Design Life-Cycle

assess.design.(don't)consume

Daisy Scott

Des 40A

Professor Cogdell

01 December 2018

Materials Throughout the Life Cycle of Washi Tape

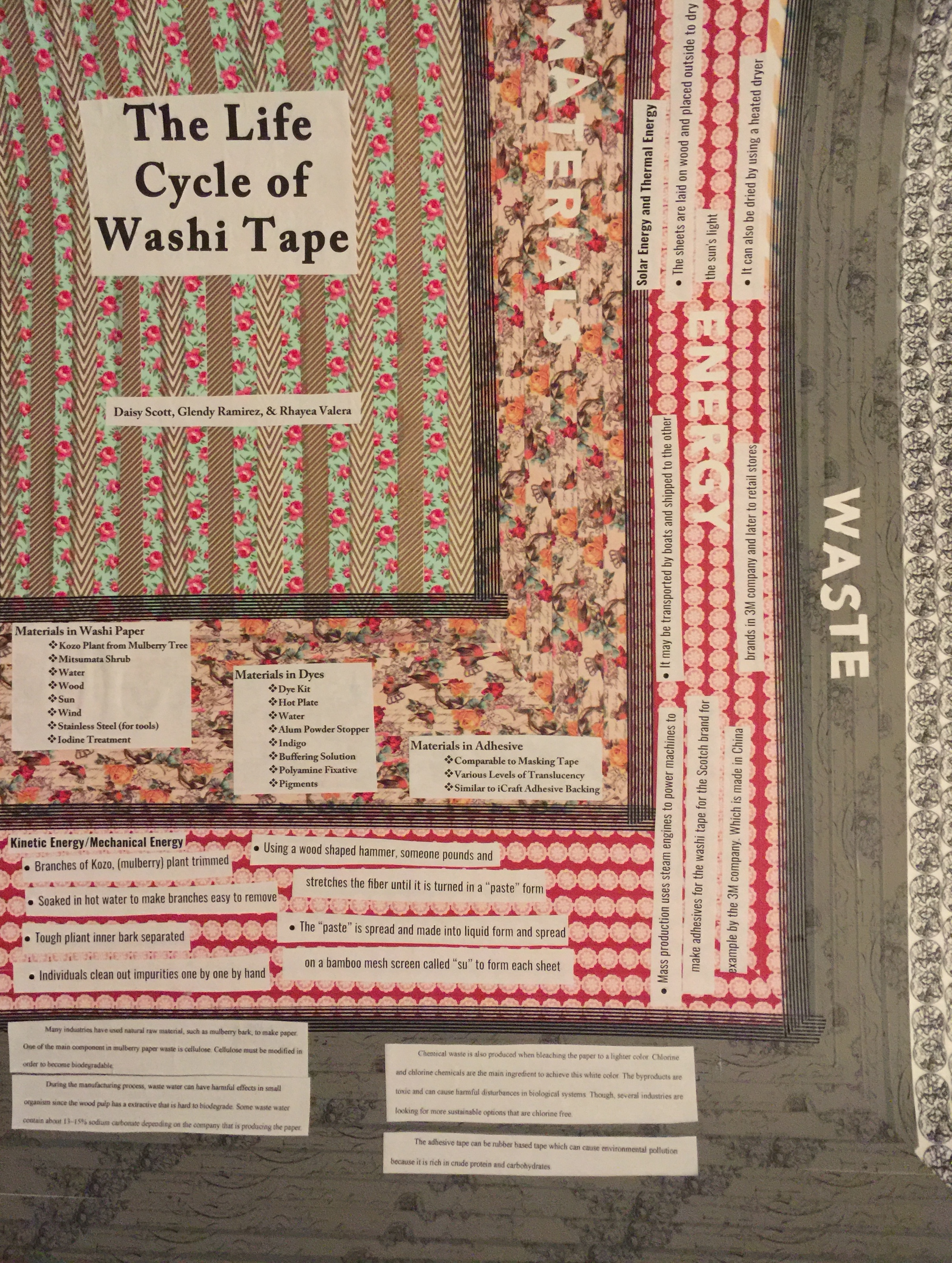

Although Washi is an ancient papermaking technique, the scrapbooking and craft communities have recently resurrected the tape. The paper now has adhesive and decorative patterns that make any project stand out. Washi tape was traditionally started in Japan in the 8th century, as a paper making technique, using pulps from different trees and plants. It is now mass produced by companies all over the world, and sold in most, if not all craft stores in the United States. In looking at the sustainability of materials used in Washi tape, it is vital to break these resources down between the materials used in making the paper itself, dyeing the paper, and the adhesive used. In looking at these materials and their processes, it is found that washi tape is not only a more decorative adhesive, but also a more environmentally friendly form.

Since the beginning of Washi paper’s invention, there have been many different offshoots of paper making that provide diverse qualities. It is important to look at these varieties in order to determine which is the most viable option for the environment.

The first raw material used to create traditional Washi paper is the Kozo plant that comes from a mulberry tree. The outer bark of the Kozo plant is stripped down after being steamed in a bath of water. Then, the stripped bark is placed in a flowing stream of clean water for several days. Next, the bark is boiled until it is soft. Thus, another raw material used in this process is water. A wooden stick is used to beat the fibers, once they have been soaked and the impurities have been removed. This beating process happens so that the paper makers can separate the fibers. This process helps flatten out the fibers in a sheet-like form.

There is also wood used to make a strainer for the water to run through the paper. Another use for wood in this paper making process includes that of the drying area. The paper then dries from the sun and the wind, which are also primary sources of energy (UNESCO). Another plant used to make Japanese paper is the mitsumata shrub. Other tools that are used in more contemporary times include stainless steel and wood, often passed down through apprenticeships (Lee). An iodine treatment is also applied to the paper, which prevents thermal decomposition. In addition, the degree of crystallinity- the internal rigid structure of a fiber, (TXC 006) and electrical conductivity of the paper is improved by this iodine heat treatment (Kazuo). Once the paper is made, further materials are used in the dying process.

The dyeing process adds other materials and properties to the Washi process. Not only is it important to see if these materials are renewable, but also to find out if there are any toxic remnants after the papers are dyed. In addition, there are different ways of dying based on what the needs are for the paper. For instance, at the Awagami fair, a woman displays somewhat of a tie-dye effect on her paper. She first folds the paper multiple times, in order to establish a pattern where the dye will set. The woman does this step multiple times while she heats the dye on a hotplate. The dye she is using is from Orizome-shi paper dying kit, which is associated with the fair. Water is added to the dye on the hotplate. During this process, the woman starts dipping the folded white paper into multiple dyes. After she is done with the dyes, she rinses the paper in a bowl of water and then presses it dry into a waste bowl. The kit does not say what the dyes are made of, but it does say that an Alum color stopper powder is included (Awagami Factory).

Another person who worked at the Awagami fair with paper dyeing was a woman named Alice Austin. Austin worked with another woman, who taught her to dye with indigo. In this demonstration, Austin placed paper in a vat of dye for a few minutes and then set it up to oxidize and dry for about three minutes. After this, she washes the paper with water and re-dips the paper in the indigo for an additional five minutes. When the paper first comes out of the vat of indigo, it has a yellow-y brown tint; only after the washing process do the blue shades become visible. When all of the layers of dye have been added, the paper must be washed in water for an hour. In the area that the women are working in, there is an indigo plant hanging on the wall, to show the artisans where the dye originated.

When the vats are shown again, there is a woman dusting a buffering solution into the indigo to achieve the proper pH balance. It is not stated what materials are in the buffering solution. I also did not find any steps in any of the processes that I looked at that included bleaching or any other source of preliminary surface coating to set the dye. However, in another article I was able to find the materials used in a synthetic fixative, so that the colors from the dyes last longer. The fixative is a polyamine, which is a synthetic polymer with high molecular weight (meaning it has high orientation and crystallinity, TXC006). This substance also has a neutral pH. In this journal, it also stated that the craftspeople using this dyeing technique used pigments from plants instead of dyes (Koretsky). After the dyes are made and set in the paper, the materials in the adhesive are utilized.

When looking for information on the specific materials for Washi tape, it was difficult to figure out what it is made out of exactly. Washi Magic compares Washi as being most comparable to masking tape. In comparing the adhesive used in Washi tape to other tapes and adhesives, it is found that Washi tape is preferable for many reasons, including multiple uses. Thus making this product recyclable. For instance, when peeled away from a surface, the washi tape does not break or pull off the surface on which it is attached. However, it is sticky and works in the same way as other types of tapes in this way. Depending on the brand of Washi tape, there are varying layers of translucency. This is more of a decorative aspect than a practical one, but it is still important to know the different varieties; as these have different performance qualities.

For instance, a craftsperson with the YouTube handle “Butterfly Planner” mentions that some of her more translucent Washi tapes break more frequently as they are removed from a surface, versus the more vibrant and fully colored tapes. Another benefit of Washi tape over other kinds of tape includes the ability to cut easily. While the tape is sturdy when placed on a surface, it is actually quite easy to tear the tape with one’s fingers. Thus, no extra materials are needed to remove the tape from the roll or the surface it is placed upon. In comparison to decorative tape, the ease of cutting is much better, as decorative tape has more of a plastic texture and requires other tools to cut the desired amount. Decorative tapes are also more likely to tear up the surface they are placed on, should one try to remove the tape (Sommers).

In addition to easy movability, washi tape is also a more decorative tape, works on all surfaces, and has the ability for the user to write on. Another similar crafting material that is similar to Washi tape is iCraft Adhesive Backing. I was also unable to find much information on the materials used in this product. However, in my research of the adhesive used, I found that the iCraft tape is likely to be the most comparable to the adhesive used with Washi paper. The iCraft tape is double sided, and is commonly used to adhere photographs to scrapbooks and other similar projects. While looking at Washi tape, it may seem like an easy process; however, when the materials are broken down, there is more complexity to this simple design. Even though the process is more complex, it is a more playful and ecologically friendly product than other adhesives and decorative papers.

The makers of Washi tape continue to maintain traditional materials and methods as much as possible, in order to deliver unique designs to consumers. There is also a keenness in using only natural materials whenever possible. In addition, even when there are secondary sources used, such as the binder and color stopper, the people who are making the papers attempt to get a pH that is at least neutral if not alkaline. Therefore, these artisans continue to try to not put out any chemicals that would put out acidic and toxic waste into the environment.

Bibliography

Akagi, Kazuo. “Efficient Preparation of Carbon Papers by Pyrolysis of Iodine Treated] Japanese Paper.” Journal of Analytical and Applied Pyrolysis, Elsevier, 30 Dec. 2011, www.sciencedirect.com/science/article/pii/S0165237011002403.

Austin, Alice, director. Indigo Dyeing at Awagami Paper in Japan. YouTube, YouTube, 27 Aug. 2015, www.youtube.com/watch?v=QqAHebIC01o&t=70s

Awagami Factory. Awagami Orizome-Shi Paper-Dyeing Demo. YouTube, YouTube, 11 Feb. 2017, www.youtube.com/watch?v=py3Fv1zpFfw&feature=youtu.be

Awagami Factory. Orizome-shi paper dying kit. http://www.awagami.jp/products/hobby/kit/index.html#8831001

(The website was in Japanese and did not translate very well, I cited the information that I could find.)

Butterfly Planner. What Is the Difference between Washi Tape and Decorative Tape. YouTube, YouTube, 21 Oct. 2017,Cae12810. Washi-Japanese Paper YouTube, YouTube, 27 Jan. 2012, www.youtube.com/watch?v=_E atPin7pQ&feature=youtu.be.

Erina. “Discover the Different Types of Washi Tapes.” Washi Magic. 2018, https://washimagic.com/different-types-of-washi-tape-part1/

Erina. “What is Washi Tape? Is it Similar to Normal Adhesive Tape.” Washi Magic. 2018, https://washimagic.com/what-is-washi-tape/

Koretsky, Elaine. “The Coloring of Pulp in Alkaline Papermaking.” Alkaline Paper Advocate. October 1988. http://cool.conservation us.org/byorg/abbey/ap/ap01/ap01-4/ap01-411.html

Lee, Aimee. “Indiana University.” Becoming a Papermaker: Best Practices from Japan to the U.S., American Folklore Society, 1 Jan. 1970, scholarworks.iu.edu/dspace/handle/2022/21501?show=full.

Michaels. “iCraft Adhesive Backing.” Michael’s, 2018, https://www.michaels.com/icraft adhesive-doublesided-tape-1-4-inch/D064401S.html#jmp-view-desc

Sun, Gang. “Crystallinity.” Classroom Lecture in TXC 006. Fall 2018 Quarter. University of California: Davis

Sommers. “United States Patent Application Publication.” Patent Application Publication, 12 Sept. 2013, https://patents.google.com/patent/US20130236703A1/en

UNESCO. Washi, Craftsmanship of Traditional Japanese Hand-Made Paper. YouTube, YouTube, 26 Nov. 2014, www.youtube.com/watch?v=J6C8ESEAeAo

Rhayea Valera

Des 40a

Professor Cogdell

6 December 2018

Waste and Emissions of Washi Tape

Washi is a traditional Japanese paper that in recent times has been combined with an adhesive tape to create Washi tape, which has created waste throughout its life cycle. Paper making in Japan was mentioned in the Chronicles of Japan. It talks about how Buddhist Priest brought the methods over from China around 610 AD. Over the years Japan has switched to using mulberry fibers as the method of paper making has become popular all over the region. Later it becomes part of the Japanese culture. For washi tape, it slowly became a huge trend when it was sold as a decorative masking tape in Japan. It was then picked up by scrapbookers outside of Japan. Since then, it has been a growing trend of washi tape in stores in many locations for many purposes. These products have a creative use to their functions throughout its life cycle, the amount of waste still remains. Although washi tape is a modernized collaboration of two different products, it can become a health hazard in the ecosystem if left untreated.

Waste is produced in the beginning of the washi tape life cycle where raw materials that are gathered. Many industries have used natural raw material, such as mulberry bark, to make paper. One of the main components in mulberry paper waste is cellulose. The cellulose waste can be used in many other products such as “many applications in food, cosmetics, pharmaceuticals, and detergents.” (Rachtanapun, 479) In order for the cellulose to become biodegradable, it must be modified to do so. After, the extraction of raw materials is completed the next waste material comes from the pulping.

When moving into creating the washi tape the paper component creates water waste from the pulping process of the raw material. Most of the wastewater that is from chemical pulping, where the wood chips are cooked until fibrous mass, contains wood debris and soluble wood materials. (Pokhrel, 38) These materials of lignin, carbohydrate, and extractives are hard to biodegrade as they continue onto the next stages of the paper making process. Other wastewater that is made from traditional methods, such as from the company Nasu in the prefecture of Ibaraki, contain about 13–15% sodium carbonate (Na2CO3). (Seki, 67) In traditional methods, the pulp is left in a ditch where the impurities are removed from the bark. These water waste have very harsh effects on the environment once they are poured out and left untreated.

The water waste has affected a different aspect of environments. These effects are not harmful towards humans, but they do affect the small organisms in the whole ecosystem. For example, there have been a few reports of the toxicity effects on fishes. The results have been shown to have “ respiratory stress, mixed function oxygenase activity, toxicity and mutagenicity, liver damage, or genotoxic effects, and lethal effects on the fishes to pulp and paper mill wastewater.” (Pokhrel, 41) This can be lethal to aquatic animals causes significant damages to its health. Another way it can affect the ecosystem is by changing the chemistry from the soil as it shows high levels of coliform bacteria. (Pokhrel) Even if there is coliform, it does not necessarily mean that it is a hazard to the ecosystem until it has been carefully looked at. As there is water waste created during the pulping process, there is waste that is created during the manufacturing process of leaching the fibers.

The next waste produced from paper making are the ashes that are from leaching to create lye that the pulp is boiled with. Leaching is a process that extracts materials from solids and creating it into liquids. This process is used to get lye which is a metal hydroxide. As lye is being created it can also form fly ashes and bottom ashes. Particle ashes are from coal combustion that either rise up or do not rise at all. They also have a Neutralization ability that can help to neutralize acidic soil or environmental problems. (Young-Sook et al, 475) Once lye is created, it then gets boiled with the pulp to remove the polymeric carbohydrate starches, fat, and polyphenolic biomolecules, tannin. The lye is then washed away to move onto the next stage that is bleaching.

Chemical waste is produced as the paper is being bleached for its signature white paper color. In many processes, chlorine and chlorine chemicals are the main ingredients to achieve a brighter color. Though, the byproducts created from using chlorine are “ toxic, mutagenic, persistent, and bioaccumulating and cause numerous harmful disturbances in biological systems.” (Bajpai, 148) However, there are changes in the industry that are trying to look more into more sustainable options that are chlorine free. One of the ways is oxygen bleaching where it “involves treating pulp with oxygen (from hydrogen peroxide), then ozone which is then washed with sodium hydroxide followed by an alkaline peroxide and sodium dithionite sequence” (Colbourne, 7) This procedure has some benefits as it does not release highly carcinogenic dioxins and the threat of lingering chlorine molecules. As the waste of the bleaching is undertaking, there is some waste that is produced from making the adhesive to create the washi tape product.

By adding the adhesive tape to the paper, it is an addition to the waste that is produced. Rubber based is one of the various types that is used to make the adhesive tapes. Though rubber based tapes are made from an organic compound from rubber trees, the waste can be harmful as it is created into other material. As the waste materials that are produced, they are “rich in crude protein and carbohydrates, causes environmental pollution” (Tripetchkul, Sudaut et al, 384) This can become a serious problem to countries that produce the natural rubber by creating a putrid and foul smell. These are the wastes that are created from the manufacturing process of the washi paper. The final waste and emissions from the finished washi tape product are the transportation from the workshop to the stores all over Japan or other counties.

Lastly, cars and ships can create emissions that get added to the waste production when sending out the washi tape product. A car can burn oil in order to run the motors but also creates emissions that are added to the ozone layer. As these emissions are added to the ozone it can contribute to the climate change problem that the Earth is facing. Ships are another transportation that creates pollution when transporting the washi tape products. Container ships can cause more damage than a singular car since they are larger in size and that they have to travel longer distances. These ships emit nitrogen oxide and sulfur oxide that adds into the atmosphere. These are the pollution, emission, and waste that has been created throughout a washi tape life’s cycle.

As a result, these different waste byproducts do have small effects on the environment. The raw materials waste from mulberry bark can create cellulose that can be reused in a day to day products like cosmetics and applications in food. The wastewater from the pulping process can have harsh effects on the environment because of how difficult to biodegrade the untreated water. Leaching ashes can have a Neutralization ability that can help to neutralize acidic soil or environmental problems. The bleaching process of Chlorine and Chlorine chemicals byproducts are toxic and can cause harmful disturbances in biological systems. Adhesive tape can be rubber based tape which can cause environmental pollution because it is rich in crude protein and carbohydrates. These are the waste products may be small but as time continues, it can become a terrible issue on the environment. Slowly, companies are trying to figure out how to convert the old traditional methods into ways to make it more sustainable.

Bibliography

Abe, Kentaro & Yan, Hiroyuki “Comparison of the characteristics of cellulose microfibril aggregates isolated from fiber and parenchyma cells of Moso bamboo (Phyllostachys pubescens)” Cellulose, Volume 17, Issue 2, SpringerLink, April 2010, pp 271–277, link.springer.com/article/10.1007/s10570-009-9382-1

Bajpai, Pratima“Application of Enzymes in the Pulp and Paper Industry” TOPICAL PAPER, 15, Biotechnol. Prog. 1999, 04 September 2008, 147−157, doi.org/10.1021/bp990013

Biermann, Christopher J. “Handbook of Pulping and Papermaking” An Imprint of Elsevier Second Edition, Academic Press, 1996, pp 283-295

Colbourne, Jane & Hori, Manami “Modern machine–made washi and the implications for contemporary conservation practice” Northumbria Research Link, Journal of the Institute of Conservation, 13 July 2015, Pages 1-21, core.ac.uk/download/pdf/46611441.pdf

M. Inaba & R. Sugisita “Permanence of washi (Japanese paper)” Studies in Conservation, vol. 33, issue 1, Taylor & Francis,19 July 2013, pp. 1-4, doi.org/10.1179/sic.1988.33.1.1

Rachtanapun, Pornchai & Tongdeesoontorn, Wirongrong “Effect of glycerol concentration on sorption isotherms and water vapour permeability of carboxymethyl cellulose films from waste of mulberry paper “ Asian Journal of Food and Agro-Industry, Food Innovation Asia, 2009.

Saburo, Inokawa “Studies on the Mucilage of the Root of “ Tororo-aoi” (Abelmoschus manihot, MEDIC). I. On the Characteristic Colloidal Nature of the Mucilage” Bulletin of the Chemical Society of Japan, Vol.33, No.11,The Chemical Society of Japan, 1960, doi.org/10.1246/bcsj.33.1473

Seki, Masazumi “Database of Traditional Papermaking Centers in East Asian Regions” Kochi Prefectural Paper Technology Center, Vol. 85, SENRI ETHNOLOGICAL STUDIES, 25 December 2013, pp 61-81, doi.org/10.15021/00002429

Tripetchkul, Sudaut et al “Ethanol Production by Zymomonas mobilis Using Natural Rubber Waste as a Nutritional Source” Journal of Fermentations and Bioengineering, Vol. 74, No. 6, Elevier, 1992 ,pp 384 - 388, doi.org/10.1016/0922-338X(92)90036-T

Young-Sook, Shim, Seung-Whee Rhee & Woo-Keun “Comparison of leaching characteristics of heavy metals from bottom and fly ashes in Korea and Japan” Waste Management, vol. 25, issue 5, Elsevier, 2005, pp. 473-480, doi.org/10.1016/j.wasman.2005.03.002

Pokhrel D. & Viraraghavan T. “Treatment of pulp and paper mill wastewater—a review” Science of The Total Environment, Vol, 333, issues 1-3, Elevier, 15 October 2004, pp 37-58, doi.org/10.1016/j.scitotenv.2004.05.017

Ramirez 1

Glendy Ramirez

DES 40A

Professor Cogdell

6 December 2018

Life Cycle of Washi Paper – Energy

Although china invented what is now paper the handcrafted and craftsmanship of paper

later was introduced to Japan by Buddhist monks in 610 AD. They started to make their own

form of paper which turned to be very impressive, unique in color, texture and design. Paper in

Japan is known as “washi”. Washi which stands for “wa” meaning Japanese and “shi” meaning

Paper together as Japanese Paper. The video ”Washi. Craftsmanship of Traditional Japanese

Handmade Paper” mentions how Washi making was passed down by ancestors and kept by 3

communities who take pride of this tradition. Washi is most naturally done, all entirely done by

hand. “Families and their employees work under masters who have inherited the techniques from

their parents. The communities play roles in keeping this craftsmanship viable, ranging from the

cultivation of mulberry, training in the techniques and the creation of new Washi products”.

However, Europe and the western side in general was introduced to paper making and used paper

making technology to make their own paper quicker and cheaper. People started buying the

paper the “Western way” rather than handmade. According to the Japanese Paper Place “About

Washi”, “As Japan rushes with the rest of the world into the 21st Century, and more modern

technologies take over, machines produce similar-looking papers which have qualities very

different from authentic Washi. As of the fall of 2008, there remained fewer than 350 families

still engaged in the production of paper by hand”. Because of this, the few Japanese paper

making families market went down and compete with Indian handmade paper. Also because of

manufacture Washi tape has turned to be popular, “ Japanese Washi tape products are most

Ramirez 2

popular in North America, Domestic Market, and Southeast Asia”, (Alibaba). Looking at the

handed crafted craftsmanship of Washi and Washi tape manufactured in the U.S, we will see

how it differs in energy and production.

To understand the handcrafted art of Washi, we need to see what it is made of. According

to the source“About Washi”, the three main plants (raw materials) are kozo, mitsumata and

gampi. The Kozo plant (paper mulberry) is thick and strong, and it is the main material used.

Mitsumata: very delicate element, takes longer to grow, which is why it can make it expensive.

Gampi the“noblest fiber” noted for its richness, dignity and longevity. Gampi has a natural 'sized'

finish which does not bleed when written or printed on. These fibers are all native to Japan, and

are used in making Washi, while there are other fibers such as hemp, abaca, rayon, horsehair,

and silver or gold mixed together with the others for decorative effect. Now that we know what

are the raw materials, they are made is in the hands of the families who inherited this tradition.

The tools used and the energy used to make Washi is kinetic energy/mechanical energy,

mostly because is done using human labor, very carefully done. “They require no help, and are

proud of to do it”, from the video, “ Washi: Craftsmanship of Traditional Japanese Handmade

Paper”. Branches of Kozo, (mulberry) plant are trimmed down, collected into piles, enough to

make a good amount of paper. Then they are soaked in warm water of hot water to make

branches easy to remove and the tough pliant inner bark is separated. Individuals clean out

impurities one by one by hand and have some time to socialize with one another, and get to

know each other, a time of community and culture embrace. Using a wood shaped hammer,

someone pounds and stretches the fiber until it is turned into a “paste” form and goes through a

liquid transformation. The “paste” is spread and placed into a bamboo mesh screen called “su” to

form each sheet. The “su” is constantly being dipped in the “paste” multiple times using hand

motion for each sheet and piled on top of each other. Solar energy and thermal energy are also

Ramirez 3

used for the finishing part of the production. The sheets are laid on wood and placed outside to

dry with the sun's light and air to be more naturally done. And or it can also be dried by using a

heated dryer. Once they are dried, they are inspected for paper quality, color, thickness through

the “elimination process”, the imperfect ones are eliminated. Because of paper making

technology and manufacturing the production of Washi became widely known for westerners,

and started to add adhesives.

Today Japanese paper production has changed by paper making technology and added

more elements. According to the journal “Culture of Heritage” by Dario Battistel Japanese paper

is ambiguous,“Nowadays, the term ‘Japanese paper’ is rather ambiguous as it includes materials

made using oriental fibers, chemical wood pulp as well as non-oriental fibers, such as Manila

hemp, that are sometimes used by several producers for containing the production costs… These

non-oriental fibers typically contain higher amount of lignin with respect to Japanese fibers”,

(Battistel,1). There are also adhesives that are added to Washi tape, but the first tape made was

the Scotch masking tape which is the most famous tape brand that also sells Washi tapes as well.

It is said that Washi tape is similar to masking tape and it comes off like masking tape a doesn’t

leave a mess. “Richard Drew invented masking tape and transparent cellophane tape, the first

modern pressure sensitive tapes”, (Invent). After Drew invented adhesives later the tapes were

produced, to clear, to ducked tape. Mass production uses steam engines to power the machines to

make the adhesives for tapes and could possibly be the same for Washi tape. The Scotch brand

for example gets their adhesives made in China for the 3M company. “The adhesive can be

silicon, rubber or acrylic depending on the brand”, (Wishy Washi). There wasn’t much of a clear

way in how the Washi paper was transported, but it may have been transported by boats and or

ships, to the US and other part in the world. Once they are done, they are sent by trailers possibly

and delivered to outlets, and shelves where we can purchase them. 3M is the company that

Ramirez 4

distributes Scotch tapes including Washi tape to stores like Target, Walmart, and many more.

Machines could be the ones doing the energy since they are manufactured, the Washi itself is by

hand but the rest is by manufacture. Using fossil fuels to power machines and kinetic energy for

packaging and sending to stores. There are other suppliers and manufactures such as global

trader, Alibaba. The production has more variety due to mass production, on the website it

mentions what they offer, “A wide variety of Japanese washi tape options are available to you,

such as pressure sensitive, water activated, and hot melt. You can also choose from masking,

carton sealing, and bag sealing. As well as from waterproof, heat-resistant, and antistatic. And

whether Japanese Washi tape is acrylic, rubber, or silicone”, (Alibaba). Now that it is accessible,

washi tape now is used by many, for decorative purposes, on notebooks, used for artwork, and

many other crafts as the Washi process itself is a craft in the traditional way.

Paper making has come a long way and Japanese Paper Washi Craftsmanship as well.

According to “Washi: The Art of Japanese Paper” by Nancy Broadbent Casserley there is a

culture and appreciation and contribution of Washi for Japanese culture,“...handmade Japanese

paper, and its role in the domestic, spiritual, and cultural life of Japan. The history and diversity

of this 1400-year-old craft…”. The people of the three different communities in Japan are the

only ones left in passing this tradition to their families. The process of making Washi is a long,

but a meaningful process of the people who take pride and use their energy into making of this

paper. Long after it was known due to manufacturing that adhesives were introduced in adding to

Washi. It is available in many colors and used in arts and crafts. The production is both kinetic,

and may use fossil fuels since it is manufactured to add adhesives, and a variety of designs on it

to be used in a creative way. Today the production in the Western side has added more elements

than the natural way and could be questioned if is is Eco friendly or not, however according to

Wishy Washi, “When it comes to Washi tape being Eco friendly we consider the

Ramirez 5

alternatives...which is duct (duck) tape. Duct tape's contents, and process for manufacturing, are

extremely more harmful to the environment, does not biodegrade (although we have noticed a

new duct tape on the market that claims to biodegrade within 15 years and yet another that is

using soy oil for adhesive), cannot be reused and tends to leave a rather sticky mess when

removed”. Having the production of Washi in Western side and Eastern side, we can see how

technology and energy has changed and helped to expand the knowledge of Washi tape and

maybe others who are curious can learn about the art Washi’s history.

Ramirez 6

Bibliography

“About 3M.” About 3M | 3M United States, www.3m.com/3M/en_US/company-us/about-3m/.

October 29, 2018

About Washi by The Japanese Paper Place, www.japanesepaperplace.com/abt-japanesepaper/

about-washi.htm. October 29, 2018

Affairs, Japan. Agency for Cultural. “Washi. Craftsmanship of Traditional Japanese Handmade

Paper.” UNESCO Multimedia Archives, Japan. Agency for Cultural Affairs Producer., 1

Jan. 1970, www.unesco.org/archives/multimedia/?pg=33&s=films_details&id=3666.

Battistel, et al. “Evaluation of the Volatile Organic Compound Emissions in Modern and

Naturally Aged Japanese Paper.” Journal of Cultural Heritage, vol. 33, 2018, pp. 18–29.

Donohue, Nanette. “Cerruti, Courtney. Washi Tape: 101 Ideas for Paper Crafts, Book Arts,

Fashion, Decorating, Entertaining, and Party Fun!” Library Journal, vol. 139, no. 12,

2014, p. 88.

“Inductee Detail.” National Inventors Hall of Fame, www.invent.org/honor/inductees/inducteedetail/?

IID=329. October 29,2018

“Japanese Washi Tape.” Japanese Washi Tape, Japanese Washi Tape Suppliers and

Manufacturers at Alibaba.com, www.alibaba.com/showroom/japanese-washitape.

html?searchweb=Y&. October 29,2018

Singh, Ruchika Wason. "Washi: the art of Japanese paper by Nancy Broadbent Casserley."

(2016): 160-160. October 29, 2018

Smith, Merrily A, et al. “Pressure-Sensative Tape and Techniques For Its Removal From

Paper.”

Wishy Washi Tape. “What Is Washi Tape?” Wishy Washi Tape, www.wishywashi.com/what-iswashi-

tape.October 29,201