Design Life-Cycle

assess.design.(don't)consume

David Mymala

Ashlie Jow, Kayla Fernandes

DES 40A

Professor Cogdell

North Face Borealis Materials

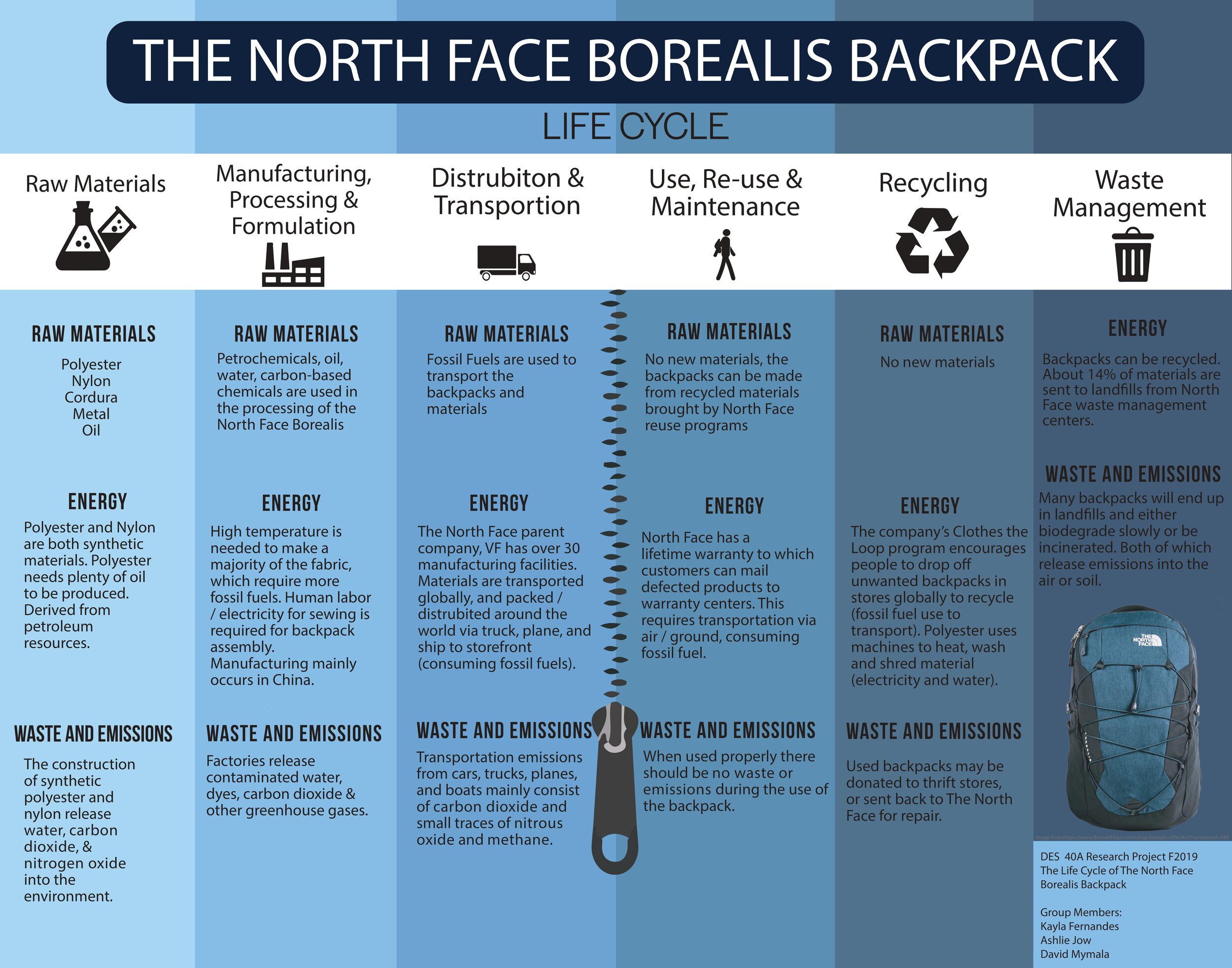

Our group will be researching the North Face Borealis backpack and this paper will be focusing on the materials part of the life cycle. The backpack is made up primarily of nylon and polyester. Nylon is an incredibly resilient material that can restore to its original form after being bent and compressed. (Sim & Prabhu 2017). Polyester is also very resilient and it takes less energy to make polyester than nylon (Karthik et al., 2017). Both of these materials started appearing in products in the 1930s (Edwards, 2016). This combination created a sturdy product that North Face can stand by with their lifetime warranty. Over the years, North Face has increasingly been using more recycled materials like polyester for its products. From using recycled materials, they are also providing a market solution to used water bottles and soda bottles [16]. They aim to create products that can last a lifetime. To better analyze the materials in the backpack, I plan to go into depth in the processes of how each material is made and used over its lifetime. By considering the cradle-to-grave use of recycled materials used in the North Face Borealis backpacks, North Face’s commitment to reducing their carbon footprint is shown.

Northface Borealis is using recycled materials in its product which reduce emissions by acquiring materials and producing material. North Face mentions they are increasing their usage of recycled polyester. Both polyester and nylon are synthetic materials that create waste when produced. Also, both materials are not suited for low impact or natural dyes; there must be a more intensive process for a product made of polyester or nylon to be dyed. This means the process of coloring the dye could have a greater effect on water pollution compared to natural fibers [1, 2]. Polyester is made from petroleum resources which are carbon-intensive and non-biodegradable. Furthermore, over 70 billion barrels of oil are used to make polyester each year. Natural gases and many more chemicals like methanol are part of the process to make polyester or synthetic materials in general (Kalliala et al., 1999). Polyester requires less energy to produce than nylon. The production of polyester uses harmful chemicals including carcinogens and if emitted untreated into the water and air, it can cause significant environmental damage. North Face reduces this impact by using efficient air systems in their facilities to make sure they remove all potent greenhouse gases [15]. Nylon is made from petrochemicals as well and when released into the environment it outputs ash, nitrogen, carbon, and sulfur which contributes to smog and air pollution. Nylon is produced using responding carbon-based chemicals found in coal and petroleum in a high-pressured, warm environment. This process is known as buildup polymerization, and this configures a substantial polymer as a sheet of nylon (Karthik et al., 2017). The byproduct of nylon production is nitrous oxide which contributes to global warming (Edwards, 2016). This is why North Face has stated that they have started working with companies like Bluesign Technologies to combat the environmental damage brought on by chemical processes; they have started using “environmental preferred chemicals” and ensuring their products follow a “restricted substance list” [16]. As for processing these products, North Face facilities are very eco-friendly. Facilities include renewable energy such as wind turbines, solar energy, efficient designing to eliminate all potent greenhouse gases, efficient irrigation systems which reduces the use of outdoor water by 75%, and some recycled materials in their infrastructure [15]. As we can see, the materials used for the backpack are not environmental friendly at all. North Face knows this and tries to reduce the manufacturing process as much as possible. Thus, since some of the material is being recycled, it is shown that they are reducing their waste.

North Face encourages reusing these materials through these programs like their lifetime warranty, North Face, Clothes the Loop, and North Face Renewed. These programs help reduce North Face’s carbon footprint for the Borealis because more materials can be collected to create new backpacks, thus closing the loop. There is also an incentive brought by North Face in donating products which include discounts to North Face products and various other rewards [13]. Creating this loop makes sure the materials for products are in a cycle, which reduces the amount North Face has to get raw material to produce. This includes donating any apparel in which North Face can use the materials in their other products. However, these programs are only useful if a lot of people are using it. There is not a lot of data on this matter. North Face is providing this service, but nylon and polyester generally are usually disposed of in a landfill, this is the weakness of programs such as these, information is not wide spread. Furthermore, nylon is more difficult to recycle than polyester. This is because “nylon is melted at a lower temperature, some kinds of microbes, bacteria or nonrecyclable contaminants can survive” (Karthik et al., 2017). This means that it may not be worth to recycle as the process is more intense when it may be cheaper to make or buy new nylon material. I believe this is why North Face addressed on their website that they are using recycled polyester and never mentioned recycled nylon on their website [16]. Overall, these programs can be good, but there needs to be more research on North Face’s end to showcase that this produces a lot of recyclable material.

The North Face, however, is still not a fully emission-free company. North Face is working towards becoming more environmentally friendly. This means that some of the nylon and polyester that are not recyclable are still being used in the North Face Borealis. Polyester and Nylon both produce a lot of emissions and impact to the environment. Furthermore, a lot of products in the world use nylon and polyester that do not have the same set up in reducing their carbon-emissions like the North Face. However, we do not have any available data on how many recycled materials North Face is using, there is not enough information on the ratio between polyester and nylon in the backpack either. On the North Face Borealis webpage, it states that the product is imported as well [12]. We do not know the conditions of the company that imports the product. North Face acknowledges that there are chemical substances that could be reduced, but it is hard because they feel the customer would not receive the best quality that they could provide [16]. Looking more into the environmental impacts on polyester and nylon it states that nylon and polyester are being produced in more countries where environmental protection laws are weaker, this is something to be suspicious of [1,2]. Overall, North Face does seem to be working towards being an eco-friendly company, but having more details on the route that they take or when it will happen when they become fully eco-friendly will let people become aware.

It is unclear that North Face is moving towards using recycled materials and reducing their carbon footprint. Some signs support North Face being eco-friendly and not being eco-friendly. The facilities that they use are very eco-friendly, while the materials they use are not eco-friendly. However, it is great that they are saying that they are working on this goal of becoming more eco-friendly and not just stating that they are fully eco-friendly. However, North Face should include more specifically how their sustainability process works and how they will be able to achieve their goal of evolving the way their products impact the environment [17]. What North Face is doing is a step in the right direction, they have reduced the energy consumed during manufacturing, and they try to introduce recycling and reuse to the public to start a loop. A suggestion for North Face to further progress their eco-friendly motive is to start making the Borealis using only recycled polyester and other recyclable materials first then from there they can think of further materials that are more eco-friendly to replace it. North Face should use polyester rather than nylon because it is less of an impact on the environment and there is less energy needed to process/produce it. This would be a short term solution. After doing this project, I learned a lot about the industry and the process behind such products like the North Face Borealis. North Face is just one company our group decided to research and I hope many more companies are on board with the idea of becoming eco-friendly. I understand why North Face can not change their materials right away because they have built a brand on quality products with the materials they have been using even though it may not be environmentally friendly. North Face has to keep testing eco-friendly materials to be able to live up to their standard which can be very hard to do. As we are approaching the 2020s, more people are becoming aware of the effects of their favorite products are on the environment.

Bibliography

[1]Edwards, Summer. “The Environmental Impacts of Nylon.” Tortoise & Lady Grey, 17 Oct. 2018, www.tortoiseandladygrey.com/2016/02/01/environmental-impacts-nylon/.

[2]Edwards, Summer. “The Environmental Impacts of Polyester.” Tortoise & Lady Grey, 30 Apr. 2019, www.tortoiseandladygrey.com/2016/08/29/environmental-impacts-polyester/.

[3]Hicks, Andrea L., and Thomas L. Theis. “A Comparative Life Cycle Assessment of Commercially Available Household Silver-Enabled Polyester Textiles.” SpringerLink, Springer Berlin Heidelberg, 7 July 2016, link.springer.com/article/10.1007/s11367-016-1145-2.

[4]Kalliala, Elja M., and Pertti Nousiainen. Life Cycle Assessment ENVIRONMENTAL PROFILE OF COTTON AND POLYESTER-COTTON FABRICS. 1st ed., vol. 1, AUTEX Research Journal, 1999. http://www.autexrj.com/cms/zalaczone_pliki/2b.pdf

[5]Karthik, T., and R. Rathinamoorthy. “Sustainable Synthetic Fibre Production.” Sustainable Fibres and Textiles, Woodhead Publishing, 2 June 2017, www.sciencedirect.com/science/article/pii/B9780081020418000081.

[6]Ploszajski, Anna. "MATERIAL OF THE MONTH: Nylon." Materials World, vol. 22, no. 3, 2014, pp. 58-59. ProQuest, https://search.proquest.com/docview/1514463529?accountid=14505.

[7]Sim, Jaehun, and Vittaldas Prabhu. “The Life Cycle Assessment of Energy and Carbon Emissions on Wool and Nylon Carpets in the United States.” Journal of Cleaner Production, Elsevier, 26 Sept. 2017, www.sciencedirect.com/science/article/pii/S0959652617322059?via%3Dihub.

[8]Smith, G.G., and R.H. Barker. “Life Cycle Analysis of a Polyester Garment.” Resources, Conservation and Recycling, Elsevier, 16 Dec. 1999, www.sciencedirect.com/science/article/pii/092134499500019F.

[9]Telenko, Cassandra, and Carolyn Conner Seepersad . Assessing Energy Requirements and Material Flows of Selective Laser Sintering of Nylon Parts . University of Texas, sffsymposium.engr.utexas.edu/Manuscripts/2010/2010-26-Telenko.pdf.

[10]Telenko, Cassandra, and Carolyn Conner Seepersad . Assessing Energy Requirements and Material Flows of Selective Laser Sintering of Nylon Parts . University of Texas, sffsymposium.engr.utexas.edu/Manuscripts/2010/2010-26-Telenko.pdf.

[11]“Backpacks.” Eco, Eco Cycle, www.ecocycle.org/a-zguide/backpacks.

[12]“Borealis Backpack: Free Shipping: The North Face.” United States, North Face, www.thenorthface.com/shop/borealis-nf0a3kv3#hero=2.

[13]“Clothes the Loop.” The North Face®, www.thenorthface.com/about-us/responsibility/product/clothes-the-loop.html.

[14]“Environmental Impacts.” Green Choices, Green Choices, 19 Apr. 2018, www.greenchoices.org/green-living/clothes/environmental-impacts.

[15]“Facilities.” The North Face®, North Face, www.thenorthface.com/about-us/responsibility/operations/facilities.html.

[16]“Manufacturing.” The North Face®, https://www.thenorthface.com/about-us/responsibility/product/manufacturing.html

[17]“Responsibility.” The North Face®, North Face, www.thenorthface.com/about-us/responsibility.html.

[18]“The North Face Renewed: Refurbished Apparel.” The North Face®, North Face, www.thenorthface.com/about-us/responsibility/product/renewed.html.

Ashlie Jow

Kayla Fernandes, David Mymala

Professor Christina Cogdell

DES 040A

Embodied Energy: North Face Borealis Backpack

NorthFace backpacks are one of the best selling bags in the world for hikers, campers, students and professionals. The Borealis backpack is a convenient bag meant for everyday use, and is built with comfort and functionality in mind. The backpack in particular is unique because it is padded, offers protective sleeves for electronics, and has a bungee cord for external storage, making it versatile for all users. The FlexVent suspension system in the shoulder pads and back paneling provides a support system that makes carrying any load easy. The Borealis backpack was created to answer a call of functionality, comfort and aesthetic. This is what makes the backpack a classic choice for many. North Face as a company strives to use its resources efficiently as a means of reducing environmental impact (“Protect”). In doing so, the company makes its products with the intent of lasting for years to come to reduce the amount of landfill created.. By considering the manufacturing, distribution and end-of-life processes of the North Face Borealis Backpack, we can better understand the company’s mission towards a more conscious use of energy and materials.

NorthFace is owned by VF Corporation, one of the world’s largest apparel companies. Even though NorthFace is an American brand, it has a global supply chain. Resources are found all over the world from Columbia to China (Gintzler). The Borealis Backpack is made of the following imported raw materials: cordura fabric, nylon, polyester, metal and oil (“Borealis”).

Cordura fabric, buckles and thread are made from nylon. Cordura fabric, a particular type of nylon, is produced by the Cordura company. This fabric itself is built to last. It is an exceptionally strong material, certainly great enough to withstand any outdoor activity, or tossing around from everyday use. The manufacturing of Cordura fabric is a secret, thus, for this paper, we will focus on nylon and polyester production. Both are synthetic materials, which need plenty of oil to be produced. This is derived from petroleum.

Nylon is a strong fiber that resists wear and tear and does not shrink or stretch when washed. It is made through a chemical process known as a condensation polymerisation reaction. As a result, polymers for nylon and water are produced (“How is Nylon Made?”). This calls for a need for machinery to drain the water, which consumes electricity. Nylon is made from organic chemicals that are obtained from petroleum refining. Molecules of hexane-1, 6-dicarboxylic acid are combined with 1, 6-diaminohexane in a chemical reaction referred to as condensation polymerization to form a type of nylon popularly known as nylon-6, 6 (“How is Nylon Made?”).

Synthetic fibers like polyester are wrinkle and water resistant, more durable and have a higher color retention. These fibers can also exhibit environmental resistance such as wind and rain. This makes for great outdoor use, and a perfect material for NorthFace to use to make its products (Jr, Esteban Robles). Polyester is a chemical term that can be broken down into “many” and “chemical reactions”. The main ingredient used in the manufacturing of polyester is ethylene, which is also derived from petroleum. Petroleum, like crude oil, is a fossil fuel used in the manufacturing of the Borealis backpack. Petroleum can be found under the earth's surface, thus it is obtained from the ground using a drill rig (National Geographic Society). Drilling uses diesel fuel and electric generators as its primary source of power. The petroleum refining sector is the largest consumer of fuel in the United States (Office of Energy Efficiency & Renewable Energy). After drilling for oil , crude oil is taken into a plant and through the distillation process, ethylene is obtained (Manley 1998). While ethylene is produced by refining petroleum from the distillation of natural gasses and oil, chlorine is also obtained (Jr, Esteban Robles). Both processes used to produce chlorine and the distillation process used to produce ethylene use electricity as a source of power, which can be obtained from wind and coal. Petroleum, like coal and natural gas, is a non-renewable source of energy. It has taken millions of years to form, and once it is extracted and consumed, there is no way for it to be replaced. Polyester fibers and threads are made using a spinning process that allows for the material to blend well.

Zippers are made of a combination of zinc and nylon. Zinc is a natural material. It occurs as carbonate, sulphide or silicate ores. In order for the zinc sulfide to concentrate into zinc oxide, a process known as roasting is required. This is a high temperature process that utilizes hearth roasters. The roasters operate at 690 °C, and the time to compose the concentrated amount of sulfur is depended on the amount needed (United States Environmental Protection Agency).

Much of the manufacturing process in creating the Borealis backpack is dependent on heat, which would consume fossil fuels. However, North Face uses recycled polyester, which has a lower impact on air and water resources than would virgin polyester.

NorthFace’s parent company, VF has over 30 manufacturing facilities globally. Much of the material is imported globally to China for assembly. The Cordura company has a branch in China, which we can assume allows North Face to collect raw materials from there and transport the fabric to manufacturing factories nearby for production, then distributed globally. The NorthFace actually has an environmental compliance policy when it comes to the manufacturing of their products. Their facilities are to meet all applicable laws and employ procedures that minimize air emissions, waste, energy and water use, as well as other significant environmental risks (“Manufacturing”). In order to complete the assembly of a backpack, sewing is necessary, which requires human labor. When the bags are complete, they are packaged and exported globally, meaning by air and ship. In order for the Borealis backpack to get to the storefront, the product must be transported to any facility but truck.

The Borealis backpack uses Cordura fabric, meaning the lifetime of the bag is long. Given that it is built to last, this and other similar synthetic materials have become difficult to recycle. However, since it is such a durable fabric, it has a longer life expectancy which reduces disposal and waste. Cordura is difficult to compose, and the company does not want to be responsible for creating more waste in the environment, so it implemented a lifetime warranty to its customers. Customers can mail their defected backpack to a warranty center where the Borealis backpack can be fixed and renewed. If not, NorthFace will replace the backpack or refund it, free of charge (“Limited Warranty”). Even though a lifetime warranty takes energy consumption from transportation and mailing, the end result extends the lifetime of the backpack in addition to allowing the NorthFace to maintain a recycling program for their returned products.

On average, 10 million tons of textile waste ends up in landfills in the United States, which is enough to fill 250,000 18-wheeler trucks (“Clothes the Loop”). This can be combated with a recycling program. NorthFace has implemented a Clothes the Loop program to recycle their products. The idea is to reduce the environmental impact of their products at all stages of their life cycle. This would also include extending the life of their products to keep it out of landfills. Anyone can drop off their backpack at a NorthFace retail outlet to be recycled. The Clothes the Loop program is active globally which allows for a greater reach in keeping items out of landfills.

Roughly 60% of zinc can be recovered and recycled. The recycling of zinc involves melting or smelting processes. Depending on the form and purity of the metal, it can be melted and cast into new physical forms either for direct reuse or refining (OECD).

The Borealis backpack and all NorthFace products are built to be long lasting, reusable products. NorthFace incorporates recycled materials into their products and take responsibility for their products’ end-of-life by committing to the durability of material. Additionally, the company engages with suppliers in efforts to reduce chemicals, water, energy and waste (“Product”).The backpacks, made of mostly recycled materials, may also be recycled to make new items. Though not biodegradable, the company has found a way to extend the life cycle of its bags.

Energy is consumed in each process of the Borealis backpack life cycle; a majority of which is from the acquisition of raw materials. However NorthFace combats this with a product that lasts years, and implements a program to repair any defective item, extending the lifetime of their bag. During the manufacturing process the only major use of energy is heat and water to wash, treat and prepare fabric. The rest is an assembly line of human labor and transportation for distribution. There are many ways to prolong the life cycle of the Borealis backpack before tossing it in the landfill. So in all, even though the Borealis backpack may consume fossil fuels for manufacturing and distributing, the backpack itself will avoid the landfill for many years to come.

Bibliography

“Borealis Backpack: Free Shipping: The North Face.” United States, https://www.thenorthface.com/shop/borealis-nf0a3kv3.

“Clothes the Loop.” The North Face®, https://www.thenorthface.com/en_ca/about-us/responsibility/product/clothes-the-loop.html

Gintzler, Ariella. “You Can Now See Exactly Where Your North Face Fleece Comes From.” Outside Online, 11 June 2019, https://www.outsideonline.com/2354706/vf-corp-north-face-gear-source.

Jr, Esteban Robles, et al. “How Is Polyester Made? - How Is Polyester Made?” Craftech Industries, 14 Nov. 2019, https://www.craftechind.com/how-is-polyester-made/.

“Limited Warranty/Lifetime Guarantee.” Limited Warranty/Lifetime Guarantee, https://www.thenorthface.com/help/warranty.html

Manley, D B. "Thermodynamically efficient distillation: Ethylene recovery." 1998. Missouri S&T - Missouri University of Science and Technology. 27 11 2016. <http://web.mst.edu/~dbm/papers/ethylene.pdf>.

“Manufacturing.” The North Face®, https://www.thenorthface.com/about-us/responsibility/product/manufacturing.html.

National Geographic Society. “Petroleum.” National Geographic Society, 14 Jan. 2013, https://www.nationalgeographic.org/encyclopedia/petroleum/.

“Nylon - The Science of Synthetic Textiles.” Explain That Stuff, 31 Jan. 2019, https://www.explainthatstuff.com/nylon.html.

OECD. Recycling of Copper, Lead and Zinc Bearing Wastes. Paris: OECD, 1995.

Office of Energy Efficiency & Renewable Energy. U.S. Manufacturing Energy Use and Greenhouse Gas Emissions Analysis. Washington, DC: Department of Energy, 2012. <http://energy.gov/sites/prod/files/2013/11/f4/energy_use_and_loss_and_emissions_petroleum.pdf>.

“Protect.” The North Face®, https://www.thenorthface.com/about-us/responsibility/operations.html.

“Sustainability Is Opportunity For The North Face: An Interview with James Rogers, Director of Sustainability.” CleanTechnica, 27 Aug. 2018, https://cleantechnica.com/2018/08/27/sustainability-is-opportunity-for-the-north-face-an-interview-with-james-rogers-director-of-sustainability/.

U.S. Energy Information Administration. Energy for growing and harvesting crops is a large component of farm operating costs. 17 10 2014. 27 11 2016. <http://www.eia.gov/todayinenergy/detail.php?id=18431>.

U.S. Fuel Consumed at Refineries. 22 6 2016. 27 11 2016. <https://www.eia.gov/dnav/pet/pet_pnp_capfuel_dcu_nus_a.htm>.

United States Environmental Protection Agency. "AP 42, Fifth Edition, Volume I Chapter 12: Metallurgical Industry." 10 1986. United Stated Environmental Protection Agency. 27 11 2016. <https://www3.epa.gov/ttnchie1/ap42/ch12/>.

Kayla Fernandes

DES 40A

Professor Cogdell

4 December 2019

Waste and Emissions from The North Face Backpack

The company, The North Face, creates a variety of products ranging from clothing to outdoor gear and backpacks. This brand has created a lifestyle company that promotes exploration, sustainability and durability. One of the most popular products that can be found around campus and used by college-aged students are backpacks. The North Face backpacks are durable, sturdy, spacious and stylish making them a popular choice. The only real downfall of the backpack is the steep price point, which can be justified with a long-lasting use. We live in a world driven by product consumption and manufacturing and with this comes an environmental responsibility. This paper will follow the construction of The North Face Borealis backpack from the waste and emissions point of view. By considering The North Face Borealis backpack’s cradle-to-grave waste and emissions involved in its material extraction, manufacturing, transportation, and disposal, the company demonstrates some level of environmental consciousness.

From the most basic form, The North Face Borealis backpacks are made of nylon and polyester, as found on the North Face website under materials. For the start of the life cycle and for production to begin, the materials need to be made through material extraction. Nylon is a polymer made completely from petrochemicals (Woodford 2). There is no natural form of nylon in our environment, so plants with carbon-based chemicals such as coal or petroleum need to be used to create the desired chemical (Woodford 3). When making nylon, CO2 is an emission from the coal that is burned. The CO2 is released into the atmosphere becoming a greenhouse gas which is one of the main emissions. The nylon polymer is made when two large molecules react from heating them to 500 degrees Fahrenheit. The molecules combine with pressure when they mix together in a reaction vessel. The reaction often leads to water being a byproduct that must be removed (“How is Nylon Made” 1). The water that is used needs to be disposed of properly or it may contaminate the water supply nearby. The actual nylon itself does not have any compounds that are dangerous to the environment, but the chemical process in the manufacturing of nylon is harmful. Processing nylon in factories releases nitrous oxide into the air, and since there are no uses for this byproduct, it is released in the atmosphere as waste (“Nylon: Background” 3). It is known that nitrous oxide is a destructive chemical that once in the atmosphere can harm the stratospheric ozone and is a powerful greenhouse gas. The thermal processing of nylon can result in human health concerns if factory workers are exposed to fumes or dust. This may lead to irritation in the nose, throat, eyes and irritation of skin (“Nylon: Background” 3). These are some of the health concerns that face factory workers when nylon is produced. It does not explicitly say if The North Face Company actually produces their own nylon or buys it from a distributor once it is in the form usable by the company. Either way, the process must be added into the product life cycle.

The process of making polyester is very similar to nylon. It is a synthetic polyester that is made using chemical reactions that involve coal, petroleum, air and water. In this process, an emission is the CO2 from coal and petroleum. Polyester is created from petroleum and made through a energy-intensive heating process that requires large quantities of water for cooling. The most common chemical reaction takes place at a very high temperature inside a vacuum. This reaction is known as polymerization. Polymer material created during this process is stretched out into long fibers that are five times the original length. The fibers and threads are created during the spinning process and are either in the form of long fibers or spun staples (“How is Polyester Made” 2). Once the fibers are spun, then the product can be used for backpack production. A key waste in this process is the water that needs to be properly disposed of. “Worldwide environmental problems associated with the textile industry are typically those associated with water pollution caused by the discharge of untreated effluent and those because of use of toxic chemicals especially during processing” (Khan and Malik 1). Like the nylon process, if the water is not properly disposed of and managed, it can contaminate the community’s drinking water causing harm to people’s health or flow into rivers and oceans. It is common for factories to be built surrounding lower-income areas; therefore, the water pollution can have a detrimental effect on the lives of those who live nearby (Uren 4). It is not known what other environmental options exist and whether or not they are currently being used. According to the parent company of The North Face, the VF Corporation, released a statement saying they are “committed to sourcing 50 percent recycled nylon and polyester for our products by 2025 (“VF Corporation” 1). This is a good start to reducing some of the byproducts and emissions that come with the production of nylon and polyester, but it is not fully in effect today.

Some of the other smaller materials used in the construction of the backpacks include the zippers, foam for the straps, a few small plastic parts and mesh for the cup holders. Zippers can be made out of stainless steel, zinc, aluminum, or brass. The zippers used on this backpack is not known, but it is made of a strong metal which could be stainless steel. The emissions from making a stainless steel zipper include greenhouse gasses, vapors and gases (Chang 14). There are several raw materials such as coal and iron that are needed to make the zipper which releases emissions and waste. It is important to note that all of these smaller parts will have emissions and waste such as carbon dioxide and scraps. Another component of creating the design of the backpack is dying the fabric to create the colors seen on the Borealis backpacks. This requires a special type of dye to color polyester known as disperse dyes (Uren 3). The dyes are incapable of being dissolved and consist of a complex molecule structure that does not easily decompose (Uren 3). The wastewater from the dying process can cause harm to the environment and is toxic to humans who work around the dyes. Overall, dye workers have higher reports of cancers and lung disease than the normal population (Uren 3).

During the manufacturing process of The North Face backpacks, factories are used to mass produce the backpacks. The North Face Company is owned by VF Corporation, and they have factories in the Middle East, China, Vietnam, Bangladesh, El Salvador, Cambodia, USA and a few other countries (“VF Corporation” 2). The main type of emissions from the manufacturing process are from fossil fuels used to power the machines. The main way that the backpacks are constructed is with sewing machines and human labor. Machines are used to increase the efficiency of cutting all the materials to the correct sizes. I was not able to find any information on what happens to unused or damaged materials left over from the manufacturing process, so I am unsure if it is sent to a landfill or reused in some way. Factories release huge amounts of emissions, so The North Face Company addresses environmental factory concerns in the following statement: “We expect our manufacturing facilities to meet all applicable laws and regulations and to employ procedures that minimize air emissions, waste, energy and water use, and other significant environmental risks” (“Manufacturing” 4). It was discovered that some of the chemicals used during manufacturing to improve the backpack’s performance, such as water, stain, and oil repellency, actually contain perfluorinated compounds (“Manufacturing” 3). In addition, The North Face Company has been working to replace these durable water repellency chemicals with more environmentally preferable options to reduce chemical harm (“Manufacturing” 3). After the backpack is finished being constructed, it is then transported to the sellers and distributors.

Once the two main materials, nylon and polyester, are made, they are transported to the factories that construct the backpacks. Transportation is also required once the backpacks have been assembled at the factories to be distributed around the world to stores and consumers. This may be done by air travel, truck, boat, train or all of the above. With the transportation portion, there are several emissions released into the environment. The main sources of emissions into the atmosphere from transportation include carbon dioxide from combustion of gasoline and small amounts of methane and nitrous oxide (“Sources of Greenhouse Gas Emissions” 2). The North Face Company has been offsetting emissions generated from shipping e-commerce orders to customers since 2010 (“Climate Change” 2).

During the use of The North Face Borealis backpack, there should not be any emissions or waste. If the backpack becomes dirty, the company recommends spot washing it with a damp rag and allowing it to air dry. The North Face Company has taken a recycling approach and has a policy that if the backpack becomes broken or damaged, there is a lifetime warranty to repair or replace the damaged product. However, there are limitations to the warranty such as products only being “warranted to the original owner against manufacturing defects in materials and workmanship for the lifetime of the product” (“Manufacturing” 3). “The company's lifetime warranty on its apparel and outdoor gear has led to more than 80,000 products being repaired and returned to customers annually” (Kaye 3). It is unclear as to how many people actually use this service to extend the life of the backpacks, but this new approach helps eliminate some waste of the product.

Once the consumer uses the backpack to its full lifespan, there are several ways to extend the backpack’s life. One way is to donate a backpack in decent condition to a thrift store. The SAGE Journal states, “Recently another option for post-consumer textile waste recycling has been made available to consumers through retailers” (Domina and Koch 5). There is a program called Clothes the Loop ran by The North Face Company that gathers used clothes and other textiles to donate and help support those in need (“Clothes the Loop” 1). Not enough people participate because, “only about a quarter of the post-consumer textile waste is recycled, mostly by nonprofit organizations and consignment shops” (Domina and Koch 2). If the backpacks are not in great condition, then parts that are still good may be removed and reused, but then the actual backpack is most likely thrown in the trash. Once the backpacks end up in landfills, the materials must break down which is a slow process.

The two main materials from the backpack that must be disposed of are nylon and polyester. Nylon has an extremely slow decay rate and may lead to an increase of nylon in landfills. Nylon can break down when ultraviolet light comes in contact with the material. This can be awful in the degrading process because once the product is combined with other chemicals it may emit harmful chemicals into the soil (“Post-Consumer and Post-Industrial” 2). Another way to dispose of nylon products is to incinerate the backpack, however, this process may lead to harmful outputs in the air depending on the landfill and their processes in disposing of waste. It is challenging to recycle nylon because there are relatively few recycling facilities that accept nylon due to the fact that special technology and equipment must be used (“Post-Consumer and Post-Industrial” 3). The equipment used for recycling nylon releases emissions, but extending the life cycle is a better option than having it biodegrade. Most synthetic textiles are designed not to decompose, so once in the landfill, they release toxic substances into groundwater and surrounding soil (“Nylon: Background” 3). So similar to nylon, polyester can take anywhere from twenty to two hundred years to biodegrade (Uren 3). Polyester can be recycled in two ways, either mechanically or chemically. It can either be melted down and released to make yarns or the polymer is broken down into molecular parts to be reformed into new plastics (“Why Is Recycled Polyester” 3). Recycling can result in water pollution because of the microfibers being shredded and washed. Both of chemical and mechanical processes take time and effort, but will greatly help increase the amount of recycled materials that will not end up in landfills to pollute the environment.

Overall, The North Face Borealis backpack leads the consumer to be concerned with the environment when following the waste and emissions of this product. The production of this product takes energy, resources, and produces emissions as part of its life cycle. The assessment of the backpack is favorable when the product is used by the consumer for its full life span. This Borealis backpack is a sustainable option for consumers. The two main products, nylon and polyester, are used in the construction of the backpack because both are durable and strong materials, but the byproducts can also cause harm to the environment through air and water pollution. There are still several unknowns when looking at the full life cycle of this product. It would be beneficial if the company released more information on the entire life cycle of their products. I believe a greater change in recycling polyester and nylon will greatly reduce the emissions and wastes that this product puts into the environment. The company does have some goals in regards to using more recycled materials and reducing greenhouse emissions, which will help show that they are environmentally conscious. However, it is also evident that there is room for improvement and change.

Bibliography

Akhtar, Sana, et al., “Tracking the Carbon Emissions from Polyester Fibre Processing Industrial

Unit.” ProQuest, 2018, search.proquest.com/openview/abe0bb44a75b258f9cac224bce 167b6f/1?pq-origsite=gscolar&cbl=1606374.

Buhu, Adrian, and Liliana Buhu. “Study on the Technical Woven Used for Manufacturing

Backpacks.” BULETINUL INSTITUTULUI POLITEHNIC DIN IAŞI , LXII, 10 Nov.

2012, www.tex.tuiasi.ro/BIP/Fasc_Tex_%201_4_2012.pdf#pa.

Chang, Claudia. “Zippers - Design Life.” Design Life Cycle, Mar. 2014,

www.designlife-cycle.com/zippers.

Chen, Tsao-Chou, and Cheng-Fang Lin. “Greenhouse Gases Emissions from Waste Management

Practices Using Life Cycle Inventory Model.” Journal of Hazardous Materials, Elsevier, 22 Nov. 2007, www.sciencedirect.com/science/article/pii/S0304389407016342.

“Climate Change.” The North Face®, 2019, www.thenorthface.com/about-us/responsibility/

operations/climate-change.html.

“Clothes the Loop.” The North Face®, www.thenorthface.com/about-us/responsibility/product/

clothes-the-loop.html.

Domina, Tanya, and Kathy Koch. “The Textile Waste Lifecycle - Tanya Domina, Kathy

Koch, 1997.” SAGE Journals, 1 Jan. 1991, journals.sagepub.com/doi/abs/ 10.1177/0887302X9701500204?casa_token=VRVpGBTaS58AAAAA%3AF_fN7ynPPT3Clzc37h0le_CEEYp29fyHs1462ROlKbq8znyR8Mie34q9nm87-RwAizj-eHbincmuw9.

“How Nylon Is Made.” Craftech Industries, 1 Nov. 2019, www.craftechind.com/uses-of-nylon/.

“How Is Polyester Made?” Craftech Industries, 14 Nov. 2019, www.craftechind.com/how-is-

polyester-made/.

Kaye, Leon. “The North Face Sustainability Report: Environment and Efficiency.” Reporting on

the Triple Bottom Line & Sustainable Business News, 29 July 2014, www.triplepundit

.com/story/2014/north-face-sustainability-report-environment-and-efficiency/42101.

Khan, Sana, and Abdul Malik. “Environmental and Health Effects of Textile Industry

Wastewater.” SpringerLink, Springer, Dordrecht, 8 Dec. 2013,

link.springer.com/chapter/10.1007/978-94-007-7890-0_4.

“Manufacturing.” The North Face®, www.thenorthface.com/about-us/responsibility/

product/manufacturing.html.

“Nylon: Background, Dangers, Disposal.” SchoolWorkHelper, 2018, schoolworkhelper.net/

nylon-background-dangers-disposal/.

“Post-Consumer and Post-Industrial Nylon Recycling.” Hazardous Waste Experts, PEGEX, 11

Feb. 2019, www.hazardouswasteexperts.com/post-consumer-and-post-industrial-nylon- recycling/.

“Sources of Greenhouse Gas Emissions.” EPA, Environmental Protection Agency, 13 Sept.

2019, www.epa.gov/ghgemissions/sources-greenhouse-gas-emissions.

Subramanian, P.M. “Plastics Recycling and Waste Management in the US.” Resources,

Conservation and Recycling, Elsevier, 24 Jan. 2000, www.sciencedirect.com /science/article/pii/S092134499900049X.

Uren, Ashlee. “Material Guide: How Sustainable Is Polyester?” Good On You, 17 Sept. 2018,

goodonyou.eco/material-guide-polyester-2/.

“VF Corporation.” VF Corporation, 2 Dec. 2019, www.vfc.com/.

“Why Is Recycled Polyester Considered a Sustainable Textile?” O ECOTEXTILES, 14 July

2009, oecotextiles.wordpress.com/2009/07/14/why-is-recycled-polyester-

considered-a-sustainable-textile/.

Woodford, Chris. “Nylon - The Science of Synthetic Textiles.” Explain That Stuff, 31 Jan. 2019,

www.explainthatstuff.com/nylon.html.