sound (“Materials Use In iPod Headphones”). This is composed of wool and felt. Wool is acquired from sheep, for their wool coat is cut off once a year. There is no waste produced during the acquisition of the wool (“Wool”). Meanwhile, felt can be acquired from the shearingof sheep’s wool. Felt is specifically made from polyester and wool (“Felt”). Meanwhile polyester is made from coal, air, water, and petroleum, needing the burning of carbon in order to exist (“Felt”). The outer casing and shell of the earpods is made of ABS plastic. ABS plastic is composed of “oil based resources” but I was not able to find out the specifics regarding its composition as well as the acquisition of those ingredients (“PLA VS. ABS PLASTIC”). The packaging consists of plastic as well and also includes renewable tapioca paper foam. Starch is extracted from potatoes and is then used to created tapioca paper foam, relying on only the growth and presence of potatoes (“Paperfoam"). During the process of material acquisition, it is clear that Apple could be much cleaner regarding waste and emissions, although there is little toxic waste produced during this stage. Much of the waste produced is Carbon emissions related, due to smelting and the operation of heavy machinery. Following the acquisition is the processing of such materials, and specifically the waste produced during the second phase.

The second stage is the manufacturing, processing, and formulation of such materials to then physically compose and assemble the product. In order for copper wires to be used in earpods, copper is removed from an ore by means of fossil fuels. Tailings are left over once the ore is separated. This then produces a copper concentrate which is put into a furnace which is powered by fossil fuels (“Copper”). Sulfur is released during this process. Copper is then refined in a furnace, releasing more fossil fuels to do so. Wasted minerals are then collected to be processed and recovered. Sulfuric acid is recovered as well to minimize toxic waste. Tailings are then produced from the smelting that is done. The wastes produced during the processing of copper can contain large quantities of arsenic, lead, and other chemicals which can have negative effects on an individual’s health (“Copper”). In order to process Sulfide ores, to ultimately produce and refine nickel, tailings are produced during the extraction process. Large amounts of sulfur are released during this process as well. Copper and sulfur is produced during the treatment of nickel in an attempt to capture and reuse waste produced, specifically tailings. Pollution problem due to release of sulfur. From Laterite ores. This requires significant energy input, fossil fuels. Electric furnaces are used to strip oxide down to metal (“Nickel Processing”) In addition, nickel plating is done through the burning of fossil fuels. The processing of wool is rather wasteful. There is hard waste which is created by the spinning and twisting of the wool. This requires a lot of work to be reprocessed and is considered to be worthless due to this. The finishing waste in the production of wool includes short clippings, sample runs, and defects. Because this has a lot of variation, it needs to be sorted through and cleaned to determine which can be used so it is generally the least usable group of waste (“Wool”). Felt is another component of Apple’s Earpods. The amount of waste produced during the production of felt is limited. Pieces of felt are cut off when the edges are trimmed. Such pieces of felt become covered in grease and oil and then cannot be used and are then thrown away and ultimately end up in a landfill (“Felt”). The paper cone is surrounded by the plastic shell of the EarPods which is made up of ABS plastic. I was unable to find clear information regarding ABS plastic processing and the waste produced during the process. The processing of tapioca paper foam has a “carbon footprint 85% lower than comparable packaging of plastic or paper pulp” (“Sustainability | Paperfoam Biobased Packaging”). This is a result of low water consumption during production, low weight of the packaging, high energy efficiency and the, use of renewable raw materials and toxic-free waste products. The processing and manufacturing of many of the necessary ingredients and materials is quite damaging regarding the amount of waste produced, but given that some of the materials used are relatively environmentally friendly, it can be seen that Apple is attempting to be much cleaner in terms of the environment impact of their products, specifically the earpod.

The distribution and transportation of this product is relatively vague. This product is widely distributed across the globe, meaning that it had to be physically transported to that region or country. Generally speaking, that means that fossil fuels were involved, so therefore the waste associated with the distribution of this product is solely related to fossil fuel emissions. Regarding the topic of use and maintenance, Apple’s earpods succeed in that they do not produce any waste.

Given how widespread this product is, one would hope is that there is a way to recycle it in an attempt to minimize a potentially massive amount of waste. Apple gives consumers the opportunity to recycle iOS devices by listing the numerous opportunities on their website (Apple). Earbuds can technically be recycled, but only as electronic waste, meanwhile “most curbside programs do not accept electronic waste and therefore will not take headphones” (“Recycle Nation”). What they fail to do is to offer an option to recycle their earpods, allowing this product to meet quite a destructive and wasteful end of its life cycle. This demonstrates how this product produces an easily avoidable amount of waste during the part of the life cycle, for this could be avoided if recycling was taken more seriously, by the manufacturer, Apple.

The main problem with this product, following their inability to be properly recycled, is the sheer number of headphones that are disposed of in landfills. 1 billion Apple iPhones have been sold from the original iPhone which was released in June of 2007 to the iPhone 6S which was released in March of 2016 (Lifewire). With each iPhone comes a USB cord as well as a USB power adapter and a pair of their earbuds (“What’s Inside The Box?”). This means that over 1 billion pairs of Apple earbuds have been sold and distributed. As stated by Micah Broehm in “Neodymium And The Global Headphone Market”, a student at the Graduate School of Asia Pacific Studies, it is important properly dispose of neodymium due to the “waste gas containing dust concentrate, hydrofluoric acid, sulfur dioxide, and sulfuric acid,” as well asradioactive waste residue (Broehm, 47). This highlights the environmental impact that these earpods are having by not being disposed of properly. Neodymium and dysprosium may be recyclable in the near future, “If you have the right materials, you can do this separation in five minutes, whereas the liquid-liquid extraction method [used in mining] takes weeks,” according to Maddie Stone (“Researchers Devise a Simple Method For Recycling Rare Earth Magnets”). Apple Earpods are especially destructive and wasteful regarding the waste management segment of the lifecycle, for they release toxic wastes and do not break down easily.

Five out of the six stages of the life cycle of Apple’s EarPods involves some sort of waste, which highlights how Apple is in fact failing regarding their attempts and claimed increase in environmental awareness. They produce large amounts of waste during almost every stage and continue to produce excess toxic wastes when not recycled, which is most of the timedue to the difficulty involved in the recycling of earbuds in general. This could definitely be improved upon, for minimizing the amount of waste produced is crucial to successfully preserving this planet.

Work Cited

BCG Senior Vice President. "Boron Production Top Countries 2010-2015 |Statistic." Statista. US Geological Survey, n.d. Web. 29 Oct. 2016

BCG Senior Vice President. "Largest Bauxite Producing Country 2015 | Statista." Statista. US Geological Survey, n.d. Web. 01 Nov. 2016.

Broehm, Micah. Neodymium and the Global Headphone Market. Rep. no. 51213602. N.p.: n.p., n.d. Print.

"Copper." How Products Are Made. N.p., n.d. Web. 01 Nov. 2016.

"Dynamite." How Products Are Made. N.p., n.d. Web. 02 Nov. 2016.

"Ever Wonder How Aluminum Is Made?" Norsk Hydro. N.p., n.d. Web. 03 Nov. 2016.

"Felt." How Products Are Made. N.p., n.d. Web. 01 Nov. 2016.

Harris, William. "How Aluminum Works." HowStuffWorks Science. HowStuffWorks, n.d. Web. 25 Oct. 2016.

"How Many IPhones Have Been Sold Worldwide?" Lifewire. N.p., n.d. Web. 30 Oct. 2016

"How Neodymium Magnets Are Made." Introduction to Neodymium Magnets. N.p., n.d. Web. 22 Oct. 2016.

Inc, Pro-Edge Consultants. "Dysprosium, REE HandBook." Dysprosium, REE HandBook. N.p., n.d. Web. 22 Oct. 2016.

"IPhone 7 Retail Packaging and What's Inside the Box." Wccftech. N.p., 09 Sept. 2016. Web. 20 Oct. 2016.

"Iron (Fe)." Encyclopedia Britannica Online. Encyclopedia Britannica, n.d. Web. 22 Oct. 2016.

Lister, John. "What Materials Are Headphones Made Of? | Techwalla.com." Techwalla. Demand Media, Inc., n.d. Web. 26 Oct. 2016.

Minerals Education Coalition. "Boron | Minerals Education Coalition." Minerals Education Coalition. N.p., n.d. Web. 02 Nov. 2016.

"Nickel Processing." Encyclopedia Britannica Online. Encyclopedia Britannica, n.d. Web. 21 Oct. 2016.

"Niobium Processing." Encyclopedia Britannica Online. Encyclopedia Britannica, n.d. Web. 28 Oct. 2016.

"Niobium." Great Mining. N.p., n.d. Web. 04 Nov. 2016.

Patel, M. "Sustainability | Paperfoam Biobased Packaging." Paperfoam Biobased Packaging. N.p., n.d. Web. 04 Nov. 2016.

"PLA vs. ABS Plastic - The Pros and Cons - ABS Plastic.eu." ABS Plastic.eu. N.p., 25 Mar. 2015. Web. 01 Nov. 2016.

RecycleNation. "How to Recycle Headphones." RecycleNation. Electronic Recyclers International, n.d. Web. 02 Nov. 2016

"Renew and Recycling." Apple. Apple, n.d. Web. 03 Nov. 2016.

Russell, Sean. "Materials Used in IPod Earphones | Techwalla.com." Techwalla. N.p., n.d. Web. 21 Oct. 2016.

Stone, Maddie. "Researchers Devise a Simple Method For Recycling Rare Earth Magnets." Gizmodo. N.p., 21 June 2015. Web. 10 Nov. 2016

"Wool." How Products Are Made. N.p., n.d. Web. 29 Oct. 2016

worldatlas. "Top Iron Ore Producing Countries In The World." WorldAtlas. N.p., 12 July 2016. Web. 01 Nov. 2016.