Design Life-Cycle

assess.design.(don't)consume

Farhan Shaikh

DES40A (Cogdell)

Section A1 (Justin)

16 March 2023

Roomba 614 Research Paper - Raw Materials

The Roomba, a smart vacuum invented by the company iRobot, is one of the most popular robotic consumer products ever produced. With the total number of sales exceeding 14 million, the Roomba has greatly changed the vacuum industry since its launch in the early 2000s (iRobot.com). It allows for consumers to have a vacuum tour their home and clean up the majority of messes along the way/ This smart vacuum has become a ubiquitous household cleaning device that utilizes a complex array of raw materials, manufacturing processes, and end-of-life management strategies, and thus, this research paper aims to examine the environmental impact of the Roomba through a comprehensive analysis of the raw materials used in its production, the manufacturing process, the potential for recycling and disposal, and the strategies that can be implemented to minimize its environmental footprint.

The Roomba Smart Vacuum is made up of a variety of materials, including plastic, metal, and electronic components. The body of the vacuum is typically made from ABS plastic, which is a lightweight and durable material that is commonly used in consumer electronics. The electronic components of the Roomba Smart Vacuum include sensors, motors, and batteries. These components are critical to the vacuum's ability to navigate and clean floors automatically. The sensors allow the vacuum to detect obstacles and navigate around them, while the motors power the vacuum's movement and suction. The batteries provide the power needed to operate the vacuum.

Polypropylene and ABS are the most commonly used plastic types for the Roomba's components. Polypropylene is durable, lightweight, and resistant to chemicals, making it ideal for the Roomba's dustbin. ABS, on the other hand, is strong, tough, and resistant to high temperatures, making it suitable for the Roomba's outer shell. The ABS plastic that is used in the body of the Roomba is made through the process of emulsion. “ABS plastic is made when acrylonitrile and polystyrene monomers are polymerized with butadiene rubber to create acrylonitrile butadiene styrene (ABS). This blending is typically accomplished using an emulsification process” (What is ABS Plastic). The reason the body of the Roomba is made with this material is because it's durable, while also allowing for the vacuum to not break while bumping into objects, or break the objects that it bumps into. The next part of the Roomba is the wheels. These are made from metals and rubber, which are used to allow for smooth movement throughout the house. Both these materials are gathered from China and Malaysia. “iRobot works closely with its contract manufacturers, Jabil, Inc., BYD Electronic (International) Company Limited (“BYD”), Kin Yat (HK) Holdings Limited (“Kin Yat”) Simatelex Manufactory Co. Ltd. (“Simatelex”) and VS Industry Berhad (“VS Industry”) to manufacture iRobot products” (iRobot.com). In addition to these parts, the Roomba also has 5 main motors, as well as 2 different sensors within the body. There is 1 motor for each wheel, and 1 which is dedicated solely for the vacuum. The motor is made of copper wire, while the gears and axles are typically made of steel. The metal components provide strength, durability, and reliability to the Roomba, ensuring it can function seamlessly over an extended period. The wheels and other moving parts of the vacuum are typically made from metal, which provides strength and durability. The 2 main sensors are piezoelectric sensors and cliff detector sensors. These piezoelectric sensors are made from materials such as lead zirconate titanate (PZT), quartz, or lithium niobate which respond to pressure with a voltage output. “While we use our eyes to see, a Roomba uses infrared and photocell sensors to navigate around a room. These sensors each serve a different purpose: cliff sensors let the vacuum know when it’s near a ‘cliff,’ such as stairs or a balcony. If it senses this, the vacuum will back away from the ledge. Similarly, wall sensors let the vacuum know a wall is nearby, but Roomba will follow the path of the wall instead of retreating” (Tressler). These infrared detector materials are based on compound semiconductors made of III-V elements such as indium, gallium, arsenic, antimony, or on the II-VI elements mercury, cadmium and telluride, or on the IV-VI elements lead, sulfur and selenide (Xenics). Lastly, what powers the Roomba is the Lithium-Ion battery that's contained within the unit. According to the Clean Energy Manufacturing Analysis Center (CEMAC), “Critical raw materials used in manufacturing Li-ion batteries (LIBs) include lithium, graphite, cobalt, and manganese.”

As mentioned previously, iRobot, the company that owns the Roomba smart vacuum, obtains most of their materials from China and Malaysia, which is also where they are mostly manufactured. The manufacturing process typically involves the assembly of components into the final product. The plastic components are injection molded, while the metal components are typically stamped or machined. The electronic components are assembled onto printed circuit boards, which are then connected to the rest of the vacuum. Once the vacuum is assembled, it undergoes testing to ensure that it meets quality standards. The testing process typically involves running the vacuum through a series of cleaning tests to ensure that it can clean floors effectively. The main parts that require assembly are the piezoelectric and cliff detector sensors, since there are multiple parts that fit together in order to create the physical sensor.

Once the Roombas are manufactured, they need to be transported to retailers or directly to customers. The Roomba Smart Vacuum is distributed through a variety of channels, including online retailers, brick-and-mortar stores, and direct-to-consumer sales. The vacuum is typically packaged in a cardboard box, which contains the vacuum, charging dock, and accessories.The transportation process involves the use of trucks, trains, ships, and planes to move the Roombas from the manufacturing facility to their final destination. The transportation process can have a significant impact on the environment, as it requires the use of fossil fuels and emits greenhouse gasses.

Maintenance is another important aspect of the Roomba's lifecycle. Regular maintenance is essential to ensure the Roomba continues to function properly and efficiently. The maintenance process involves cleaning the Roomba's brushes, filters, and other components to prevent clogs and ensure optimal performance. The Roomba's battery also needs to be maintained to ensure it continues to hold a charge and provide sufficient power to the Roomba's motor. In addition to this, Lithium-Ion batteries are mostly manufactured in China, which also significantly adds onto the negative environmental effects associated with obtaining the battery in the first place.

When the Roomba Smart Vacuum reaches the end of its useful life, it can be recycled. “In 2021, approximately 132,000 pounds of iRobot batteries were recycled in North America, up 18% from the prior year” (iRobot.com). The plastic components can be melted down and reused to create new plastic products, while the metal components can be recycled to create new metal products. The electronic components can also be recycled, although this typically requires specialized equipment and processes. In addition to this, the Roomba is also an example of a product that aligns with the Responsible Business Act (RBA), which is a set of principles that promote sustainability, ethical practices, and social responsibility in business operations. The Roomba's use of raw materials and its manufacturing process incorporate environmentally-friendly practices, such as the use of recyclable materials and the use of automation to reduce energy consumption and waste (iRobot.com).

In conclusion, the Roomba Smart Vacuum is made up of a variety of materials, including plastic, metal, and electronic components. The manufacturing process involves the assembly of these components into the final product, which is then distributed through various channels. The vacuum requires regular maintenance to ensure that it operates effectively and can be recycled at the end of its useful life. Understanding the materials used in the Roomba Smart Vacuum can help us better understand the environmental impact of this popular household cleaning device.

Bibliography

Aram. “Piezoelectric Sensors - How Do Piezoelectric Sensors Work.” Sensor Works, 29 July

2022, https://www.sensor-works.com/how-do-piezoelectric-sensors-work/#:~:text=These%20sensors%20are%20made%20from,they%20generate%20a%20voltage%20output.

Benedik, Blaž et al. “Prediction of vacuum cleaner motor brush life: a regression approach.” Iet

Electric Power Applications 9 (2015): 569-577.

Benedik, B., Taškova, K., Tavčar, J. and Duhovnik, J. (2015), Prediction of vacuum cleaner

motor brush life: a regression approach. IET Electric Power Applications, 9: 569-577. https://doi.org/10.1049/iet-epa.2014.0437

Flynn, AM. “Combining Sonar and Infrared Sensors for Mobile Robot Navigation.” The

International Journal of Robotics Research, Dec. 1988.

Gautschi, G. (2002). Piezoelectric Sensors. In: Piezoelectric Sensorics. Springer, Berlin,

Heidelberg. https://doi.org/10.1007/978-3-662-04732-3_5

Indonesian Journal of Electrical Engineering and Computer Science Vol. 18, No. 2, May 2020,

pp. 745~749 ISSN: 2502-4752, DOI: 10.11591/ijeecs.v18.i2.pp745-749

J. L. Jones, "Robots at the tipping point: the road to iRobot Roomba," in IEEE Robotics &

Automation Magazine, vol. 13, no. 1, pp. 76-78, March 2006, doi: 10.1109/MRA.2006.1598056.

Mahmud, M. A. Parvez, et al. “Comparative Life Cycle Environmental Impact Analysis of

Lithium-Ion (Liio) and Nickel-Metal Hydride (Nimh) Batteries.” MDPI, Multidisciplinary Digital Publishing Institute, 18 Feb. 2019, https://www.mdpi.com/2313-0105/5/1/22.

“Supply Chain Oversight.” IRobot,

https://about.irobot.com/Corporate-Social-Responsibility/Responsible-Manufacturing.

Tressler, James F., et al. “Piezoelectric Sensors and Sensor Materials - Journal of

Electroceramics.” SpringerLink, Kluwer Academic Publishers, 1998, https://link.springer.com/article/10.1023/A:1009926623551.

Tressler, J.F., Alkoy, S. & Newnham, R.E. Piezoelectric Sensors and Sensor Materials. Journal

of Electroceramics 2, 257–272 (1998). https://doi.org/10.1023/A:1009926623551

Xometry, T. (2022, June 9). What is ABS plastic? Xometrys RSS. Retrieved March 2, 2023, from

https://www.xometry.com/resources/materials/abs-plastic/

Allen Ma

Isabella Rogers & Farhan Shaikh

Professor Cogdell

DES 40A

14 March 2023

Roomba 614 Life-Cycle: Embodied Energy

Robots are present in many sectors of society ranging from assisting in manufacturing, performing online services as artificial intelligences, to even simplifying tasks in the home. The Roomba 614 is a robot vacuum cleaner produced by the company, iRobot, which was founded in 1990 by MIT roboticists. (“History”). While the Roomba 614 weighs a total of 9.92 pounds, the energy used in the robot vacuum’s lifetime should be considered as the Romba is made of various materials and parts that require vast quantities of energy to manufacture.

The components and the product itself are manufactured in China by factories contracted by iRobot while the sourcing of the raw materials is unknown. (“Supply Chain Oversight''). The Roomba 614 is divided into seven categories of components: the motherboard, chassis, covers, wheels, motors, brushes, and sensors. Parts such as the chassis, covers, wheels, and brushes are made of petroleum-based products such as ABS plastic, nylon, and synthetic rubber. The petroleum drilling rigs which extract the petroleum from the earth are commonly fueled by diesel and convert the fuel into electricity using their diesel combustion engines. (Stuver 159). This process involves the usage of thermal energy to ignite the fuel and produces chemical energy as the diesel burns and generates electricity. For the motors and the screws used to hold the Roomba 614 together, iron is obtained from iron ore mined by mining machines fueled by diesel or coal for iron mines in China. (Liu 753). Once again, the mining combustion engines use thermal energy to ignite the coal or diesel to release chemical energy within to produce electricity. Silica and quartz are also raw materials for the Roomba 614’s various sensors and they are mined with similar diesel or coal fueled machines. After the raw materials are obtained, they are sent to other locations to be processed.

Petroleum is transported to oil refineries to be processed into products such as those used in the Roomba 614. ABS plastic is made from blending the petroleum-based plastics, styrene and acrylonitrile, with a petroleum-based rubber, butadiene. (Xometry). Petroleum is thermally cracked with high temperature steam reaching 816 degrees celsius, breaking into chemicals such as benzene which is distilled, dehydrogenated into styrene, and then distilled once more for purification. (Morimoto and Tatsumi). This process involves thermal energy from burning the chemical energy of fuel such as coal to heat water to create steam which heated the petroleum until it separated. Acrylonitrile is made from having a “fluidized bed reactor in which propylene, ammonia, and air contact a solid catalyst at 400-510 °C.” (National Center for Biotechnology Information). Propylene is another product of using thermal energy to crack petroleum and it is heated with air and ammonia which is another instance of thermal energy being used. Butadiene is a “by-product of ethylene production from steam crackers” which means it is also a material which involves the usage of chemical and thermal energy. (White 1). While information about ABS plastic materials being emulsified to form ABS plastic could be found, the emulsification process is not further explained. Information about the energy used to produce nylon could also not be found. The patent for the brushes only mentions the bristles being made from a rigid polymer material. (Schregardus and Gschrey). Meanwhile, the rubber used to make the treaded wheels is expected to come from the products of petroleum steam cracking.

Iron is a primary material combined with carbon to form the steel used in the Roomba 614 for the DC brushed motors and metal screws. Steel is made from “pig iron produced by the blast furnace” which is then pounded to introduce carbon into the iron to create steel. (Yellishetty, Sec 4.1). So thermal energy is used to heat the iron and kinetic energy is used when hitting it. There is information about other types of steel screws that are created by forming threads using a “hot rolling process” which involves kinetic energy from rolling the heated steel between rollers. (Pater). Heating the steel is an example of thermal energy. Moving on to iron used for magnets, the iron is melted in an electromagnetic furnace at 1600 degrees celsius, cast into a sand mold and cooled down, tied to a copper tube which is then packed and sealed with silica sand in a larger tube, and then heated in a furnace once more. (“How Are Magnets Made?”). Afterward, both ends of the tube are fixed with clamps, before passing an electrical current through the tube to make the metal slightly magnetized. (“How Are Magnets Made?”). Finally, the slightly magnetized metal is made magnetized by receiving an electric current from a magnetizing machine which turns it into a magnet. (“How Are Magnets Made?”). The process of making a magnet involves the burning of fuel to heat the furnace which is chemical and thermal energy, then there is thermal energy involved in melting the iron, and then there is electrical and electromagnetic energy used to make the iron a magnet.

While it is known that quartz crystals are used to make piezoelectric sensors, information about the processes used to turn them into sensors could not be found. Specifics about the motherboard are not given by any of the pages on the iRobot site so there is no information about how the motherboard is made.

The DC brushed motors are made from magnets, metal plates which are presumably iron, and copper wire for the windings are made from smelted copper which is rolled into a wire. “Most copper is extracted by smelting sulfide ores.” (Gaines). So the copper wire for the motors are made using thermal energy when heating the sulfide ore to extract the copper and kinetic energy from the process of rolling it into a wire.

The ABS plastic is heated and then injected into molds to make the chassis and covers of the Roomba 614. This information is based off of websites who offer ABS injection molding services. “First, we injection mold an approximate shape of the ABS part. We then machine the part to meet the tolerance requirements while milling ports, threads and undercuts.” (“Expert ABS Plastic Machining”). The process of injection molding would require the ABS plastic to be heated so that involves thermal energy and once the plastic is molded, if Roomba parts are also machined to meet certain requirements of the producer, then mechanical/kinetic energy is used by shaping the plastic. The machines used to inject and machine the plastic are likely to use electricity produced from burning fossil fuels so chemical energy would also be involved.

As the Roomba 614 is a product assembled from various electronics, plastic parts, and needs to be wired together, it is assumed that the last steps of assembling the product require humans. Humans eat biomatter and convert it into chemical energy which allows them to move their bodies and perform tasks like assembling a Roomba 614. After assembly is the transportation and distribution of the robot vacuum cleaner.

Roombas are shipped by water and ground vehicles. The majority of cargo ships use heavy fuel oil which has to be heated up because of how thick it is before being used in the combustion engine. (“What Is Heavy Fuel Oil?”). So for maritime transportation, thermal and chemical energy are used. Thermal and chemical energies are used in ground shipping by trucks that mainly use diesel combustion engines because thermal energy is needed to ignite the fuel to burn the chemical energy. Once the Roomba 614 reaches a location such as a store or customer’s home, it will eventually be used.

The Roomba 614 runs on a lithium ion battery which can be recharged at the home base charging station. This home base would be plugged into the customer’s residence’s outlet, receiving energy from possibly fossil fuel depending on the electricity provider. After searching for separate batteries on the iRobot website because they don’t include the specific battery used in the Roomba 614 specifications, it is believed that the Roomba 614 uses an 1800 lithium ion battery because it’s compatible with the model. (“Roomba® 1800 Lithium Ion Battery.”).

Moving onto the recycling and waste management of the Roomba 614, according to iRobot, the only part consumers recycle is the lithium ion battery. They have a guide dedicated to explaining how to properly recycle the battery. (“Product End of Life and Recycling” ). The two options require the customer to either “[return] it to the distributor/dealer…or [deposit] it in a designated collection point.” (“Product End of Life and Recycling”). This would mean that transportation vehicles would be required to pick up the batteries and transport them to sites to be recycled which would involve thermal and chemical energies being used to burn fuel and power the vehicle.

The Roomba 614 is smaller than the traditional upright vacuum cleaner, yet it still is made up of many parts that require various types of energies to obtain the resources, manufacture and assemble, transport, be used by the consumer, and finally discarded or recycled.

Works Cited

“History.” IRobot, https://about.irobot.com/history.

“Supply Chain Oversight.” IRobot,

https://about.irobot.com/Corporate-Social-Responsibility/Responsible-Manufacturing.

Stuver, Susan, et al. “A Comparison of Air Emission Estimation Methods for ... - Ccsenet.org.”

Canadian Center of Science and Education, Canadian Center of Science and Education,

19 May 2015,

https://www.ccsenet.org/journal/index.php/enrr/article/download/48989/26311.

Liu, Zhu, et al. “Embodied Energy Use in China's Industrial Sectors.” Energy Policy, vol. 49,

2012, pp. 751–758., https://doi.org/10.1016/j.enpol.2012.07.016.

Xometry, Team. “What Is ABS Plastic?” Xometrys RSS, Xometry, 9 June 2022,

https://www.xometry.com/resources/materials/abs-plastic/.

Morimoto, H, and M Tatsumi. “US3763015A - Process for the Separation of Styrene from

Thermally Cracked Petroleum by Polymer Inhibition and Extractive Distillation.” Google

Patents, Google, 1971, https://patents.google.com/patent/US3763015A/en.

National Center for Biotechnology Information. "PubChem Compound Summary for CID 7855,

Acrylonitrile" PubChem, https://pubchem.ncbi.nlm.nih.gov/compound/Acrylonitrile.

Accessed 16 March, 2023.

White, Wm. Claude. “Butadiene Production Process Overview.” Chemico-Biological

Interactions, vol. 166, no. 1-3, 2007, pp. 10–14.,

https://doi.org/10.1016/j.cbi.2007.01.009.

Schregardus, Thomas P., and Travis James Gschrey. “US11103113B2 - Brush for Autonomous

Cleaning Robot.” Google Patents, Google, 2017,

https://patents.google.com/patent/US11103113B2/en.

Yellishetty, Mohan, et al. “Iron Ore and Steel Production Trends and Material Flows in the

World: Is This Really Sustainable?” Resources, Conservation and Recycling, vol. 54, no.

12, 2010, pp. 1084–1094., https://doi.org/10.1016/j.resconrec.2010.03.003.

Pater, Z., et al. “New Method of Thread Rolling.” Journal of Materials Processing Technology,

vol. 153-154, 2004, pp. 722–728., https://doi.org/10.1016/j.jmatprotec.2004.04.154.

“How Are Magnets Made?” Stanford Magnets, 4 June 2020,

https://www.stanfordmagnets.com/how-are-the-magnets-made.html.

Gaines, L. L.. Energy and materials flows in the copper industry. United States: N. p., 1980.

Web. doi:10.2172/6540399.

“Expert ABS Plastic Machining: Consistently Machined ABS.” Jaco Products, Inc., 14 Feb.

2023, https://jacoproducts.com/injection-molding/abs-plastic-machining/.

“Marine Fuels: What Is Heavy Fuel Oil?” Clear Seas, 27 May 2020,

https://clearseas.org/en/blog/marine-fuels-what-is-heavy-fuel-oil/.

“Roomba® 1800 Lithium Ion Battery.” IRobot,

https://www.irobot.com/en_US/roomba-1800-lithium-ion-battery/4502233.html.

“Product End of Life and Recycling.” Global.iRobot.com,

https://global.irobot.com/en/Compliance/Product%20Recycling.

Isabella Rogers

Farhan Shaikh & Allen Ma

Professor Cogdell

DES 40A

March 2023

Waste and Emissions of the Roomba Vacuum

Since 2002, robot vacuums have been a constantly evolving convenience in the world of consumer electronics and automated cleaners. IRobot has become a standout company in the production of robot vacuums, specifically with their line of Roomba vacuums. Within the life cycle of the Roomba vacuum there are several intricate components that make up the machine, and within those components exists procedures that produce various wastes and emissions. Even though IRobot consistently states about “responsible manufacturing,” it is essential for this company to consider overall circumstances such as, the volume of waste being produced through raw material extraction, management of distribution wastes, and overall disposal of the item once it enters the customer’s home.

There are several bits and pieces that comprise the Roomba vacuum, specifically the Roomba 614 model. ABS plastic makes up a majority of the components; this plastic is a petroleum-based, secondary material formed from acrylonitrile, butadiene, and styrene. The wastes created during this synthesis process of collecting and exporting these materials come from fossil fuels. The resulting emissions include air pollution and toxic water runoff. In order to produce a majority of the mechanical and electrical components there are a lot of heavy metals needed: lead, zirconium, titanium oxide, iron, copper, tin, steel, and lithium. These resources all require mining deep into the Earth, specifically in countries such as Brazil, South Africa, Spain, and China. The water waste created from mining can leach into nearby water systems, infecting the water supply with chemical runoff like lead and mercury. Mining relies on fossil fuels; coal and diesel powered machinery are necessary, but the resulting carbon dioxide emissions are significant. Without proper management or solutions these raw materials create large amounts of waste and emissions that harm the environment.

According to their website, “since the Roomba robotic vacuum cleaner was first introduced in 2002, iRobot products have been produced by contract manufacturers in China”(iRobot). Kin Yat Holdings Ltd. is one of the primary manufacturers of Roomba components and they have deliberately stated in the “Corporate Social Responsibility Approach” (KYH Ltd. 3) portion of their business report that they make conscious efforts to reduce their operational carbon footprint. This is put into practice by implementing automated systems and green production, for example “ eliminating processes such as spraying and pad painting as well as modifying injecting moulding process, in order to reduce the use of chemicals and generation of hazardous waste”(KYH Ltd. 10). They also claim to perform sample checks on “raw materials, semi-products, and final products, to ensure safety and quality of products” (KYH Ltd. 10). During the injection moulding process any defective moulds are re-melted and mixed into new batches of plastic; implementing this procedure cuts down on solid waste that would end up in the landfill. As far as numbers are concerned, in 2019 Kin Yat generated “5,843,619 tonnes of waste, of which 99% was recycled, incinerated, or sent to licensed companies for further treatment” (KYH Ltd. 27). This implies that 1% of this waste was sent to the landfill, if the conversions are done, that results in about 64,000 tons of waste being put into the ground. As far as wastewater is concerned, they have proper procedures in place for storing and treating waste water until it is suitable to be discharged. A majority of air emissions consist of Nitrous Oxides, Sulfur Oxides, and particulate matter, however they do have plans to explore new methods of electricity generation that do not result in such large quantities of pollution. Overall, it is refreshing to see such transparency from a manufacturer of waste, but also their willingness to take initiative in creating solutions for a greener future.

One of the major points of emissions comes from the distribution of the Roomba614. This product is available in most major retailers, most centrally, the US, Europe, and Asia, as well as carried by e-commerce sites like Amazon. Due to the fact that lithium ion batteries cannot be transported in the air because of “stringent transport regulations”(iRobot), they have to be shipped via ground and water transportation. The wastewater that large cargo ships discharge is called “ballast water.” This is often riddled with “a variety of biological materials” including “invasive, exotic species that can cause extensive ecological and economic damage to aquatic ecosystems along with serious human health problems”(Walker et al.). This water needs to be properly managed to avoid potential environmental risks. Air pollution emissions created during transport and distribution included Carbon Dioxide (CO₂), Nitrogen Oxides (NOₓ), Sulphur Oxides (SOₓ), and other particulate matter (black carbon/smog). When then the materials are transported over ground they are usually in semi trucks. These large vehicles are much smaller than cargo ships, but they still require fossil fuels to run; this results in similar emissions of CO₂, SOₓ, etc. In sum, the grand amount of emissions generated by distribution might not specifically be for Roombas, but it is important to consider their contributions to it.

The Roomba 614 has several components that the user has to maintain throughout its consumer lifecycle. Straight out of the package, the user can recycle the box and corrugated carton the vacuum comes in, however the item is wrapped in a plastic that can only be recycled in facilities and not household recycling bins. The IRobot website suggests that with proper care of the vacuum (i.e. cleaning the brushes weekly, and the sensors and wheels monthly) the user should replace the brushes, extractors, and front caster wheel “every 6-12 months,” and the filter “every 2 months”(iRobot). Luckily, the Roomba has a very modular design so the product has easily accessible and replaceable individual components which lead to a prolonged lifespan and increased obsolescence, ultimately decreasing overall waste that would come from having to replace the entire unit.

Fortunately, iRobot has an entire section of their website dedicated to the recycling of their products. It is important that lithium ion batteries are recycled properly because if these components get thrown into the environment it will have very harmful effects. One of the “specific hazards” (Kubota 1), is the electrolytes within the battery which will create hydrogen fluoride if it comes into contact with water. Hydrogen fluoride can be incredibly toxic to living things and also creates wet acid deposition (acid rain) when dissolved into the air, fog, rain, etc. Hopefully with the help of the iRobot recycling manual, the consumers will be able to disassemble their Roomba vacuums in order to be properly disposed of with minimal wastes.

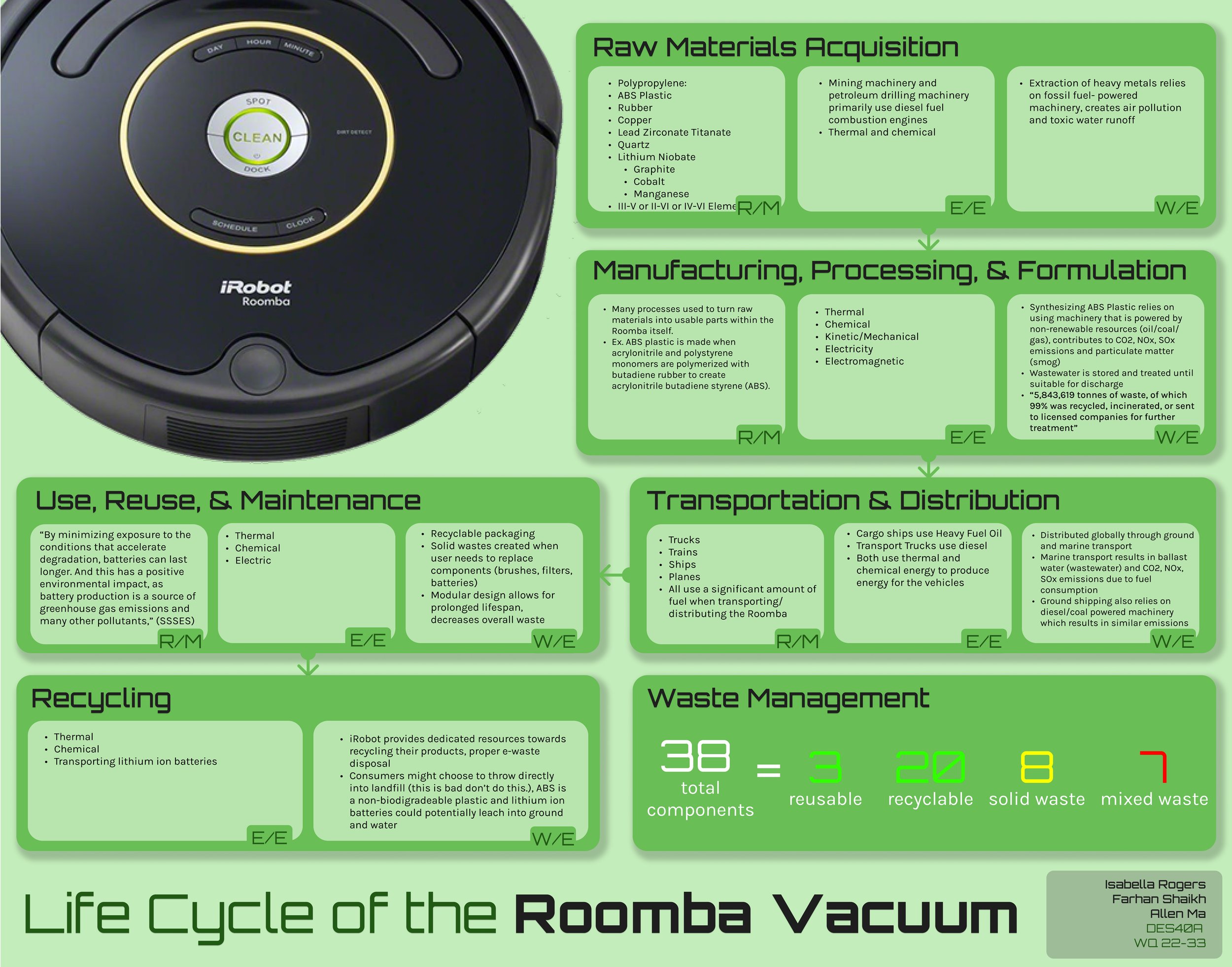

The overall waste management of the Roomba vacuum can be broken down into four parts: recyclables, reusables, solid wastes, and mixed materials that have to be removed and treated separately. There are 38 individual components of the Roomba vacuum that are sorted into these categories and break down into the following: 3 reusables, 20 recyclables, 8 solid wastes, and 7 mixed materials. Having this many recyclable and reusable components is very fortuitous, however the likelihood that the consumer is going to break down the vacuum itself is very slim, that is why it is essential that it is taken to proper e-waste disposal facilities.

In essence, the Roomba robot vacuum is a product that cleans but it is not necessarily a “clean” product. With the sheer amount of plastic and metal components that need to be processed and manufactured in order to make this product it is important that the consumer is enlightened about this process in order to make a better informed decision. There are several steps of the Roomba lifecycle to take into consideration when claiming “environmental responsibility”, and hopefully with this analysis the company will be able to take larger steps in managing its ecological outputs from start to finish.

Bibliography

Walker, Tony R.; Adebambo, Olubukola; Del Aguila Feijoo, Monica C.; Elhaimer, Elias; Hossain, Tahazzud; Edwards, Stuart Johnston; Morrison, Courtney E.; Romo, Jessica et al. (2019). "Environmental Effects of Marine Transportation". World Seas: An Environmental Evaluation. pp. 505–530. doi:10.1016/B978-0-12-805052-1.00030-9. ISBN 978-0-12-805052-1. https://dx.doi.org/10.1016%2FB978-0-12-805052-1.00030-9

TUVRheinland. “Reuse and Recycling Manual.” Nov. 2015. PDF.

“Fluoride Compounds: Sources of Emissions.” DCCEEW, 30 June 2022, https://www.dcceew.gov.au/environment/protection/npi/substances/fact-sheets/fluoride-compounds-sources-emissions.

“Air Pollution & Marine Shipping.” Clear Seas, 6 Nov. 2020, https://clearseas.org/en/air-pollution/#:~:text=Commercial%20ships%20burn%20fuel%20for,SOx)%20and%20particulate%20matter.

Australian and New Zealand Environment and Conservation Council (ANZECC) (1992) Australian Water Quality Guidelines for Fresh and Marine Waters

Li, Jun, et al. “Degradable Piezoelectric Biomaterials for Wearable and Implantable Bioelectronics.” Current Opinion in Solid State and Materials Science, vol. 24, no. 1, 6 Feb. 2020, p. 100806., https://doi.org/10.1016/j.cossms.2020.100806.

Mehmet Sunar, 2.22 “Piezoelectric Materials”, Editor: Ibrahim Dincer, Comprehensive Energy Systems, Elsevier, 2018, Pages 696-719, ISBN 9780128149256, https://doi.org/10.1016/B978-0-12-809597-3.00248-0.

Rutkowski, Joseph V., and Barbara C. Levin. “Acrylonitrile-Butadiene-Styrene Copolymers (ABS): Pyrolysis and Combustion Products and Their Toxicity?a Review of the Literature.” Fire and Materials, vol. 10, no. 3-4, 1986, pp. 93–105., https://doi.org/10.1002/fam.810100303.

Kubota, Tsutomu. “Declaration of Conformity.” Panasonic Industrial Devices Sales Company of America, 9 Jan. 2023, The Colony, Texas.

Long Hu, Yiming Miao, Gaoxiang Wu, Mohammad Mehedi Hassan, Iztok Humar, iRobot-Factory: An intelligent robot factory based on cognitive manufacturing and edge computing, Future Generation Computer Systems, Volume 90, 2019, Pages 569-577, ISSN 0167-739X, https://doi.org/10.1016/j.future.2018.08.006.

“Environmental, Social, and Governance Report.” Kin Yat Holdings Limited, 2019, http://www.kinyat.com.hk/pdf/companynews_pdf2019/e_0638esg_191011.pdf.