Design Life-Cycle

assess.design.(don't)consume

Gian Ayson

Sean Batoon, Nia Heydarfadi

DES 40A

Professor Codgell

Yeezy Foam Runners: Raw Materials

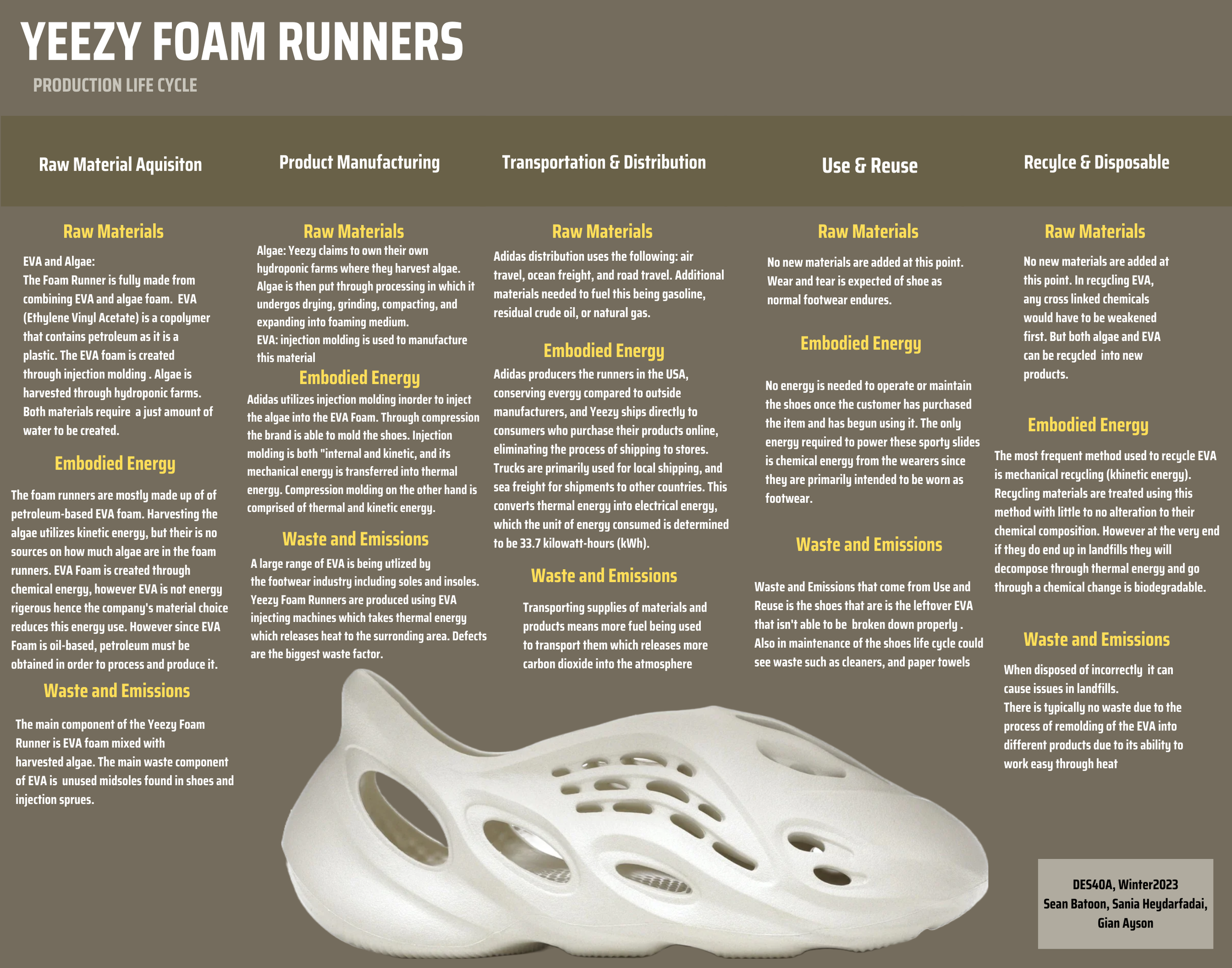

Yeezy is a growing brand in the footwear industry, primarily designed by rapper, Kanye West. With the popularity of the brand, the shoe has continued to grow in demand under the multinational company, Adidas. In 2020, artist Kanye West debuted the Foam Runner shoe that continues in popularity throughout the sneaker industry. The focus of this shoe was to create an environmentally friendly substitute in footwear through the use of more sustainable resources. With the amount of consumption through fashion industries today, knowing whether or not a product purchased contains eco-friendly materials holds great importance. The question is: What materials does Yeezy use in their Foam Runners, and how are these materials implemented in the manufacturing process and waste? Although Yeezy states its efforts in continuing to be environmentally friendly, what and how all raw materials are implemented, beginning to end, is not publicly stated. To further assess the validity of Adidas' previous pledge of being eco-friendly, we look into all raw materials used, both primary and secondary. The Yeezy Foam Runner is solely made from a mix of EVA and algae foam, molded into the product we see today.

EVA foam is a popular secondary material used in the footwear industry, usually used in the sole of the shoe for comfort. The Foam Runner utilizes the foam to form the whole structure of the shoe, not using it in just the soles. EVA is a copolymer; “a thermoplastic elastomer (rubber) characterized by both rigidity and flexibility, as respectively provided by the thermoplastic (low-density polyethylene) and elastomeric (vinyl acetate) segments, which in differing proportions affect the polymer's properties” [11]. The flexibility of this material allows the foam runner to mold into the unique shape. Additionally, it is a versatile, soft, rubbery copolyester, accepting color easily; factors that are ideal for footwear. EVA can be injected into molds, extruded, blow molded, and thermoformed. Yeezy has mentioned the use of molds to create this shape, which we can assume follows one of these techniques since we do not have a direct source of how they are manufactured [11]. Adidas has previously used polyurethane in products such as Adidas slides, which is potentially another material used in Yeezy’s, paired with this EVA foam. Polyurethane can be cross linked with EVA, if this is the case with the Yeezy foam runner, additional raw materials that would be considered are, isocyanates, polyols, hydroxybenzotriazole, monomeric and polymeric hindered phenols, all used in polyethylene [13].

The other major material that is publicly available about foam runners is algae, which combines with the EVA. Algae offers a more environmentally friendly alternative in materials as it reduces the amount of phosphorus and ammonia in waste water industrially and agriculturally [6]. Yeezy claims to have their own farms for harvesting this algae, harvesting it through hydroponics, which is a process that grows plants without any soil. Hydroponics is a more sustainable alternative as it reduces water consumption while still providing all the nutrients needed for the algae to grow[8]. Algae combined with the EVA allows for improvement in output qualities, but is not biodegradable. It is implied that algae itself is sustainable, but since technology of the foam includes a mix of EVA in the algae foam, that the result is less ideal as the best alternative [7]. On the contrary, because Yeezy only discloses having a hydroponic farm for harvesting this material, the ethics of it can only be assumed.Algae is known to use up oxygen from the water, in turn affecting aquatic life negatively. If the farming of algae is genetically modified in any way, this could feed the problem of fast spreading algae, causing more harm to the environment than good [7]. These are the general aspects of the two main materials of foam runners, now how are they used in the manufacturing process of the shoe itself?

As previously mentioned, Yeezy uses molds of this foam to produce the foam runner. How do they do this? An injection method can be assumed that allows for the materials to be manipulated into the final product. EVA is a copolymer, the most common technique in manufacturing for plastic is polymer injection molding. This process uses hydraulic pumps, hybrids (hydraulic with another mechanism to help the hydraulic system), and electric (servo motors)[15].This process requires an abundance of electrical consumption. EVA foam being a commonly used material in the footwear industry, it is possible that Yeezy has a distributor for this material instead of producing it themselves. Although this is possible, it seems to be unlikely as Kanye West has previously announced a want for the company to be, “seed to sole,” meaning an agenda is to be met to cultivate all their own materials, carrying out the product through their own. In regards to the harvesting of algae, its implementation into EVA foam is simple. Again, because Yeezy releases little information of their processing with raw materials, we can assume that the process follows the manufacturing steps another algae foam based company, Bloom Foam, uses in their footwear. This being the following steps: drying the algae, grinding it into powder, compacting it, and lastly, expanding it with foaming agents [14]. At this point in the process, it would be combined with EVA, creating the overall material for the foam runner.

As for the transportation of this product, we can look into the typical cycle of distribution that the brand Adidas follows for their products. Most factories can be found in Asia, with consumers all over the world. Their general path of transportation starts with air travel, followed by ocean freight, and finally road transportation. Adidas is moving towards minimizing air travel as it results in high carbon emissions [13]. Although Adidas works towards decreasing their contribution to global warming through air travel, the alternatives still have negative impacts on the environment. Gasoline is used for road transportation, which is the most common fuel in the United States. The energy content of this is estimated to be 58% of total transportation energy in the country. Ships, on the other hand, typically use residual crude oil or natural gas[15].

The use and reuse of the materials of the foam runners allows the assumption to be made that the shoe is a sustainable product. EVA in footwear is good for footwear as it can endure a lot of wear and tear.This factor allows the foam runner to presumably have a long life cycle before being completely used, since the shoe is not made of many other materials. The con of the EVA foam is its lack of resistance to hot temperatures, meaning although the material can sustain that wear and tear, under certain conditions, it can shorten its use greatly. We can also look into the reuse of both materials. EVA waste specifically has many uses, mainly in composites and concrete. Specific, low-density open-cell EVA foam with low tortuosity have shown potential for being able to be problem solvers in oil spills[3]. It should be noted that EVA is difficult to recycle into other uses like these when the foam is crosslinked; polymer material would need to be weakened first. Algae also can be used for other uses in its raw form, a common use for this is biofuel. It has properties that allow for energy production, wastewater treatment, and carbon dioxide emission [5]. If we, again, base algae use off of Bloom Foam, we know that it is not biodegradable, so reuse for algae is shown to be nonexistent when not in its original form. Other than foam runners having many properties that limit their reuse capacities, the shoe itself is in high demand. We can assume that the longevity of the shoe increases through consumerism if anything. The brand itself holds a lot of popularity, therefore the reuse of the shoe would go to a second market where another person could purchase a used shoe, continuing in this cycle. This in exchange would help keep the shoe from landfills and cause negative effects on the environment to be withheld longer.

Both materials used in foam runners are comparatively more environmentally friendly than most. EVA itself is said to be able to be reused 50 times[3]. Other things that EVA can be recycled into are: ecological concrete, sugar cane bagasse, and as a filling in natural rubbers. It is stated that EVA is overall recyclable although the low melting temperature reduces its sustainability[11]. A con of EVA foam is that it contains petroleum which is a very harmful emission. Algae on the other hand, is generally recyclable.

Although Yeezy attempts to continue in being environmentally friendly and sustainable, the materials used still have factors that cause harm to the environment either directly from the material or harmful depending on how the material is used. Because the process of the foam runner isn’t open to the public, it is difficult to determine if the shoe follows Adidas' pledge to being environmentally friendly. It is clear that the materials used, EVA and algae foam, are the better alternatives in terms of footwear as they use less energy and less emissions than other plastics used in shoes. If Yeezy also cultivates all their own materials, overall the product is environmentally friendly.

Bibliography

[1]“Cross-Linked Polyethylene Foam.” Worldwide Foam - Leading Closed Cell Foam Manufacturer,18 Nov. 2022, Database Material Connexion. https://worldwidefoam.com/cross-linked-polyethylene-foam/.

[2]Rosa, Vanessa Bionda. Zattera, Ademir Jose. Poletto, Matheus. “Evaluation of Different Mechanical Recycling Methods of EVA Foam Waste.” Journal of Elastomers & Plastics.Vol.53, Issue 7, 08 Feb. 2021, https://doi.org/10.1177/0095244321990

[3]Paiva Junior, Cristiano Zenaide. Peruchi, Rogerio Santana. Fim, Fabiana de Caralho. Soares, Williane de Oliveira Silva. Da Silva, Lucineide Balbino. “Performance of Ethylene Vinyl Acetate Waste (EVA-w) when Incorporated into Expanded EVA Foam for Footwear.” Journal of Cleaner Production, Vol.317, No.128352, 1 Oct. 2021, Science Direct. https://doi.org/10.1016/j.jclepro.2021.128352

[4]Lopez-Gonzalez, E., Saiz-Arroyo, C. & Rodriguez-Perez, M.A. Low-density open-cell flexible polyolefin foams as efficient materials for oil absorption: influence of tortuosity on oil absorption. Int. J. Environ. Sci. Technol. 17, 1663–1674 (2020). https://doi.org/10.1007/s13762-019-02576-0

[5]Abdul Ahad Khan, Jawad Gul, Salman Raza Naqvi, Imtiaz Ali, Wasif Farooq, Rabia Liaqat, Hamad AlMohamadi, Libor Štěpanec, Dagmar Juchelková, “Recent progress in microalgae-derived biochar for the treatment of textile industry wastewater.”Chemosphere, Vol.306, Nov. 2022, Science Direct. https://doi.org/10.1016/j.chemosphere.2022.135565.

[6] Rashmi. “ Biomass- Introducing Algae Foam in Shoes.” 23 Oct. 2020. Textile Value Chain. https://textilevaluechain.in/in-depth-analysis/articles/textile-articles/algae-based-foam/

[7]Vankar, Padma S. “ An Assessment and Characterization for Biosorption Efficiency of Natural Dye Waste.” Journal of Cleaner Production. Vol. 60, PP. 65-701, Dec. 2013. Science Direct. https://doi.org/10.1016/j.jclepro.2011.09.021

[8]Premanandh, Jagadeesan. “Factors Affecting Food Security and Contribution of Modern Technologies in Food Sustainability.” Journal of the Science of Food and Agriculture, Vol.91, Issue 15, pp. 2702-271417, Oct. 2011. Wiley Online Library. https://doi.org/10.1002/jsfa.4666

[9]Jeng,Yi-Ren.Liu, De-Shin.Yau, Hong-Tzong. “Designing Experimental Methods to Predict the Expansion Ratio of EVA Foam Material and Using Finite Element Simulation to Estimate the Shoe Expansion Shape.” Materials Transactions, Vol53. No.9, pp 1658-1688. 2012. https://doi.org/10.2320/matertrans.M2012178

[10]Show, Kuan-Yeow. Lee Duu-Jong. Mujumdar, Arun S. Mujumdar. “ Advances and Challenges on Algae Harvesting and Drying.” An International Journal, Vol.33, Issue4,pp. 386-394, 08 Dec. 2014. https://doi.org/10.1080/07373937.2014.948554

[11]Lefteri, Chris. Materials for Design, Laurence King Publishing, 2014. ProQuest Ebook Central, https://ebookcentral.proquest.com/lib/ucdavis/detail.action?docID=1876185.

[12]”Polyurethane.” How Products Are Made. Vol.6. http://www.madehow.com/Volume-6/Polyurethane.html

[13] “Transportation.” Adidas Commodity Chain.https://adidasshoescommoditychain.wordpress.com/transportation/

[14]Elduque, Ana. Elduque, Daniel. Pina, Carmelo. Claveria, Isabel. Javierre, Carlos. “Electricity Consumption Estimation of the Polymer Material Injection-Molding Manufacturing Process: Empirical Model Application.” MDPI. Vol.11, Issue 9. 2018. https://doi.org/10.3390/ma11091740 \

[15]”Use of Energy Explained: Energy use of Transportation.” EIA.https://www.eia.gov/energyexplained/use-of-energy/transportation.php

Sania Heydarfadai

Sean Vincent Batoon, Gian Ayson

DES 40A - WQ 2023

Professor Cogdell

Yeezy Foam Runners: Embodied Energy

As the demand for sustainable clothing has increase among Gen-Z, creators like Kanye West have created eco friendly shoes that supposedly supply that demand. Addidas and Kanye West paired up together to create the Yeezy Foam Runners. Yeezy made the decision to use algae-based foam in their products to address the sustainability issues related to the manufacture of foam products. This program is a part of a larger industry effort to replace foam, one of the main components used to make sneakers, with more environmentally friendly materials. However what sets these slides apart from the competition is the process that goes behind creating them. From harvesting algae and combining it with mostly and petroleum-based ethylene-vinyl acetate, Adidas has taken measures to innovate their manufacturing process when it comes to these slides in order to increase their energy efficiency.

Adidas' manages their supply chain risk when developing their brand and products, as they are "socially and environmentally responsible" for everything they do and produce, in order to “limit any negative effects on workers or the environment.” [1]. Considering this, the clothing company invests thousands of dollars year to minimize energy waste and effectively utilize its resources in order to produce and deliver the finest possible product to its clients. Adidas follows the same policy with its Yeezy Foam Runners. The international company looks for sustainable solutions to reduce the amount of embodied energy used during every stage of production, from purchasing and transporting raw materials to producing and recycling its finished goods. Hence, the organization must adhere to safety standards when developing manufacturing methods.

Algae is one of the raw ingredients that goes into creating the foam runners, and although harvesting them helps clean up the rivers of any detrimental growth, the shoes are “still heavily composed of petroleum-based EVA foam” [2]. Harvesting the algae utilizes kinetic energy, but because their is no sources on how much algae are in the foam runners it is not possible to estimate just how much kinetic energy is being used during production. However we can assume it’s very limited due to the foam runners being composed of mainly petroleum-based EVA foam. EVA Foam is created through chemical energy, due to it’s “high level of chemical cross-linking, which results in a semi-rigid product with a fine uniform cell structure” [3].

EVA is "not energy intensive," hence the company's material choice reduces this energy use [4]. However since EVA Foam is oil-based, petroleum must be obtained in order to process and produce it. Addidas owns many factories that are able to extract crude oil from the earth using drilling rigs and wells that, which are usually fueled by diesel generators and use 20 to 30 cubic meters a day on average [5]. Despite this, the corporation uses a select set of materials that are readily available globally, don't require much energy to transport, and don't require energy-intensive production methods. Due to the fact that EVA is a thermoplastic, the brand has a variety of methods for producing the same effects, including injection molding, extrusion, blow molding, and thermoforming. During the manufactining process Adidas utilizes injection molding inorder to inject the algae into the EVA Foam and compression molding in order to mold the runners. The pressure-driven flow during injection molding is both "internal and kinetic, and its mechanical energy is transferred into thermal energy (heat) [6]. Compression molding on the other hand is comprised of thermal and kinetic energy, and they are modeled based on the specifications of common equipment and the necessary molding pressure [7].

Adidas chooses trucks as their primary local shipping method and sea freight as their primary shipping method for shipments to other countries. The company's consideration of carbon emissions also has an impact on the choice since "even though our products have to deliver, it does not imply they can not be manufactured in a sustainable way" [8]. Most marine freights feed their propulsion systems with diesel or heavy fuel oil, which is known to contribute to global warming. Nonetheless, a Defra (Department for Environment, Food, and Rural Affairs) research [9] found that when compared to airplanes, the maritime technique produces roughly 98% less greenhouse gases. A typical ship transporting 2 tonnes of cargo over a 5000 km route will emit 150 kg of CO2 [9]. Adidas employs shipping as a result, even though it is not the optimum situation, in an effort to lower their carbon emissions. Also, the engine of a vehicle that transports items from one location to another is almost certainly powered by diesel. Without taking into account the effectiveness of converting thermal energy into electrical energy, which is likewise measured in kilowatt-hours, the unit of energy consumed is determined to be 33.7 kilowatt-hours (kWh). All this said, Addidas producers the runners in the USA, meaning they are only use freight and shipping to outside countries. This uses less energy compared to other manufacturers outside of the United States, and Yeezy ships directly to consumers who purchase their products online through the official website, eliminating the process of shipping to stores which interns conserves energy use.

No energy is needed to operate or maintain the shoes once the customer has purchased the item and has begun using it. The only energy required to power these sporty slides is chemical energy from the wearers since they are primarily intended to be worn as footwear. Adidas typically concentrates on recycling and reusing components at the end of a product's life cycle to create additional slides or even other products which goes back to the energy embodies in the product manufacturing process. The most frequent method used to recycle EVA is mechanical recycling (khinetic energy). Recycling materials are treated using this method with little to no alteration to their chemical composition. Mechanical recycling is used to recycle several thermoplastics, and EVA foam is typically crushed to create thinner sheets [11].This restricts the applications for recycled EVA but does not necessarily lower its quality. The composition of the basic materials makes it feasible to recycle the athletic slides. Through heating operations that result in melting and casting, both polymers are readily recycled. Due to the ease with which EVA melted, due to its low melting points, recycling requires less energy. However at the very end, if the consumer decides to discard of their shoes, they might end up in landfills they will decompose through thermal energy and go through a chemical change is that is not biodegradable [12].

While Adidas tries to reduce their energy usage in their operations, the product life cycle of Yeezy Foam Runenrs is energy intensive when combining all of the different types of embodied energy each step of the life cycle contains. Despite the efforts of Adidas to conserve the most amount of energy, the acquisition of the secondary raw material, specifically petroleum-based EVA foam has a detrimental impact on the environment and is energy intensive.

Adidas is trying to become sustainable the process they have, still utilizes energy, and although it is considerably less than the typical shoe, it is still not fully efficient. Although the slides are ejected with algae, they are still mostly composed of petroleum, which is oil based, and must be obtained through the many factories extract crude oil using drilling rigs and wells which is has negative effects on the planet and is energy intensive. Dispite the efforts of adidas to become more sustainable it is easy to see which life cycle stages demand the most energy since purchasing raw materials, producing goods, and processing those goods all require significant amounts of various types of energy, including mechanical, electrical, and thermal energy.

Works Cited

“Environmental Approach.” Adidas, Adidas, 2019, www.adidas-group.com/en/sustainability/compliance/environmental-approach/#/umgang-mit-dem-klimawandel/.

Foamcraft USA, LLC. “Ethylene Vinyl Acetate (EVA) Closed Cell Foam Parts.” EVA Closed Cell Foam Parts - Custom EVA Foam Fabricator | Foamcraft USA, LLC., https://www.foamcraftusa.net/eva-foam.html#:~:text=EVA%20foam%2C%20or%20ethylene%2Dvinyl,a%20fine%20uniform%20cell%20structure.

Lefteri, Chris. “Materials for Design,” Laurence King Publishing, 2014. ProQuest Ebook Central, https://ebookcentral.proquest.com/lib/ucdavis/detail.action?docID=1876185.

“Material Matters: Plant-Based Sneaker Uppers.” Sneaker Freaker, https://www.sneakerfreaker.com/features/material-matters/material-matters-plant-based-sneaker-uppers.

Meng, Fanran, et al. “Supporting Information for: Environmental Aspects of Use of Recycled Carbon Fiber Composites in Automotive Applications.” ACS Publications, 11 Oct. 2017.

Motawi, Wade. “Shoe Materials: Eva Midsoles.” Shoemakers Academy, 12 Nov. 2022, https://shoemakersacademy.com/shoe-materials-eva-midsoles/.

“Power Management Options For Offshore Oil & Gas Rigs.” New Used Generators Ends and Engines Houston TX Worldwide Power Products, https://www.wpowerproducts.com/news/how-to-power-offshore-oil-rigs/.

Siegle, L. "How ethical is shipping goods by sea." The Guardian. Retrieved September 5 (2014): 2017.

“Shear Heating.” Beaumont Technologies Inc, https://www.beaumontinc.com/injection-molding-glossary/shear-heating/#:~:text=During%20injection%20molding%2C%20the%20pressure,into%20thermal%20energy%20(heat).

Stanfield, Savanna. “Is Eva Eco-Friendly? 14 Facts You Should Know (+3 Alternatives).” Citizen Sustainable, 30 Nov. 2021, https://citizensustainable.com/eva-recyclable/.

Thompson, Ambler and Taylor N, Barry. (2008). “Guide for the Use of the International System of Units (SI) Archived June 3, 2016, at the Wayback Machine (Special publication 811). Gaithersburg, MD: National Institute of Standards and Technology.

Yuwei, Qin, and Arpad Horvath. “What Contributes More to Life-Cycle Greenhouse Gas Emissions of Farm Produce: Production, Transportation, Packaging, or Food Loss?” Resources, Conservation and Recycling, Elsevier, 7 Oct. 2021, https://www.sciencedirect.com/science/article/abs/pii/S0921344921005541.

Sean Batoon

Gian Ayson, Sania Heydarfadai

Professor Cogdell

DES 40A

24 February 2023

Waste Management

Yeezy Foam Runners: Waste and Emissions

As time progresses, we tend to discover and find new methods to solve long-generational problems. One of our planet's most significant issues today is waste dumping[1]. Waste in itself is a gaping hole that not only damages the environment but also future generations for the foreseeable future, however, the fight towards cleaning up the mess that we have caused ourselves isn’t a lost cause. Adidas a footwear and apparel company has made pledges to utilize methods of recycling and clean up their production practices to combat the issues of waste that accumulates every day. Take for instance its footwear collaborator Yeezy, which in 2020 introduced a shoe with a different take on how a traditional sneaker should look. The Yeezy foam runner uses part-farmed algae, and Ethylene - Vinyl Acetate (EVA) Foam. Although they claim it’s sustainable they aren’t recycled properly and it inevitably leads to more waste being included in the ever-growing problem of waste accumulation.

It should be noted that when looking at the overall product of the Yeezy Foam Runner it's not without a doubt a revolutionary shoe due to the fact of its twist on the materials it utilized in creating the shoe. However, looking at the materials, while yes they don’t follow the traditional structure of a conventional shoe, the involvement of a new material, farmed algae, paired with Ethylene-Vinyl-Acetate (EVA). Now when it comes to the waste aspect of EVA, EVA itself is not really a biodegradable material however, it really depends on the type of EVA it is as EVA has different variations up to at least 9 different variations. When looking at the waste aspect of EVA. One example of waste that can be from synthetic rubber is seen with scrap tires from automobiles as they tend to pill up in landfills and have also aided in feeding fires within landfills. The waste product of EVA are seen as defective midsoles and injection sprues. The increase of EVA being utilized has also caused landfills and more waste to accumulate as time goes on, the issue that comes with this is that not all EVA waste can be reprocessed, harvested algae is another raw material that is seen in the Yeezy foam runner and while not that much information is given about the actual waste that is included with the harvested algae that are associated with the Yeezy Foam Runner, we can assume that the harvest algae isn’t the only material that is utilized in the creation of the Yeezy Foam Runner. If the harvested algae are mixed with other components which in this case yes, is Ethylene-Vinyl-Acetate it is going to produce waste in the process of harvesting the algae[2].

When looking at the Yeezy Foam Runner production of the actual shoe, we established that EVA and harvested algae are the two primary components that make up the whole configuration of the shoe. The waste accumulates as those materials are being utilized but in the actual production process of the Yeezy Foam runner comes the issue of waste regarding defects. Yeezy doesn’t really disclose the details of what happens to their defects, however, for the sake of upholding good customer service with their consumers, any product that is defective upon delivery allows the consumer to get a full reimbursement when shipping the product back to Yeezy. I could not find a direct source or article that can state directly what happens to Yeezy products when they are defective but my assumption is that the defective pieces are either recycled into newer batches, or defective pairs are sold to other parts of the world at a discounted price to allow to at least liquidate the loss amount by gaining some return back. Defectives are usually products that most people do not want, and as such those products are usually sitting in a landfill where they’ll probably be with all the other shoes that are there too, whether it was defective or simply a shoe that nobody wants anymore. When looking at the transportation/distribution aspect of the Yeezy Foam Runner there is a lot to take into account in distribution because now its more than just the materials of the shoes that make the overall structure but now the overall usage of fuel that is needed to move the product around to areas of the world which result in emissions of carbon dioxide into the atmosphere.

Diving towards the use, reuse, and maintenance aspect of the Yeezy foam runner we can look at the studies of EVA waste and how it's been reused. EVA is used in a multitude of produced goods, such as seen in bags utilized to package frozen foods or used as a sealing layer[2], it is also used in equipment such as solar panels, yoga mats, and baby seats [3]. According to a scientific study done by Springer Link, methods of how EVA waste from footwear can be recycled and reused for other parts besides just sitting in a landfill where it’ll probably end up. These methods include utilizing mechanical methods such as measuring torque speed when mixing in order to rheological the EVA. Rheological is the term used to describe breaking down material, the reason, why studies are being done, is to combat the issue of EVA waste “The large productions of shoes using EVA also generates EVA waste”. With the issue of waste for EVA it has now looked at utilizing the waste as a raw material instead now. When looking at the recycling and disposal aspect of the Yeezy foam runner we can point our direction towards firstly the packaging of the shoe as it's just simply cardboard. When looking at the process of how recycling occurs with cardboard we have to dive down into where the cardboard first goes once it is thrown away, cardboard that is recycled first starts its journey towards china typically where they are soaked with water and removed of anything that is still attached to the boxes such as staples and is then rejuvenated into new batches of cardboard for the next set of product to roll out. When looking at amazon’s method of recycling with the amount of cardboard used every day to deliver packages to customers around the world daily, the practice of recycling has definitely helped towards the evergrowing issue with waste, but it hasn’t exactly cleaned up the issue with waste, as the in order to transport the cardboard for recycling takes up fossil fuel, in result makes more carbon dioxide being released into the air. When looking at how EVA can be recycled its measurement of viscosity was also taken into account as it can dictate whether it can be formed into new pieces of EVA[4]. According to an article published by Waste360, “These shoes end up in landfills, where they can take 30 to 40 years to decompose”[5]. Shoes that are disposed of most likely aren’t taken the right course of action in recycling and proper disposal procedures and as a result, add up to already large amounts of waste that sit in landfills. According to an article published by Green America[10],” The Environmental Protection Agency (EPA) estimates that 75 percent of the US waste stream can be recycled or composted, but we’re only doing so for just over 34 percent of it.” It all depends on the consumer during the whole life of the shoe and how they choose to dispose of it. While yes Adidas has made pledges towards recycling and being more environmentally friendly. It's the right step but it doesn’t mean everything is solved since the consumer can disregard how they dispose of their products.

To summarize, when looking at the Yeezy Foam runner is definitely something unique and different to the average consumer, backed by Adidas’s pledge of sustainability, however when looking at the waste products that come from the raw materials, from EVA, and from harvested algae to the amounts of EVA that are wasted and left in landfills during production, the fossil fuels utilized to recycle the cardboard, and the failure of proper disposal of EVA causing more shoes to sit in landfills. The ongoing issue of waste still continues to rise and the Yeezy foam runner while yes, does alleviate the ongoing issue it doesn’t necessarily remove the problem altogether. These methods still accumulate waste.

Bibliography

[1]” Tons of waste” The world counts

https://www.theworldcounts.com/challenges/planet-earth/waste/global-waste-problem

[2]Lopes, Diana “Natural and synthetic rubber/waste” Journal of Cleaner Production, vol 92, 2015, pp. 230 - 236. ScienceDirect

https://doi.org/10.1016/j.jclepro.2014.12.063

[3]Ollas, Tarja “Production of algae” [ Research project on algae waste], 2017

[4]Buonocore, G “Packaging Material” [Encylopedia of Food Safety]. Vol 3, 2014, pp. 384 - 396. Science Direct

https://doi.org/10.1016/B978-0-12-378612-8.00297-3

[5]” Plastic” “Plastic Identification Tool”. [Information about EVA], 2023,

[6]Júnior, C.Z.P., Mendonca, A.V., Fim, F.C. et al. Recycling EVA Waste: An Opportunity for the Footwear Industry-Rheological Properties of EVA Waste Composites Using Torque Rheometry. J Polym Environ 30, 2155–2164 (2022). https://doi.org/10.1007/s10924-021-02332-x

[7]“Material Matters: Eva Foam.” Sneaker Freaker, https://www.sneakerfreaker.com/features/material-matters/material-matters-eva-foam

[8]Rosa, Vanessa Bionda. Zattera, Ademir Jose. Poletto, Matheus. “Evaluation of Different Mechanical Recycling Methods of EVA Foam Waste.” Journal of Elastomers & Plastics.Vol.53, Issue 7, 08 Feb. 2021, https://doi.org/10.1177/0095244321990

[9] : Cheah, Lynette, Natalia Duque Ciceri, Elsa Olivetti, Seiko Matsumura, Dai Forterre, Richard Roth, and Randolph Kirchain. “Manufacturing-Focused Emissions Reductions in Footwear Production.” Journal of Cleaner Production 44 (April 2013): 18–29. http://hdl.handle.net/1721.1/102070

[10]Americans are bad at Recycling. here's how the world does it better. Green America. (n.d.). Retrieved March 15, 2023, from https://www.greenamerica.org/rethinking-recycling/americans-are-really-bad-recycling-only-beccause-were-not-trying-very-hard