Design Life-Cycle

assess.design.(don't)consume

Lauren Hong

Emily Kang, Hannah Anderson

DES 40A

Professor Cogdell

02 December 2021

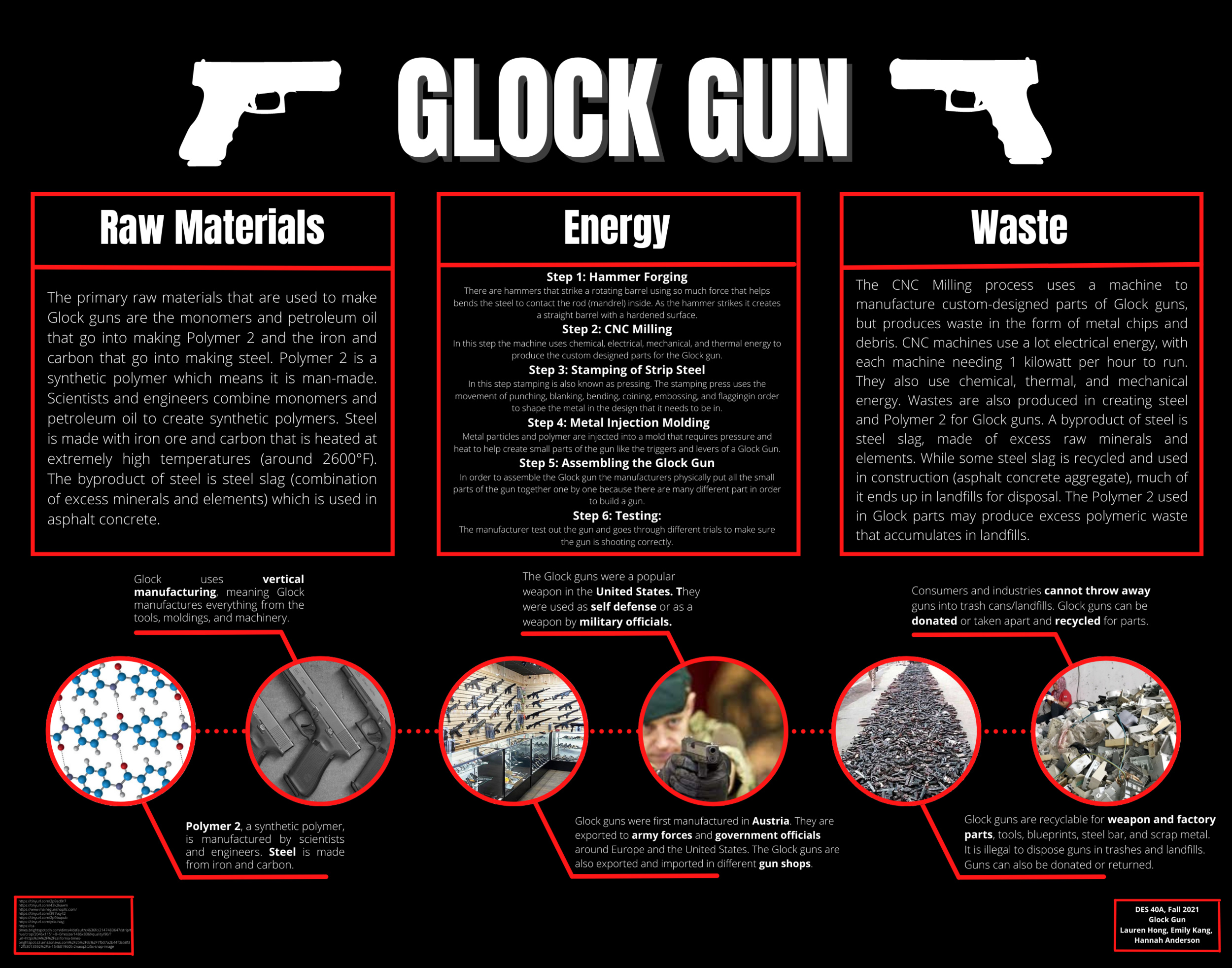

Glock Guns: Materials

The life cycle of Glock guns begins with the process of creating synthetic materials which are utilized by Glock manufacturing companies to mass-produce the guns. From there, they are sent to Glock distributors who provide the public and military services with Glock guns. Eventually, because of the material of the gun, they can be recycled and refurbished to return back to the production phase of the cycle to create more guns. Generally, most guns are made out of similar polymers, plastics, and metals, however, Glock guns are made of a synthetic material that separate them from other types of guns. The material used to produce guns mainly consists of synthetically fabricated plastics and metals. In particular, Glock guns are made of primarily a high-strength nylon-based polymer that is specifically manufactured to benefit the quality of the Glock gun. This polymer, known as Polymer 2, makes the weight of the gun lighter, yet the quality more durable. From the beginning of its creation, the Glock gun has introduced the gun industry with new materials and techniques for better and more efficient gun production and quality.

In 1982, engineer Gaston Glock invented the first Glock handgun which became the first gun to be sold with a polymer frame. In the early 1980s, the Austrian Armed Forces were in search of a new and better pistol gun to be distributed to the new generation of soldiers. Glock collaborated with a group of experts to combine their knowledge in handguns and synthetic materials to create an improved gun. Gaston Glock’s expertise in synthetic polymers is what made the Glock gun what it is today. What makes Glock guns different are their distinct physical characteristics that have given them their popularity throughout history in both military and recreational spaces. Glock is a brand, named after Gaston Glock, that exclusively produces the polymer-framed semi-automatic pistols that we know as Glock guns. Once the Austrian Armed Forces adopted the Glock gun, its popularity grew and other countries began adopting it into their military services. However, recently, Glock guns have expanded from exclusively being a military and police weapon to a popular gun for citizens to purchase. Particularly, the gun’s utility makes it popular. They can carry almost three times the rounds of an average revolver, yet with half the weight of a normal trigger pull. They are also made using a plastic mold instead of steel attachments which contribute to their lightness. However, the polymers that make up the Glock gun are what give the Glock gun its recognizable features. Though the gun does use steel, such as in the slide of the gun, it is largely made of Polymer 2 which was engineered by Gaston Glock specifically for the Glock gun. This is what makes it so durable and resistant to corrosion and extreme temperatures.

Glock guns are also distinguishable because they are made of only 34 parts and mainly two materials. The pistol is separated into five major component groups: the barrel, frame, slide, magazine, and recoil-spring assembly. The barrel is the tubular structure that the bullet goes through when fire. The Glock gun has a particular barrel with polygonal rifling which spins the bullet intensely which result in a more accurate and smooth shot. The gun’s frame is what makes it most identifiably a Glock gun. This is because the polymer frame is what makes it light weight yet resistant to harsh environments. Inside of the frame is the slide which moves back and forth to initiate the process of shooting. The component that holds the bullets is the magazine which has a spring that allows for quick and concise bullet reloading. Lastly, the recoil-spring is what makes the gun safe to use. The recoil-spring absorbs the shock from the gun recoiling which allows the shooter to avoid feeling the full effect of the firing bullet. Some more elements include a trigger bar, trigger spring, slide cover plate, slide stop lever, and a locking block pin. In order for the gun to fire, the trigger bar is guided by the connector to pull the firing pin back. The firing pin is then released forward which then fires the bullet. The ejector then reloads them next bullet to prepare for firing. All of these processes require steel parts which are a vital part of the gun. Many components that are necessary for the gun to fire are made of steel such as the steel trigger bar and ejector, however, the overall body and frame of the gun are made of Polymer 2.

As discussed before, Glock guns are made of Polymer 2, however, the weight of the gun primarily comes from steel. Steel is produced by taking iron ore and carbon. Iron ore is a natural material that is mined from the ground which contributes to the steel’s strength and weight. Iron and carbon undergo a process of extreme heating. They are melted at temperatures of 2600 degrees Farenheit or more then cooled. The steel production process creates a byproduct called steel slag. Steel slag is a combination of minerals such as titanium, ironsand, silica, and elements such as calcium and magnesium. Steel slag is also a useful material that is used by many countries including the United States in the production of asphalt concrete which is used to pave roads. Steel is known to be a heavy yet very efficient and strong material and is used to make many types of guns. However, the heavy weight of the material can make gun use less efficient. That is why the invention of a polymer-based framework changed the gun industry and popularized Glock guns. Polymer 2 was made by Gaston Glock, creator, engineer, and manufacturer of Glock guns. As he was a specialist in synthetic polymers, Polymer 2 is a synthetic polymer which means it is man-made. Synthetic polymers are created by scientists and engineers and are then mass produced in factories. Synthetic polymers are made from a combination of different monomers and petroleum oil that, once combined, can create solid durable materials. Monomers are any molecules that have the capabilities to attach to other molecules which them former larger molecules which are considered polymers. Scientists and engineers must experiment with different monomers to create polymers with different capabilities. Petroleum oil is also utilized in most synthetic polymers. Petroleum oil is a fossil fuel that is commonly known as crude oil. Just like all fossil fuels, petroleum was formed by the fossilization of different marine plants, algae, and bacteria from ancient times. Petroleum has evolved into a mixture of different hydrocarbons which makes it rich in carbon. This is why it is now used to fuel many products. Currently, petroleum oil is most commonly found in gasoline which is used as a common source of energy. In synthetic polymers, specific hydrocarbons of petroleum make the polymers more versatile. They provide the polymers with advantageous qualities such as flexibility, strength, and resistivity. Polymer 2 has a specific group of qualities that make the gun highly resistant to various climatic environments and lubricants. It also boosts the absorption rate of the guns recoil and makes the gun easy to maintain. This has all been proven by the Glock company through a series of extensive testing. In order to test the maximum capabilities of the Glock gun, it was tested in extremely cold and hot temperatures, and in elements such as salt water, mud, and sand. These testings show that Polymer 2 is heavy-duty and resistant. Both Polymer 2 and steel give Glock guns the capability to utilize vertical manufacturing.

Glock manufacturing uses a high level of vertical production to produce a wide variety of products. Vertical manufacturing is when manufacturers take control of different parts of the production process in order to obtain a strategic advantage. Glock utilized this type of vertical integration by producing the tools and machinery needed to make the moldings and other building blocks that make the components of Glock guns. Because Glock guns have a polymer-based frame, they can be created through a process of molding. With the new age of 3D printing, Glock has utilized CAD construction to created molds for their guns. Glock gun production includes a variety of physical processes including hammering, milling, stamping, and winding, all processes which take kinetic energy. Because of vertical manufacturing, Glock has complete control over the production of every component of their guns. This give Glock the power to be the only manufacturer of Glock guns specific polymer-framed pistols. Because Glock guns have become so popularized in military and police use, Glock has undergone certifications in order to guarantee quality assurance. Glock has been certified as claimed by ISO 9001 and ISO 14001. ISO 9001 and ISO 14001 are international standardized rulebooks for quality management and environmental management. Specifically ISO 14001 demonstrates Glock’s attempt to be more sustainable and lessen their carbon impact. Glock’s vertical production and quality control certification reinforces Glock gun reliablity and security.

Through the process of created Glock guns, the invention of Polymer 2 became a revelation for the gun industry not only because of the improved quality of the gun but also because of how it changed gun production. Gaston Glock’s engineering expertise invented a material that brought forth a gun with immensely advantageous qualities, so much so that it became the standardized weapon in military and police forces across the world. The combination of Polymer 2 and steel make Glock guns lighter yet more productive and strong than other guns. The simplicity in the design and the highly desirable characteristics of the gun make it one of the most famous guns in the United States not only for the military but also in private homes. Overall, the innovative materials and production processes used to make Glock guns have allowed Glock to become as successful as it is today.

Bibliography

Davis, Ben. “What Is a Range of a Glock 19?” MVOrganizing, MVOrganizing, 7 Apr. 2021, https://www.mvorganizing.org/what-is-the-range-of-a-glock-19/.

Davis, Ben. “What Material Is a Glock Slide Made Out Of?” MVOrganizing, MVOrganizing, 16 Feb. 2021, https://www.mvorganizing.org/what-material-is-a-glock-slide-made-of/#What_material_is_a_Glock_slide_made_of.

Duvigneau, Stefanie, et al. “Petroleum-Based Polymer.” Petroleum-Based Polymer - an Overview | ScienceDirect Topics, 2021, https://www.sciencedirect.com/topics/engineering/petroleum-based-polymer.

The Editors of Encyclopaedia Britannica. “Monomer.” Encyclopædia Britannica, Encyclopædia Britannica, Inc., 2020, https://www.britannica.com/science/monomer.

“Glock.” Wikipedia, Wikimedia Foundation, 2 Dec. 2021, https://en.wikipedia.org/wiki/Glock#Design_details.

Kinman, Greg. “Glock 19: Parts of the Worlds Most Popular Handgun: Gun Carrier.” American Gun Association, 2015, https://blog.gunassociation.org/glock-19-beginners-guide/.

McCarthy, Erin. “Why the Glock Became America's Handgun.” Popular Mechanics, Popular Mechanics, 12 Feb. 2021, https://www.popularmechanics.com/military/weapons/a7445/why-the-glock-became-americas-handgun/#:~:text=The%20Glock%20is%20literally%20made,not%20cleaned%20properly%20or%20regularly.&text=The%20gun%20is%20always%20on.

Perfection, Glock. “Glock Perfection: Advanced Manufacturing.” GLOCK Perfection | Advanced Manufacturing, Glock Perfection, 2021, https://eu.glock.com/en/explore-glock/advanced-manufacturing.

Perfection, Glock. “GLOCK Technology.” Glock Technology, 2021, https://us.glock.com/en/learn/glock-pistols/technology.

Ritman, Matt. “How a Glock Works .” How a Glock Works, Youtube, 2019, https://www.youtube.com/watch?v=V2RDitgCaD0.

Tylka, Phil, et al. “How to Build a Glock at Home – No Serial Number, No Registration!” Gun University, Gun University, 14 Oct. 2021, https://gununiversity.com/build-glock-home-no-serial-number-no-registration/.

“Steel Slag: The Incredible, Upcycable Byproduct of Steelmaking.” – Official POSCO Newsroom, 21 Jan. 2016, https://newsroom.posco.com/en/steel-slag-the-incredible-upcycable-byproduct-of-steelmaking/.

Webb, Alice Jones. “What Are the Parts of a Handgun? A Guide with Photos.” The Lodge at AmmoToGo.com, 2 July 2019, https://www.ammunitiontogo.com/lodge/parts-of-a-handgun/.

Wenty, Edward F. “Steel.” Encyclopædia Britannica, Encyclopædia Britannica, Inc., 2019, https://www.britannica.com/technology/steel.

Emily Yeh Eun Kang

Lauren Hong, Hannah Anderson

Professor Christina Cogdell

Energy, Materials, and Design Across Time (DES 040A)

02 December 2021

Glock Gun: Energy

The production of Glock Guns begins with the process of creating synthetic materials which are then used by Glock manufacturing companies to mass production. Glock guns were first created by a man named Gaston Glock and were first introduced in 1980 in Austria. Since 1982, they are sent to Glock distributors who provide the public and military services with Glock Guns. Eventually, Glock guns can be recycled and refurbished to create more Glock Gun. This paper discusses the embodied energy required in order to create one gun. In order to construct a Glock gun, there are different energy input that involves the energy input of hammer forging which is very beneficial when making rifle guns in general, CNC milling and turning, stamping of strip steel, metal injection molding, and finally the assembling, disassembling, and recycling process of the Glock gun.

The first step of manufacturing a Glock gun is called hammer forging. This process involves using a machine hammer that strikes a rotating barrel with a lot of force which helps bend the steel so that it can be in contact with a rod called the mandrel, that is inside the barrel. According to the article in New York Times called, Where Guns Go to be Reincarnated, written by Tiffany Hsu, the steel is from melted guns and is put into molten metal so they can create very high-quality metal. Hsu mentions that the gunmetal undergoes thermal and chemical energy and is melted by being heated 3,000 degrees Fahrenheit in order to liquefy them which are then used to produce more Glock guns. According to Kathleen Savage, who has a Ph.D. in biological science and is a member of the National Forensic Science Technology Center, mentions that the rotating barrel requires a lot of force and compression from the hammer and that depends on the rate of the rotation and also the frequency of how much the hammer strikes. Savage points out that as the hammer keeps striking a result of peening happens. According to Savage, peening is when “steel springs away from the mandrel after the force is removed.” As the barrel is constantly hammered it also makes the gun barrel longer, which allows bullets to shoot out straight. When the peening and hammering process ends it creates a smooth and hardened surface for the barrel section of the Glock gun.

The second embodied energy required in order to produce Glock guns is called CNC milling. According to an article named, What Are the Basics of CNC Milling and Turning, written by Amit Shirsat, CNC milling is one of the efficient ways to form metal. Shirsat mentions that CNC milling allows manufacturers to produce custom-designed parts of the gun faster. CNC milling requires the machine to rotate the object on a spindle and the part undergoes a process called subtraction machining, which helps build the shape of the Glock gun. Shirsat includes that as the piece is being made a tool called “rotating multipoint cutting tool”, constantly is rotating around the gun piece until the small parts are in the shape that they are supposed to be in. According to Shirsat the different energy that is required to create the many pieces are chemical, electrical, mechanical, and thermal. The milling is one of the most important processes because it determines how reliable, and the sustainability of the Glock gun will be. Shirsat mentions that there are several finishing touches after a piece undergoes CNC milling. For instance, the manufacturers would use finishing touches by doing anodizing or painting. A CNC milling corporation called Technox provides finishing services so that it will help the metal from oxidizing so it lasts for a long period of time. Especially for guns, it is important that the gun does not oxidize. Coating the metal prevents the gun from a chemical reaction or physical damages.

The third embodied energy for the production of Glock gun is the stamping of strip steel. After parts of the Glock gun are produced through CNC milling, the manufacturers collect more steel in order to create the larger parts of the Glock gun. A corporation that is called ESI Engineering Specialties, provides stamping steel for many companies that require steel or metal to create their product. For Glock guns, more steel is being used to create more parts and also the overall design of the gun. Through the stamping of strip steel, it undergoes the energy of the machine punching, blanking, and bending in order to create the right shape for the Glock gun. The ESI corporation mentions that as the stamping process is happening, there is also heat that is applied to the steel in order to create a more durable gun. After the use of thermal energy on the steel, there is grinding that is involved that helps build a smooth surface for the overall design for parts of the Glock gun. The CNC milling and the process of stamping steel are the two main energies that are used to create the different parts of the Glock gun which are then later sent to manufacturers to assemble the parts of the gun together.

The fourth process that the Glock gun goes through is metal injection molding. According to National Rifle Association (NRA), it mentions that metal injection molding was first developed in the 1980s. The metal injection molding (MIM) was mainly used for very small components of the gun for example the trigger, or levers of the gun. The article, What is Metal Injection Molding, written by Leslie Langnau, mentions that it is very important to have the raw materials prepared for the process of metal injection molding. Langnau mentions the MIM undergoes three processes which are printing, de-binding, and sintering. Printing is the beginning where the raw materials are prepared and then put into the molds and undergoes a lot of mechanical energy like a great amount of force and pressure in order to create good quality material for the product. The second step is the de-binding process, where it undergoes thermal energy, and fuses the mold together and it becomes a metallic part. Finally, the MIM uses the sintering process to make sure there is no breakage and incorporates pressure to make the density up to about 95% or even 99% so it is strong metal or steel. The National Rifle association mentions that MIM requires having the metal particles and polymer binder mixture be injected in a heated mold. As the mold is cooled down then it goes through thermal energy by being put into 2,000 Fahrenheit. There is then a chemical reaction/energy where the metal in the mold starts to fuse together and it creates a very hard material and surface so that the parts are sustainable. As the material is starting fuse it starts to shrink allowing to create a smaller part of a Glock gun.

The Glock guns are mainly made in Austria and the United States and assembled by hand physically with all the parts of the gun that have been made through the machines. A corporation call Glock Inc. is known for their production of many Glock guns and they mention that they make each part of the Glock gun through machines. However, when it comes to finally assemble the gun together the manufacturers do it by hand because they need to test out whether or not the gun was designed correctly, and they have to make sure it does not break. According to an article called, Glock Guns Made in the USA? YES, This is Happening, written by Charlie Gao, mentions that the majority of the Glock guns were manufactured in Austria and then started to grow a lot in the U.S market. They were usually exported from Austria to the United States for military purposes and for a lot of government officials.

When the Glock guns are about to be disassembled there is not a lot of research that conducts what they do with all the leftover Glock guns. There is broader information about how the manufacturers get rid of guns in general, but there was not a lot of information that has been discussed recycling Glock guns. There was an article called, It’s Way Too Hard to Dispose of Unwanted Guns In The U.S, written by Nick Wing, which mentions that there are not many options for people to just throw their guns in landfills instead they donate them or end up reselling them. The Glock gun itself has very good metal and steel and those two materials are considered secondary materials and are made through primary materials. The article above called Where Guns Go to be Reincarnated, written by Tiffany Hsu, mentions that most guns are recycled by using thermal energy to melt the metal or steel down and those materials would not go to waste. Instead of going to waste it would be used to produce more valuable guns and create a brand-new gun. As they reuse the Glock guns it would be also beneficial because usually metal and steel are expensive when making a product, but they would have so much by recycling the guns instead of throwing them to waste. There is not that much information about the recycling of the Glock Gun however, it would recycle because there are several cases in general where manufacturers reuse the old guns again to create newer and higher quality material for future guns.

To conclude, this essay talked about the embodied energy of the production of Glock Guns. There is the chemical, thermal, and mechanical energy that is included in the process of manufacturing different parts of the Glock Gun. The essay also discusses the origin, primary, and secondary energy that are involved. The Glock gun also undergoes a cycle of CNC milling and turning, stamping of strip steel, metal injection molding, and finally the assembling, disassembling, and recycling process of the Glock gun.

Bibliography

Davis, Ben. “What Is the Range of a Glock 19?” MVOrganizing, MVOrganizing, 7 Apr. 2021, https://www.mvorganizing.org/what-is-the-range-of-a-glock-19/.

McNab, Chris. Glock: The World's Handgun. 9781782743026 epub, Amber, 2015, www.amberbooks.co.uk, https://www.amberbooks.co.uk/book/collectors-guides-glock/, Accessed 24 Oct. 2021.

Gao, Charlie. “This Is How the Glock 19 Pistol Changed Everything.” The National Interest, The Center for the National Interest, 10 Dec. 2019, https://nationalinterest.org/blog/buzz/how-glock-19-pistol-changed-everything-103487.

Cleckner, Ryan. “How to Build a Glock at Home – No Serial Number, No Registration!” Gun University, Gun University, 14 Oct. 2021, https://gununiversity.com/build-glock-home- no-serial-number-no-registration/.

“Glock 19: Parts of the World’s Most Popular Handgun: Gun Carrier.” American Gun

Association, https://us.glock.com/en/learn/glock-pistols/technology.

Douglas, Richard. “Glock Model 19 9mm Gen 4 Gun:the Best Compact Pistol in the World?” The National Interest, The Center for the National Interest, 7 Mar. 2020, https://nationalinterest.org/blog/buzz/glock-model-19-9mm-gen-4-gunthe-best-compact-pistol-world-130222.

Rutledge, Andy. “Shooting Review: The Glock 19 Gen 5.” Eagle Gun Range Inc., Eagle Gun Range Inc., 9 Oct. 2017, https://www.eaglegunrangetx.com/shooting-review-the-glock- 19-gen-5/.

Editor, The. “Metal Treatments: Ferritic Nitrocarburizing/Melonite/Tenifer.” Metal Treatments: Ferritic Nitrocarburizing/Melonite/Tenifer, 1 Jan. 1970, http://firearmshistory.blogspot.com/2010/08/metal-treatments-ferritic.html.

E, Aaron. “U.S. Navy SEALS Switch to Glock 19!” Blue Sheepdog, 25 Aug. 2019, https://www.bluesheepdog.com/2016/01/06/glocks-n-seals/.

Cleckner, Ryan. “How to Build a Glock at Home – No Serial Number, No Registration!” Gun University, Gun University, 14 Oct. 2021, https://gununiversity.com/build-glock-home-no-serial-number-no-registration/.

Hsu, Tiffany, and Jenn Ackerman. “Where Guns Go to Be Reincarnated.” The New York Times, The New York Times, 24 July 2018, https://www.nytimes.com/2018/07/24/business/gun-buyback-recycling-melt.html.

Wing, Nick. “It's Way Too Hard to Dispose of Unwanted Guns in the U.S.” HuffPost, HuffPost, 12 Oct. 2018, https://www.huffpost.com/entry/gun-disposal-buyback-us_n_5bb64d69e4b028e1fe3bd152.

Glock Gun Wastes & Emissions from ProductionProcess

By: Hannah Anderson, (Lauren Hong, Emily Kang)

Introduction

Glock is a well-known manufacturer of firearms, known for their use of advanced materials and precision manufacturing techniques. However, the production of firearms, including Glock guns, also has environmental impacts in terms of waste and emissions. This research paper aims to explore the environmental impacts of Glock gun production, with a focus on the waste and emissions that it produces. This paper will also focus on wastes and emissions for firearms as a whole, as much of the Glock production is not disclosed with the public.

The production of Glock guns begins with the process of creating synthetic materials which are used by Glock manufacturing companies for mass production. From there, they are sent to Glock distributors who provide the public and military services with Glock guns. Eventually, Glock guns can be recycled and refurbished to create more Glock guns.

Background

The primary raw materials that are used to make Glock guns are the monomers and petroleum oil that go into making Polymer 2 (or polyethylene terephthalate, PET) and the iron and carbon that go into making steel. PET is a synthetic polymer which means it is man-made. Scientists and engineers combine monomers and petroleum oil to create synthetic polymers. Steel is made with iron ore and carbon that is heated at extremely high temperatures (around 2600°F). Polymer is a type of plastic known for its strength, durability, and resistance to impact and extreme temperatures. Other materials used in the production process include various alloys for the barrel and slide, as well as various small components such as springs and screws.

The production of Glock guns requires significant energy inputs in the form of electricity, fuel, and other resources. This energy is used for activities such as heating, cooling, and powering the machinery used in the production process. Additionally, the distribution, disassembly, and recycling of Glock guns also requires significant energy inputs. There are 6 steps in the production process and its energy usage. These include hammer forging to create a straight barrel, CNC milling to produce custom designed parts, stamping (or pressing) of strip steel to shape metal into its design, metal injection of particles and polymer into a mold parts such as triggers, assembly of the Glock gun, and finally the testing of the gun.

Off-Gassing

The production of Glock guns generates a variety of waste materials, including polymer scraps and steel scraps. These waste materials can have significant negative environmental impacts if not properly managed. To address this issue, Glock has implemented a recycling program for polymer scraps, which allows them to recycle and reuse these materials in the production process.

Off-gassing plays a significant role in the wastes and byproducts of Glock - specifically steel and PET - production. Off-gassing refers to the release of gasses from the metal or other materials being heated. When steel is produced, off-gassing can include the release of carbon dioxide, carbon monoxide, nitrogen oxide, sulfur dioxide and hydrocarbons. Nitrogen (NOx) oxide is a harmful air pollutant that can contribute to the formation of smog and acid rain. NOx emissions are often regulated by environmental agencies due to their negative impacts on human health and the environment. Sulfur dioxide (SO2) is another air pollutant that can contribute to acid rain and respiratory problems. SO2 emissions may also be regulated by environmental agencies. Hydrocarbons (HC) are organic compounds that can contribute to the reformation of ground-level ozone and smog. Emissions may be regulated as well. Carbon monoxide (CO) is a toxic gas that can cause health problems such as headaches, dizziness, and nausea. CO emissions may also be regulated due to their negative impacts on air quality and human health.

PET is typically produced through a process called polymerization, which involves heating and combining various chemicals to create the plastic. Off-gassing during PET production can include the release of acetaldehyde, methanol, carbon dioxide, and volatile organic compounds. Acetaldehyde is a toxic and potentially carcinogenic gas that can be released during the polymerization process used to produce PET. Acetaldehyde (CH3CHO) is used as a catalyst during the reaction and can be released as a byproduct. It is also a key component of the final PET product. Methanol (CH3OH) is another byproduct of the polymerization process to produce PET. It is a flammable liquid and can be hazardous to human health if it is ingested, inhaled, or absorbed through the skin. Carbon dioxide (CO2) is a greenhouse gas that is released during the polymerization process, as well as during the subsequent processing and handling of PET. CO2 emissions contribute to global climate change. This is also a byproduct of steel production as mentioned previously. Volatile organic compounds (VOCs) are organic chemicals that can be released during the manufacturing process or during the use and disposal of PET products. VOCs can contribute to the formation of ground-level ozone and smog, and they may have negative impacts on human health.

Environmental Impact

The primary raw materials - steel and PET - are sourced from suppliers and require extraction and processing, such as mining for iron ore used in steel production. This phase has significant environmental impacts, such as deforestation and habitat destruction from mining, as well as emissions from processing and transportation of raw materials. In general, industrial processes for steel production and PET manufacturing can release a variety of pollutants into water sources. These include metals such as iron, chromium, and nickel, organic compounds such as benzene and toluene, acids and alkalis used in industrial processes, and coolant and lubricant fluids used in manufacturing equipment. These pollutants can harm aquatic life and ecosystems, as well as impact the quality and safety of drinking water supplies.

Iron mining can have significant impacts on the environment as well. In order to access iron ore deposits, forests are often cleared, which can lead to habitat destruction, soil erosion and loss of biodiversity. Mining operations can result in soil degradation and loss of fertility, making it difficult for vegetation to grow and impacting the ability of the land to support wildlife. Iron mining can release pollutants into the water sources, such as acids and heavy metals, which harm aquatic life and make water unsafe for human consumption. Iron mining can release airborne pollutants, such as particulate matter and sulfur dioxide, which contribute to air pollution and negatively impact human health. Finally, mining and processing iron ore requires significant amounts of energy, which contributes to greenhouse gas emissions and climate change.

When the raw materials have been sourced in the production process, they are molded and shaped into the various components that make up a Glock gun. This process may involve the use of injection molding machines and other machinery - known to be used for gun production but not guaranteed to be used by Glock from online resources - which can consume energy and release pollutants into the air and water. Once the gun is assembled, it goes through a finishing process, which includes cleaning and polishing the surfaces, and checking for quality. This phase may involve the use of certain chemicals which can release pollutants into the air and water.

After the guns have been produced, they are then distributed to dealers and retailers. This phase may involve significant transportation emissions, depending on the distances and methods of transportation used. Types of transportation used throughout the manufacturing of the Glock gun and its materials include trucks, ships, trains, and planes. The environmental impacts of transportation are well-documented, and include air pollution, greenhouse gas emissions, and water pollution. Truck and ship emissions include nitrogen oxides, sulfur oxides, and particulate matter, which contribute to smog and acid rain, and have negative impacts on human health and the environment. Additionally, shipping and transportation can result in oil spills, which have devastating impacts on marine ecosystems.

The exact amount of waste and pollution caused by transportation throughout the phases of Glock manufacturing are difficult to quantify, as it depends on a range of factors such as distance traveled, mode of transportation, and fuel type. However, it is clear that transportation has a significant environmental impact. The Glock company states that it has implemented various measures to minimize these impacts, such as implementing strict waste management protocols and using energy efficient machinery that aim to reduce emissions and pollutants to the environment.

Energy

During the design and prototyping phase, Glock designers and engineers create and test new designs for the guns. This phase can involve the use of computer-aided design (CAD) software and 3D printing technology. This often generates waste such as failed prototypes or discarded designs. Energy output from the use of computer software and 3D printing technology is important to consider as well.

Landfill and Recycling

Glock guns are recyclable for weapon factory parts, tools, blueprints, steel bars, and scrap metal. However, it is illegal to dispose of guns in trash and landfills. This means consumers and industries cannot simply throw guns into the trash when disposing of them. Alternatively, Glock guns can be donated, returned, or taken apart and recycled for parts. After the various components have been molded and shaped, they are then assembled into a complete Glock gun. This process generates waste such as scraps and offcuts from the cutting and shaping of materials.

The CNC Milling process uses a machine to manufacture custom designed parts of Glock guns, but produces waste in the form of metal chips and debris. Steel slag, the byproduct of steel, is made of excess raw minerals and elements. While some steel slag is recycled and used in construction (such as asphalt concrete aggregate), much of it ends up in landfills for disposal. The Polymer 2 used in Glock parts may produce excess polymeric waste that accumulates in landfills. Glock states to have also implemented a closed-loop production process, which allows them to recycle and reuse materials such as steel and alloys. This reduces the amount of waste generated as well as the need to extract new raw materials, thus claiming to reduce the environmental impact of their production process.

Conclusion

The production of firearms have significant environmental impacts in terms of waste and emissions. The research process and discovery of exact wastes and emissions generated during the production of Glock guns has been difficult, as information on this topic is oftentimes vague to the Glock process specifically, and is likely proprietary and closely guarded by the company. Research shows, however, that the Glock company has implemented a number of initiatives to minimize the impacts and promote sustainability in the production process. The use of advanced materials, such as polymer, and precision manufacturing techniques, as well as a recycling program, closed-loop production process, and strict waste management protocols and energy-efficient machinery, all contribute to reducing the environmental impact of their production process.

Bibliography

Chevron Phillips Chemical Company. "High Density Polyethylene (HDPE) Production."

Chevron Phillips Chemical Company, 2021,

https://www.cpchem.com/bl/specchem/en-us/Documents/HDPE%20-%20Production.pdf.

Davis, Ben. “Home.” MVOrganizing, 16 Feb. 2021,

https://www.mvorganizing.org/what-material-is-a-glock-slide-made-of/#:~:text=Glock%2

0uses%20at%20least%20AFAIK,uses%20stainless%20for%20these%20parts.

Environmental Protection Agency. "Iron Mining: An Issue of Environmental Justice." EPA,

2008, https://www.epa.gov/sites/default/files/2016-09/documents/ironmining.pdf.

“General Overview of the Glock.” The Glock Papers -- General Overview of the Glock,

http://www.f-r-i.com/glock/misc/overview.htm.

“Glock Perfection: Advanced Manufacturing.” GLOCK Perfection | Advanced Manufacturing,

https://eu.glock.com/en/explore-glock/advanced-manufacturing.

Greenpeace International. "The Hidden Cost of Mining: Human and Environmental Impact of

Rare Earths." Greenpeace International, 2020,.

https://www.greenpeace.org/international/story/24471/the-hidden-cost-of-mining-humanand-

environmental-impact-of-rare-earths/.

International Iron and Steel Institute. "Steel's Contribution to a Low Carbon Future and Climate

Resilient Societies." World Steel Association, 2019.

https://www.worldsteel.org/media-centre/resources/publications/steel-s-contribution-to-alow-

carbon-future-and-climate-resilient-societies.html.

International Maritime Organization. "Air Pollution from Ships." IMO, 2022,

https://www.imo.org/en/OurWork/Environment/PollutionPrevention/AirPollution/Pages/

Air-pollution-from-ships.aspx.

Kocak, M., Topkaya, Y. A., & Karakas, M. S. "Environmental impact of steel production: An

energy efficiency approach." International Journal of Energy Research, vol. 38, no. 5,

2014, pp. 571-581, doi: 10.1002/er.3042.

Kusch, P., Eikmeier, J., and Ebeling, J. "Polyethylene." Ullmann's Encyclopedia of Industrial

Chemistry, Wiley-VCH, 2016, pp. 1-61.

Petrochemicals Europe. "PET Resin Manufacturing." Petrochemicals Europe, 2019,

https://www.petrochemistry.eu/pet-resin-manufacturing/.

Smith, Aaron. “Copper Is the New Gold for U.S. Ammo Makers and the Chinese Companies

They're Competing with for Scarce Supplies.” Forbes, Forbes Magazine, 10 June 2021,

https://www.forbes.com/sites/aaronsmith/2021/06/10/copper-is-the-new-gold-for-us-amm

o-makers-and-their-chinese-competitors/?sh=3b2c06079168.

“Stainless Steel and the Environment.” SASSDA, 4 Feb. 2021,

https://sassda.co.za/about-stainless/stainless-steel-and-the-environment/.

Sustainability of Stainless Steels - IMOA.

https://www.imoa.info/download_files/stainless-steel/issf/educational/Module_11_Sustai

nability_en.pdf?m=1592476644&.

United Nations Environment Programme. "Water Pollution." UNEP, 2021,

https://www.unep.org/resources/factsheet/water-pollution.

United Nations Framework Convention on Climate Change. "Transport." UNFCCC, 2022,

https://unfccc.int/topics/transport.

United States Environmental Protection Agency. "Transportation and Air Quality." EPA, 2022,

https://www.epa.gov/transportation-air-pollution-and-climate-change/transportation-andair-

quality.

United States Geological Survey. "Iron and Steel Production in Birmingham, Alabama." USGS,

2019,

https://www.usgs.gov/special-topic/water-science-school/science/iron-and-steel-productio

n-birmingham-alabama?qt-science_center_objects=0#qt-science_center_objects.

U.S. Environmental Protection Agency. "Iron and Steel Production: Air Pollution Control

Technology Fact Sheet." EPA, 2008, https://www3.epa.gov/ttncatc1/dir1/fironstk.pdf.

“Which Material Is Used to Manufacturing of Rifle ... - Quora.” Quora,

https://www.quora.com/Which-material-is-used-to-manufacturing-of-rifle-barrel-and-wh

y.

(https://www.quora.com/Which-material-is-used-to-make-a-gun)

World Wildlife Fund. "Iron Mining: An Issue of Environmental Justice." WWF, 2012,

https://www.worldwildlife.org/industries/iron-mining.

Yablon, Alex, The Trace., et al. “Outdoor Gun Ranges Produce 80,000 Tons of Toxic Pollution a

Year.” The Trace, 23 Sept. 2020,

https://www.thetrace.org/2016/04/gun-range-toxic-lead-pollution/.