Design Life-Cycle

assess.design.(don't)consume

Ryan Lazzareschi

SAS 43

Professor Cogdell

6 December 2018

Life Cycle of Amazon Echo Dot: Raw Materials

Consumer electronics have witnessed a boom in the last half century. In this time period, computer microchips have become exponentially more powerful and some can even compute billions of operations per second. This sharp increase in processing power has allowed computer microchips to tackle incredibly complex tasks. Thus, we have entered the age of smart technology and artificial intelligence, where computers can now exhibit human levels of intelligence. Sadly, humans are increasingly becoming attached to technology and veering away from human to human interaction. However, humanity still wants to feel human-like interaction, hence the rise of one of the internet’s most popular products, the Amazon Echo Dot.

At its core, the Echo Dot is imitating a person that can answer your every request, and achieves this by using Amazon’s voice service, Alexa. The parallel between speaking to a real human and Alexa is rather scary; a consumer can ask Alexa a question just as they would ask a person, and a second later, Alexa formulates a detailed answer just like a person would. On top of that, since it is connected to the internet, the Echo Dot can also control a variety of devices in the household, from lights to appliances to televisions. All this functionality comes at a deceivingly low cost of fifty dollars, and oftentimes even lower. But society fails to consider the true costs of technological products like the Echo Dot. The life cycle of the Amazon Echo Dot Dot consumes rare earth metals that are nearly impossible to recycle. Amazon will have to reconsider the materials they use to manufacture the Amazon Echo Dot within the next decade, or Amazon will have to stop production of the Echo Dot.

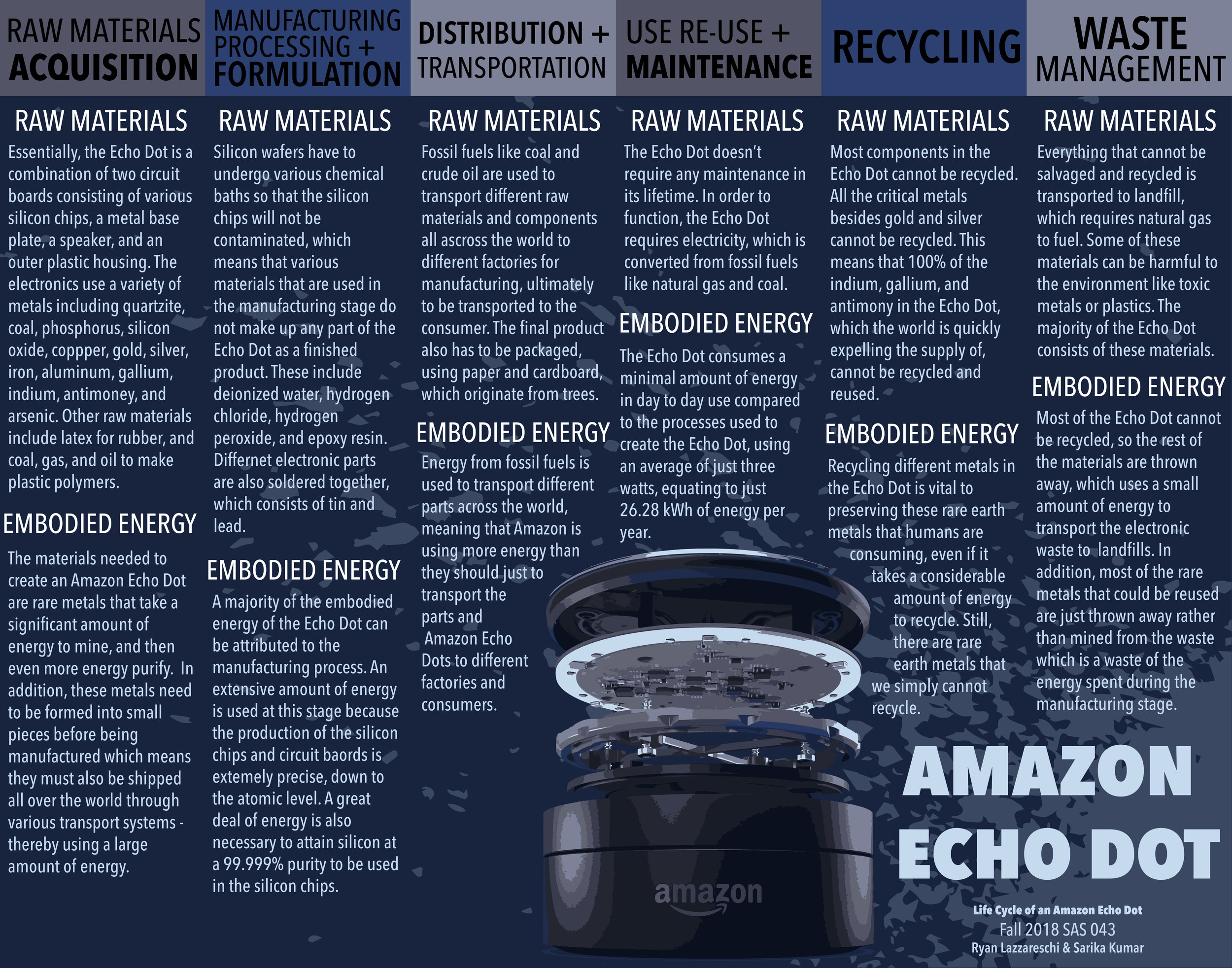

Although Amazon is the maker of the Echo Dot, it is actually a combination of various companies working together to deliver a finished product. Essentially, the Echo Dot is a multitude of simpler finished products working together to make a final product. It is a combination of two circuit boards, a metal base plate, a speaker, and an outer plastic housing. The circuit boards are composed of different chips, including a digital media processor, SDRAM, flash memory, wifi and bluetooth chip, digital audio convertor, LED drivers, low-power stereo ADC, and duals positive-edge-triggered D-type flip flops. These all functionally perform different tasks, but they are all Silicon chips and use the same general materials to construct. Some of the companies that make these chips are Qualcomm, Samsung, and Micron, but the biggest manufacturer is Texas Instruments, who are responsible for half of the chips and semiconductors found in the Echo Dot.

Manufacturers have to perform an extensive process to turn raw materials into silicon chips. It starts with polysilicon, which is derived from quartzite and coal. This quartz is mined from the earth, which uses fossil fuels to supply the energy to extract quartzite, along with every other metal used in production of the Echo Dot. The mined quartzite is then melted and crystallized, and drawn out in a long cylinder. Silicon wafers are then created from cutting this cylinder with diamond. Phosphorus is then added and a layer of glass, silicon oxide, is grown on the surface. Patterns are etched on the silicon wafer using photolithography, and the glass is removed where the pattern was etched. Boron and arsenic are then used to adjust the conductivity of the wafer. Since this entire process occurs on the microscopic level, necessary precautions must be taken in order to have functional microchips. Humans are covered from head to toe, so they won’t contaminate any of the chips, and the factories use extensive circulation systems to keep the air in the factories nearly a hundred times cleaner than a hospital. The silicon wafers are then distributed to specialized factories to turn the wafers into specific chips with different functions. The wafers then undergo different platings and chemical baths. The wafers are cleaned using sulfuric acid and hydrogen peroxide. To remove any unnecessary particles, ammonium hydroxide and hydrogen peroxide are used. Another contamination removal bath uses deionized water, hydrogen chloride, and hydrogen peroxide. Packing millions of transistors onto a small silicon wafer is a very precise process, so even a dust particle can destroy an entire chip, so each of these cleaning processes ensures that a dust particle will not contaminate the chips. All these contamination baths are part of the reason why computer chips use the most energy per kilogram to make, and why they use a multitude of materials that do not actually make up the Echo Dot.

Even though silicon chips are the brains of the Echo Dot, they have to be connected in order to work together. This is where printed circuit boards are used. Generally, printed circuit boards are made of four distinct layers, which are laminated together using heat into one layer. “The material used in PCB from top to bottom includes Silkscreen, Soldermask, Copper and Substrate” (PCBCART). The substrate cards are assembled using surface wiring and other wiring throughout the card, which is largely made by copper. The components are placed into the holes and soldered into place. Soldering paste, made of tin and lead, connects the surface components, and the soldering paste is run through these holes. The printing blades spread the soldering paste on the stencil, running through the holes and covering the metallic surfaces of the printed circuit board, which establishes an electric current. Using precise machines, surface wiring elements are then installed. The most essential part of this process is in an oven where the heat solders the different components on the circuit board to the card. Humans then insert different circuit connectors through the card and into their respective holes. The metallic placement points are soldered to the card, done with a bath of molten tin-lead alloy at a very high temperature. In this process, there is also a minimal amount of silver and gold being used in the circuitry. The final product is a working circuit board that will be transported to a different factory to assemble the Echo Dot.

Other smaller components are also vital to the Echo Dot, and not nearly as complex as the silicon chips or circuit boards inside the Echo Dot. For example, Alexa is able to speak to humans using a speaker in the Echo Dot. The speaker is manufactured using stamped iron or aluminum for the frame, iron oxide, strontium, and ceramic for the magnet, and copper wire and adhesive glue. Another small component are light-emitting diodes, better known as LEDs used to indicate certain states of the Echo Dot. In order to create light, LEDs are made of aluminum, gallium, indium, copper, antimony, arsenic, nitrides, and phosphides. The housing for the LEDs are constructed from glass, silicone, steel, or fiberglass. Even this seemingly negligible component, in comparison to chips and the circuit boards, is expelling supplies of rare earth metals like antimony, gallium, and indium.

Once all of these separate electronic components are made, they are shipped to Foxconn in China for the final stage of manufacturing, where each component will be put together to create a finished product. At Foxconn, the rest of the manufacturing process for the Echo Dot is done by hand and with soldering irons. The only other components not accounted for are the only non-technological components. These include a metal base plate that serves as a weight and frame for the Echo Dot, a plastic housing to hide all the electronic components, a rubber bottom to prevent scratches, and screws in order to hold all the different components together. The metal plate is made of steel, which is an alloy composed of iron and carbon. The plastic housing is made of polymers, derived from materials like coal, gas, oil, and different minerals and plants. The rubber is either natural, made from latex which is grown from plants, or synthetically made, for example styrene butadiene or polyacrylics. Lastly, the screws are made of carbon and steel wire. A small amount of glue and more solde is used to hold all the small components together, resulting in a finished Amazon Echo Dot.

Even though the Echo Dot may be fully constructed, it still has to be packaged and shipped to consumers. The Echo Dot is packaged with cardboard and paper, which uses trees as the raw material. These units are also shipped overseas from China to the United States and any other distributing centers across the world. This requires fossil fuels to transport the Echo Dots to carrier facilities, and more fossil fuels are expelled to ship the units to the buyer’s residence. Once the Echo Dot is in the buyer’s hands, there is no need for maintenance at any point in its lifetime. The only requirement is that it needs electricity to operate, so it must plugged into an outlet. The minimal amount of electricity used by the Echo Dot still needs to be taken into account, as more fossil fuels are converted to electricity for the consumer to use, unless the residency uses solar power. Once the Echo Dot reaches the end of its lifetime, the Echo Dot should be recycled and disposed of at appropriate electronic waste sites. Sadly, the vast majority of materials within the Echo Dot cannot be recycled; this includes all of the critical metals inside the device besides gold and silver, which can be recycled. This means that some of the rarest metals on earth, including indium, gallium, and antimony are wasted and unable to reused. The rest of the Echo Dot, including the plastic housing, rubber bottom, and most of the electronic components are transported to landfills. This however is only one of the major issues regarding the life cycle of the Echo Dot.

The biggest issue regarding the Echo Dot is debatably in the manufacturing stage. Manufacturing the Amazon Echo Dot comes at a widely unknown price, a price that cannot be described by a number. In the final stage of manufacturing, which is done by Foxconn, workers are oppressed and forced to work in harsh conditions. These factories exhibit “poor working conditions and high rates of suicide among its workers” (Weise). Amazon’s success has come at the expense of these Foxconn workers, who should not have to withstand these harsh conditions to supply Amazon with a viable amount of Echo Dots to sell to consumers. “China Labor Watch reported that up to 40% of its workforce has been made up of temporary workers, far exceeding a legal limit of 10%. These temp workers received inadequate safety training, weren’t paid extra for overtime and didn’t get paid sick leave, according to the report” (Roettgers). Workers are also subject to excessive overtime hours, some days even having to work fourteen hours straight. As this relatively recent Foxconn news is reaching the mass media, Amazon will have to change its working conditions for their manufacturing processes.

Like most electronic devices, the Amazon Echo Dot uses a plethora of materials, ranging from some of the most abundant materials like wood to some of the rarest earth metals like indium and gallium. A majority of the materials that are used in the life cycle of the Echo Dot are found in the manufacturing process, since manufacturing silicon chips and circuit boards are very material intensive. At this rate though, Amazon will not be able to produce the Echo Dot within the next couple decades unless they find supplements for these critical metals soon. Amazon also needs to become more eco-friendly as most of the energy in the Echo Dot’s life cycle is supplied by fossil fuels, which are also depleting quickly. Amazon can be more environmentally friendly by switching from currently used nonrenewable energy sources to renewable energy sources. The most important issue that Amazon needs to settle as of right now though is the harsh working conditions that Foxconn employees face everyday in China. Amazon is far from perfect and even though they are dominating the online market with flagship products like the Echo Dot, Amazon must take the necessary measures to make sure they are an ethical and environmentally friendly company.

Bibliography

“Amazon Echo Dot Teardown.” IFixit, 29 June 2017, www.ifixit.com/Teardown/Amazon Echo Dot Teardown/61304.

“CN108550367A - Kinds of Portable Intelligent Voice Interaction Control Device, Method and System.” Google Patents, Google, 18 May 2018, patents.google.com/patent/CN108550367A/en?q=dot&oq=amazon echo dot.

“DM3730, DM3725 Digital Media Processors.” Texas Instruments, Texas Instruments, July 2011, www.ti.com/lit/ds/symlink/dm3725.pdf.

Dupzyk, Kevin. “Things Come Apart: The Amazon Echo.” Popular Mechanics, Popular Mechanics, 2 July 2018, www.popularmechanics.com/technology/gadgets/a25106/amazon-echo-disassembly/.

Hughes, Mark. “Teardown Tuesday: Amazon Echo Dot v2.” All About Circuits, 1 Nov. 2016, www.allaboutcircuits.com/news/teardown-tuesday-amazon-echo-dot-v2/.

Johnson, Bernadette. “How Amazon Echo Works.” HowStuffWorks, HowStuffWorks, 16 Nov. 2016, electronics.howstuffworks.com/gadgets/high-tech-gadgets/amazon-echo1.htm.

Kinsella, Bret. “Apple HomePod Costs $216 to Manufacture.” Voicebot, 15 Feb. 2018, voicebot.ai/2018/02/15/apple-homepod-costs-216-manufacture/.

“Light-Emitting Diode (LED).” How Products Are Made, www.madehow.com/Volume-1/Light-Emitting-Diode-LED.html.

Lloyd, Craig. “How Much Electricity Does the Amazon Echo Use?” How-To Geek, How-To Geek, 10 Apr. 2018, www.howtogeek.com/348219/how-much-electricity-does-the-amazon-echo-use/.

“OK Google, How Much Energy Does Alexa Consume?” OK Google, How Much Energy Does Alexa Consume? | E Source, 20 Feb. 2017, www.esource.com/es-blog-2-17-17-voice-control/ok-google-how-much-energy-does-alexa-consume.

“PCB Materials.” PCB Manufacturing Process – A Step by Step Guide | PCBCart, www.pcbcart.com/pcb-capability/pcb-materials.html.

Roettgers, Janko. “Amazon Criticized Over Working Conditions at Echo Factory.” Variety, Variety, 11 June 2018, variety.com/2018/digital/news/amazon-echo-foxconn-working-conditions-1202840512/.

“Screw.” The Columbia Encyclopedia, 6th Ed, Encyclopedia.com, 2018, www.encyclopedia.com/science-and-technology/technology/technology-terms-and-concepts/screw.

“Stereo Speaker.” How Products Are Made, www.madehow.com/Volume-7/Stereo-Speaker.html.

Swearingen, Jake. “Amazon Could Give the Echo Dot Away and Still Make Money.” Intelligencer, 3 Jan. 2018, nymag.com/intelligencer/2018/01/amazon-could-give-the-echo-dot-away-and-still-make-money.html.

“TPS65910xIntegratedPower-Management Unit TopSpecification.” Texas Instruments, Texas Instruments, Oct. 2014, www.ti.com/lit/ds/symlink/tps65910.pdf.

Weise, Elizabeth. “Amazon's Echo Dot, Kindles Made in Foxconn Factory Rife with Labor Abuses, Rights Group Says.” USA Today, Gannett Satellite Information Network, 12 June 2018, www.usatoday.com/story/tech/talkingtech/2018/06/11/amazons-echo-dot-kindles-made-factory-where-workers-were-abused/690175002/.

“What Are Plastics?” Plastics Make It Possible, 29 Oct. 2018, www.plasticsmakeitpossible.com/about-plastics/types-of-plastics/what-are-plastics/.

Williams@wwwdotandrew, Andrew. “How Much Power Does Your Smart Home Tech Really Use?” The Ambient, 28 Feb. 2018, www.the-ambient.com/features/power-smart-home-tech-yearly-cost-374.